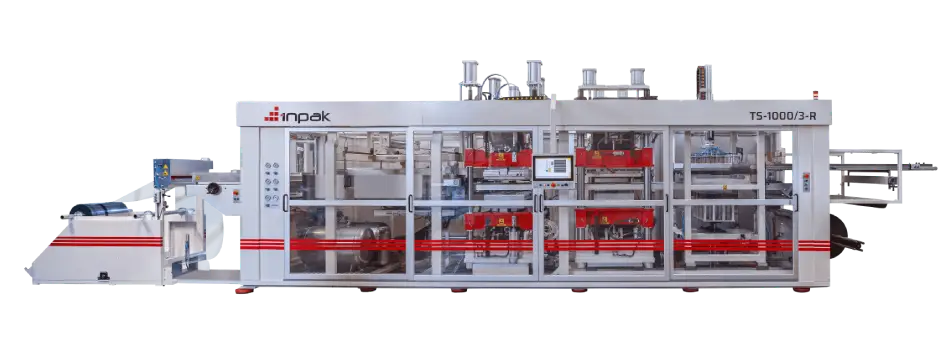

TS-1000 Thermoforming Machine: Excellence in Thermoform Packaging

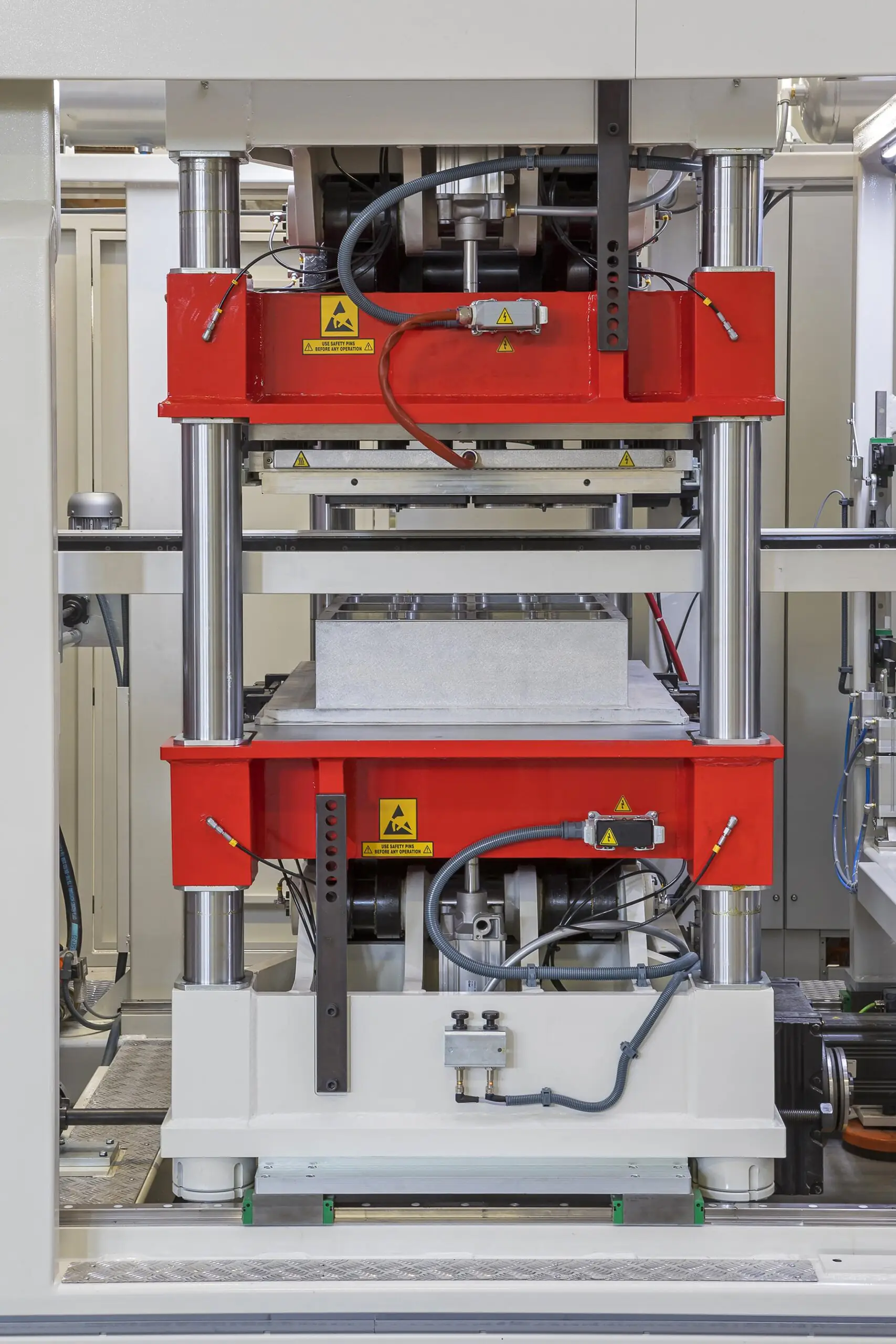

The TS-1000 Thermoforming Machine by INPAK is designed to set new standards in the plastic packaging industry. Engineered for businesses seeking reliability, speed, and precision, this advanced thermoforming packaging machine seamlessly integrates cutting-edge technology with exceptional performance, making it a top choice for high-volume production needs.

High-Performance Specifications for Advanced Production

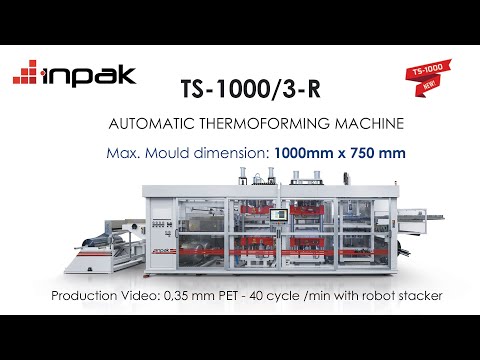

The TS-1000 Thermoforming Machine offers unmatched flexibility and precision, ensuring superior results across a wide range of thermoforming packaging applications. Key specifications include:

- Maximum Mold Dimensions: 1000 x 750 mm, accommodating larger and more complex packaging designs.

- Cycle Speed (Dry Cycle): Up to 70 cycles per minute for fast and consistent output.

- Maximum Sheet Width: 1040 mm, perfect for larger thermoforming plastic sheets.

- Material Compatibility: PET, CPET, PP, PVC, PS, OPS, PLA, supporting diverse production needs with a maximum sheet thickness of 1.5 mm.

This versatile thermoforming machine is ideal for producing a wide variety of thermoforming products, from thermoform packaging for food to industrial-grade plastic components.

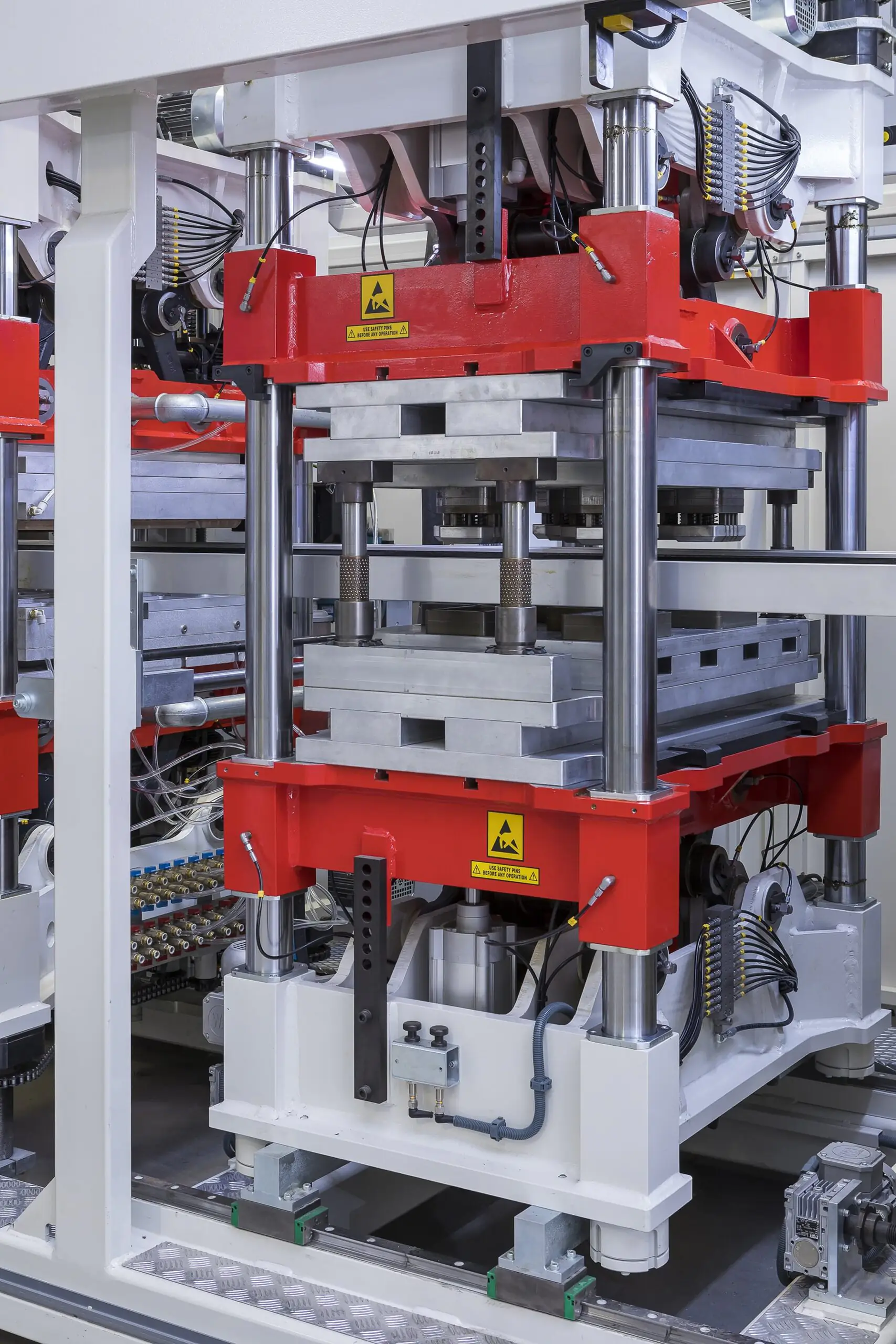

Energy Efficiency and Robust Power

The TS-1000 Thermoforming Machine is designed with energy efficiency in mind. Key power specifications include:

- Power Consumption: 40–75 kW, optimized for cost-effective long-term use.

- Total Installed Power: 190–220 kW, ensuring reliable and continuous operation.

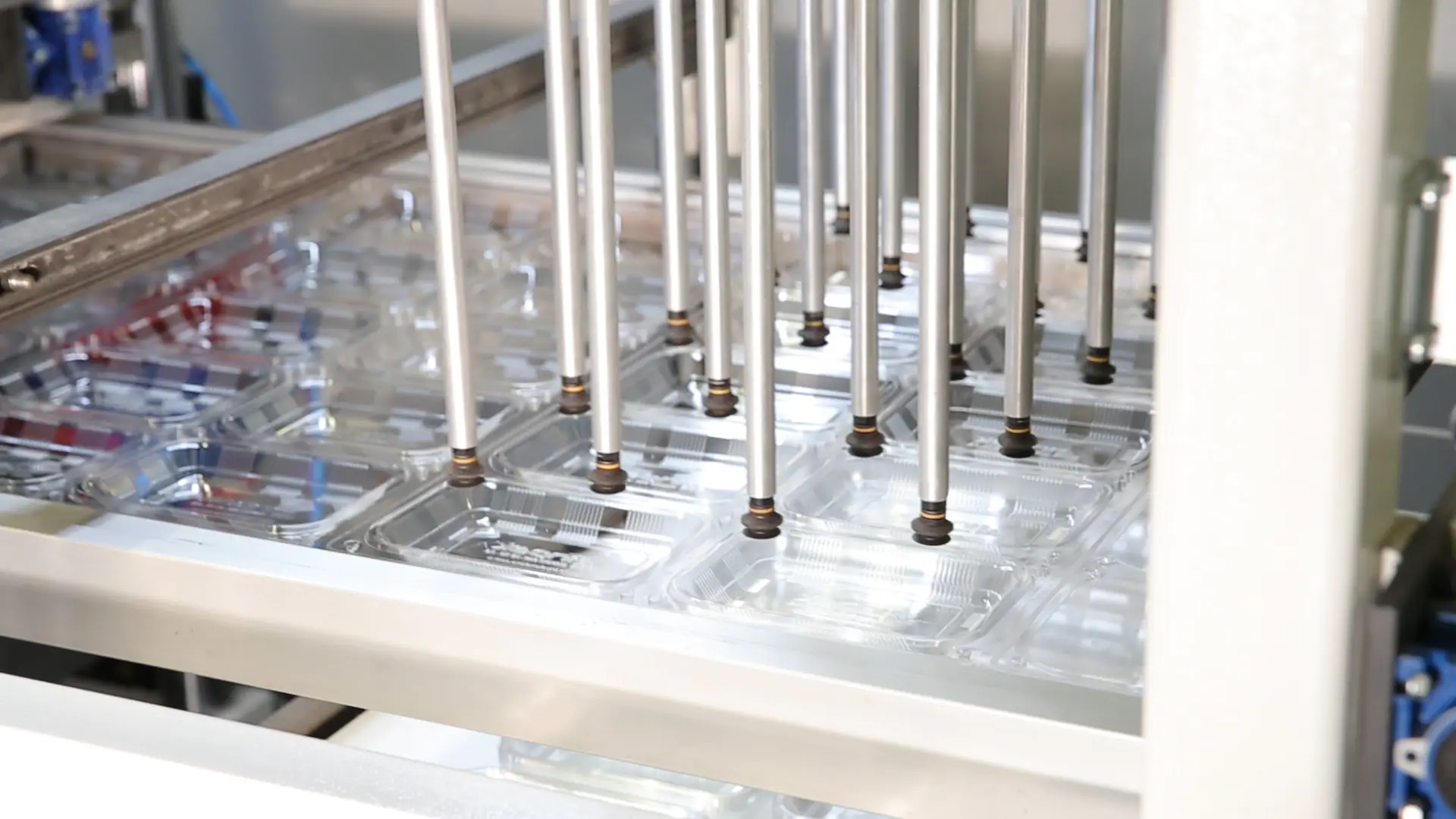

- Vacuum Pump Capacity: 200 m³/h, enhancing accuracy and efficiency in vacuum forming machine processes.

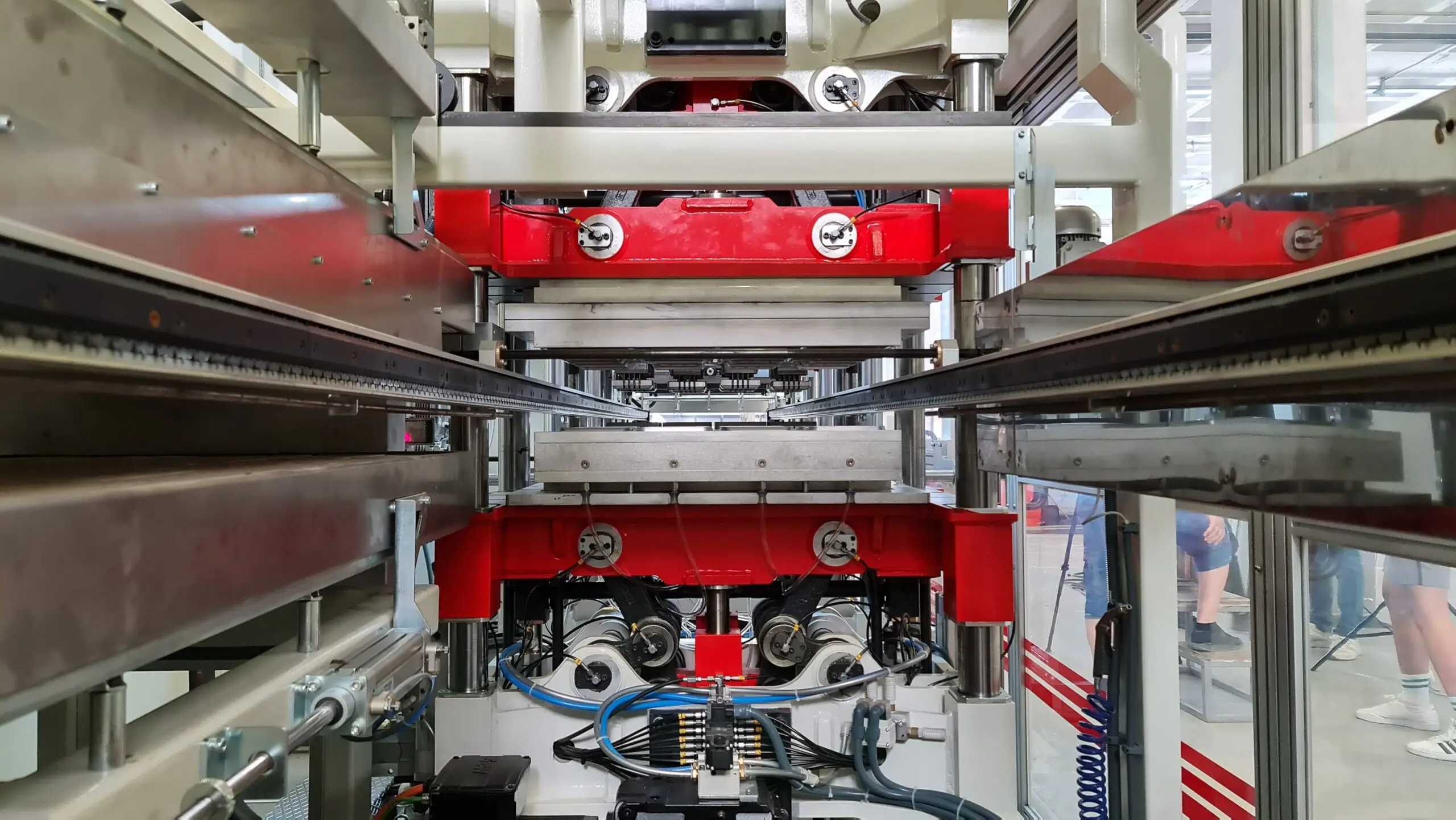

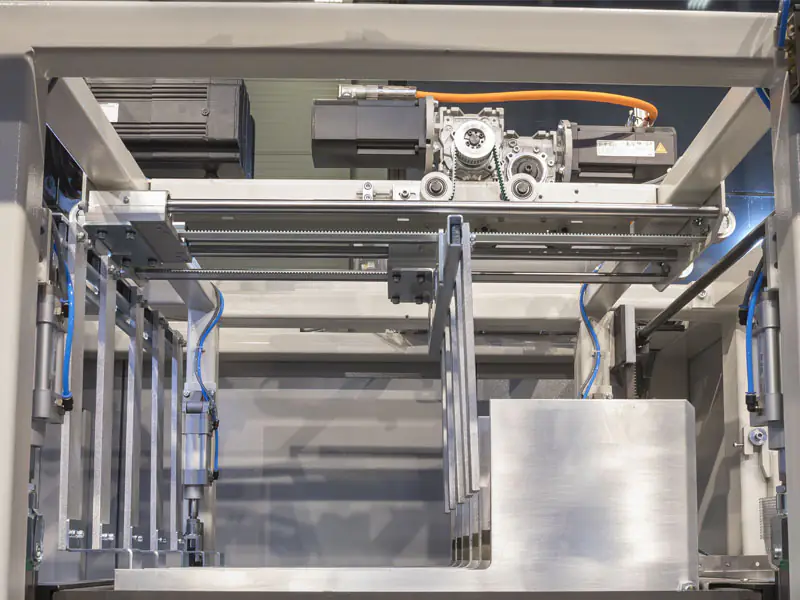

Advanced Technology for Seamless Operation

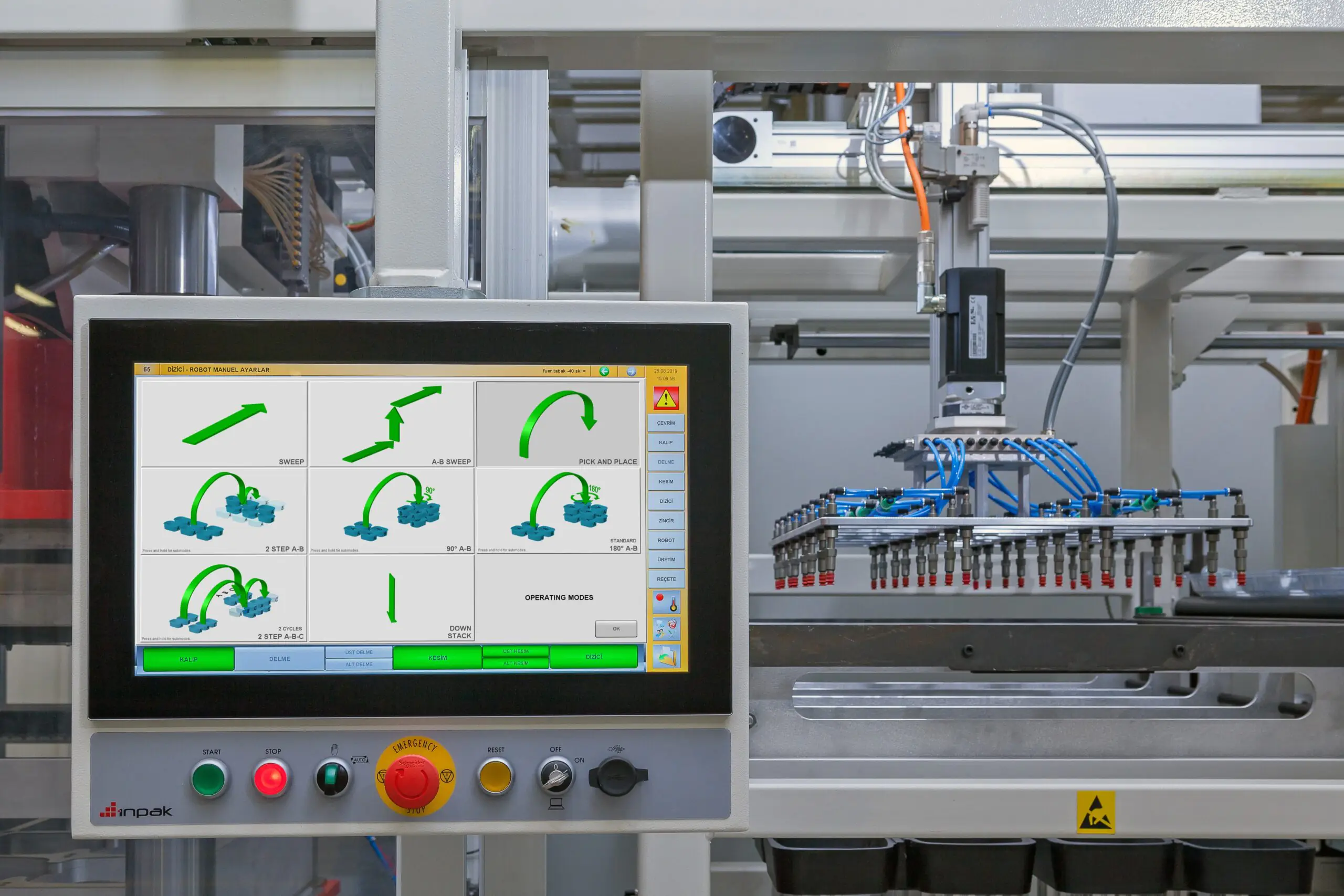

The TS-1000 features a B&R Industrial PC as its control unit, providing superior automation and operational reliability. The 18.5-inch B&R Colorful Touch Screen allows for intuitive monitoring and adjustments, enhancing user experience. The centralized lubrication system, powered by BEKA-MAX, ensures smooth operation and reduces maintenance requirements.

Why Choose INPAK for Thermoforming Machines?

As a leading thermoforming machine manufacturer, INPAK is dedicated to delivering advanced solutions for the plastic packaging industry. From custom thermoforming to industrial-scale production, our machines are tailored to meet the most demanding requirements. The TS-1000 exemplifies our commitment to energy efficiency, innovation, and user-friendly design.

Transform Your Business with the TS-1000

The TS-1000 Thermoforming Machine is more than a piece of equipment—it’s a solution designed to elevate your production capabilities. Whether you need a large vacuum forming machine for industrial applications or a high-speed thermoforming packaging machine for food products, the TS-1000 delivers unparalleled performance and reliability.

Choose INPAK for your thermoforming needs and experience the future of plastic packaging technology. Contact us today to learn more about how the TS-1000 can revolutionize your business.