Thermoforming Machine: Revolutionizing Plastic Packaging Machine Industry

The thermoforming machine has become a cornerstone in the plastic packaging machine industry, providing cutting-edge solutions for businesses involved in food packaging machines and other packaging sectors. Designed to enhance efficiency, precision, and sustainability, thermoforming machines are a game-changer for manufacturers aiming to stay competitive in today’s market.

Our Thermoforming Machines

At INPAK, we take pride in offering a comprehensive range of thermoforming machines designed to meet diverse packaging needs. Below is a list of our advanced thermoforming machines:

- TSR-800 Thermoforming Machine

- TS-800 Thermoforming Machine

- TS-850 Thermoforming Machine

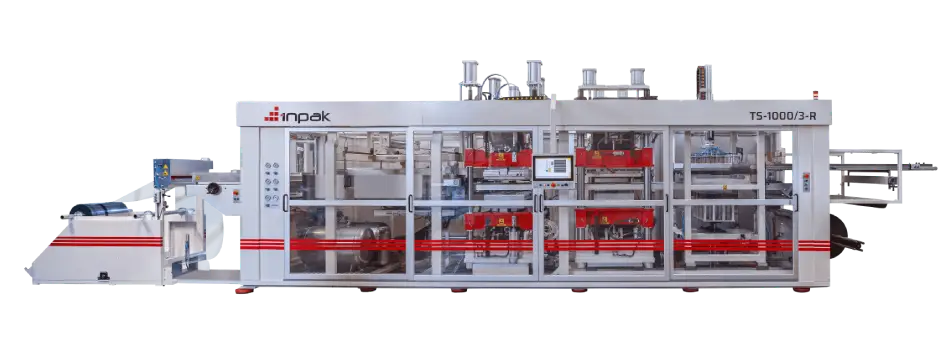

- TS-1000 Thermoforming Machine

- Pre-Heater Thermoforming Machine

- Elevator Conveyor System for Thermoforming Machine

Each of these machines is engineered for efficiency, precision, and durability, making them ideal for various industries including food, medical, and industrial packaging. Contact us to learn more about how our thermoforming machines can enhance your production processes!

Why Choose a Thermoforming Machine for Your Business?

Thermoforming machines are essential for producing high-quality thermoforming products, ranging from thermoform packaging to thermoformed food packaging. These machines offer:

- Versatility: Ideal for various industries such as food, medical, and industrial packaging.

- Custom Thermoforming: Tailored solutions for businesses with unique packaging needs.

- Cost-Effectiveness: Energy-efficient designs reduce operational costs, making them a smart investment.

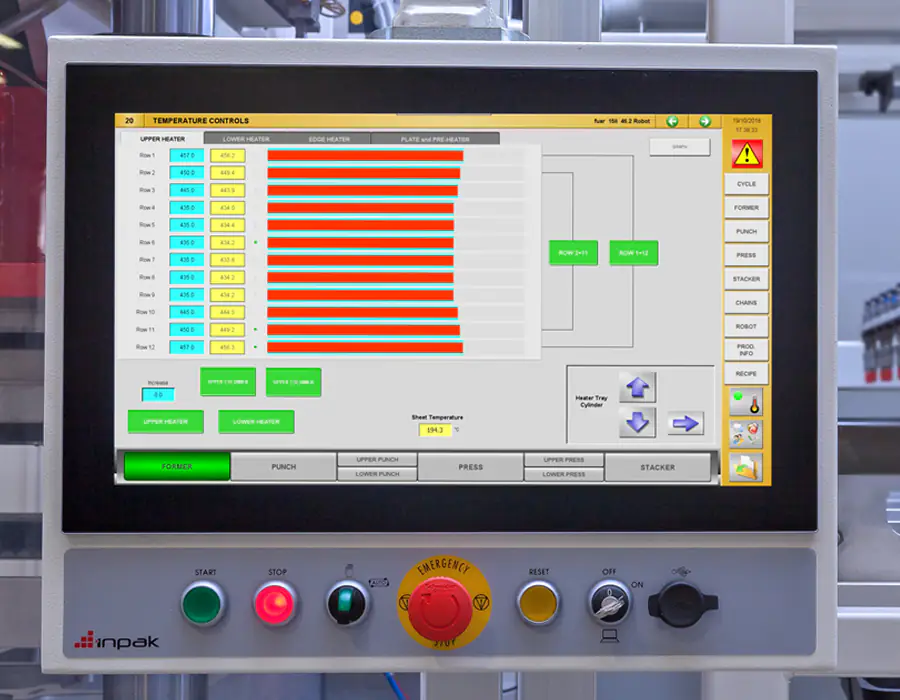

Key Features of a Thermoforming Machine

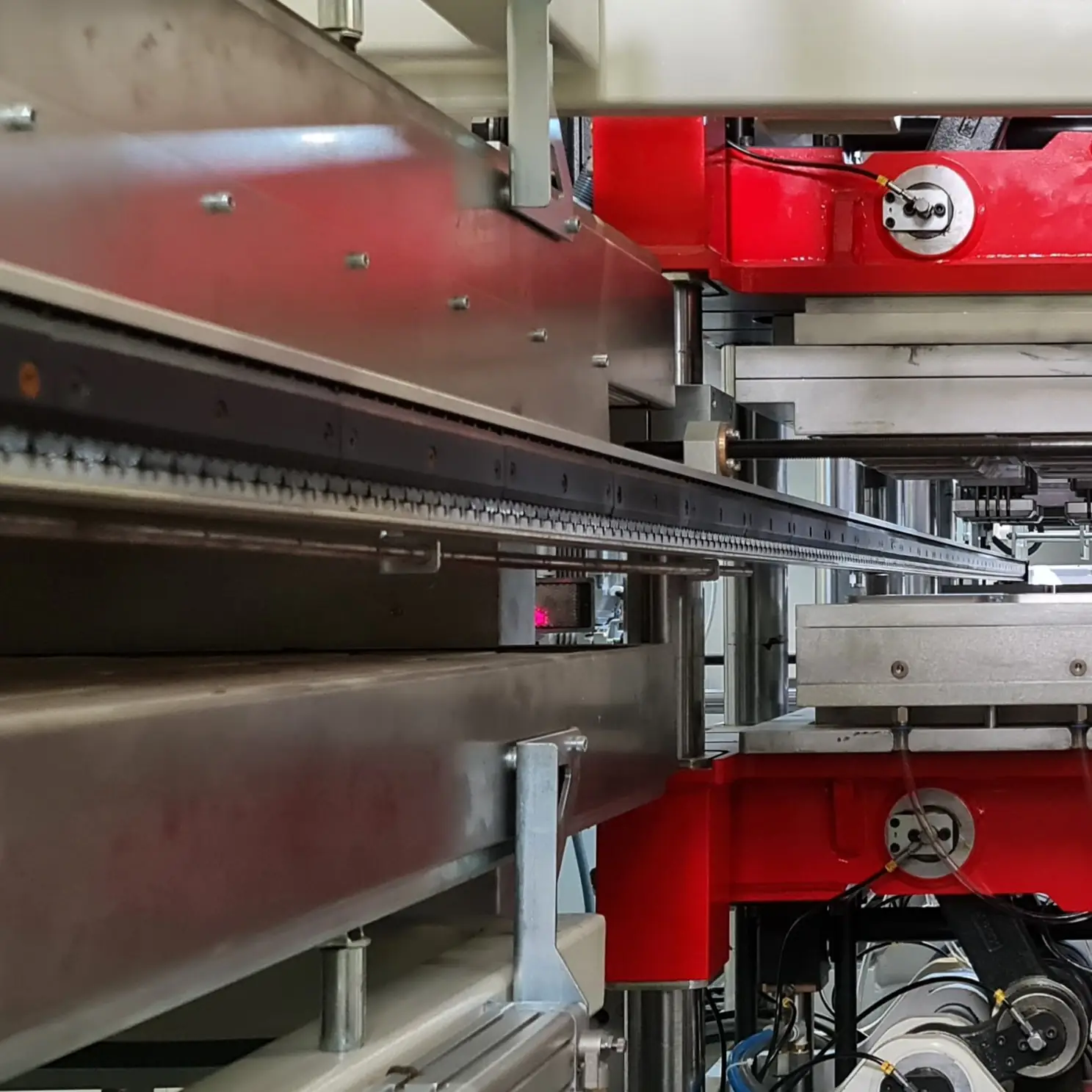

1. High-Performance Packaging Solutions

Thermoforming machines are engineered to produce durable and precise thermoforming packaging. From thermoforming machine for food packaging to custom thermoformed trays, these machines are perfect for businesses requiring advanced solutions for their products.

2. Compatibility with Multiple Materials

Supporting materials like PET, CPET, PP, PVC, PS, OPS, and PLA, thermoforming machines ensure flexibility in production while maintaining eco-friendly standards. This makes them an excellent choice for companies focused on sustainability.

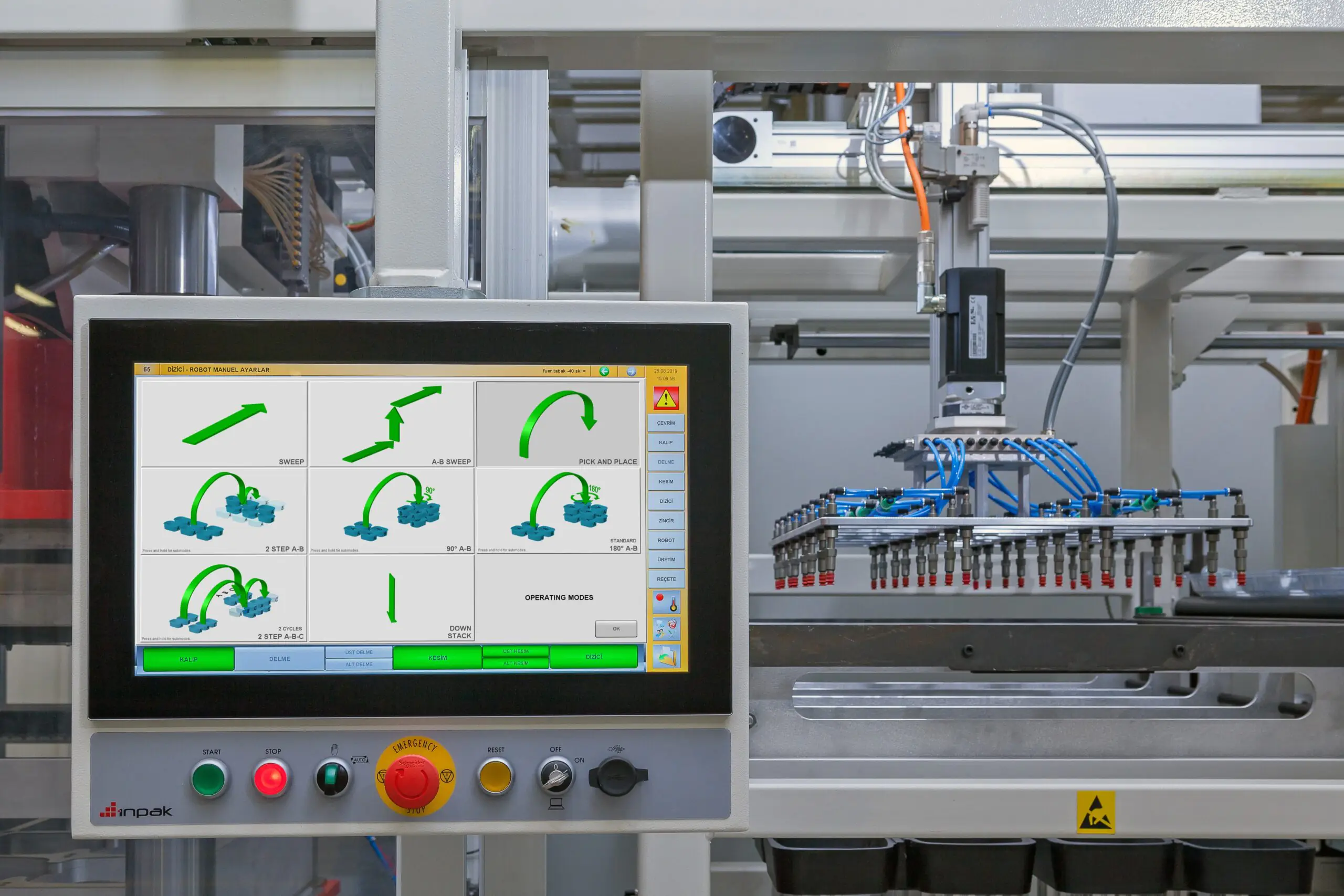

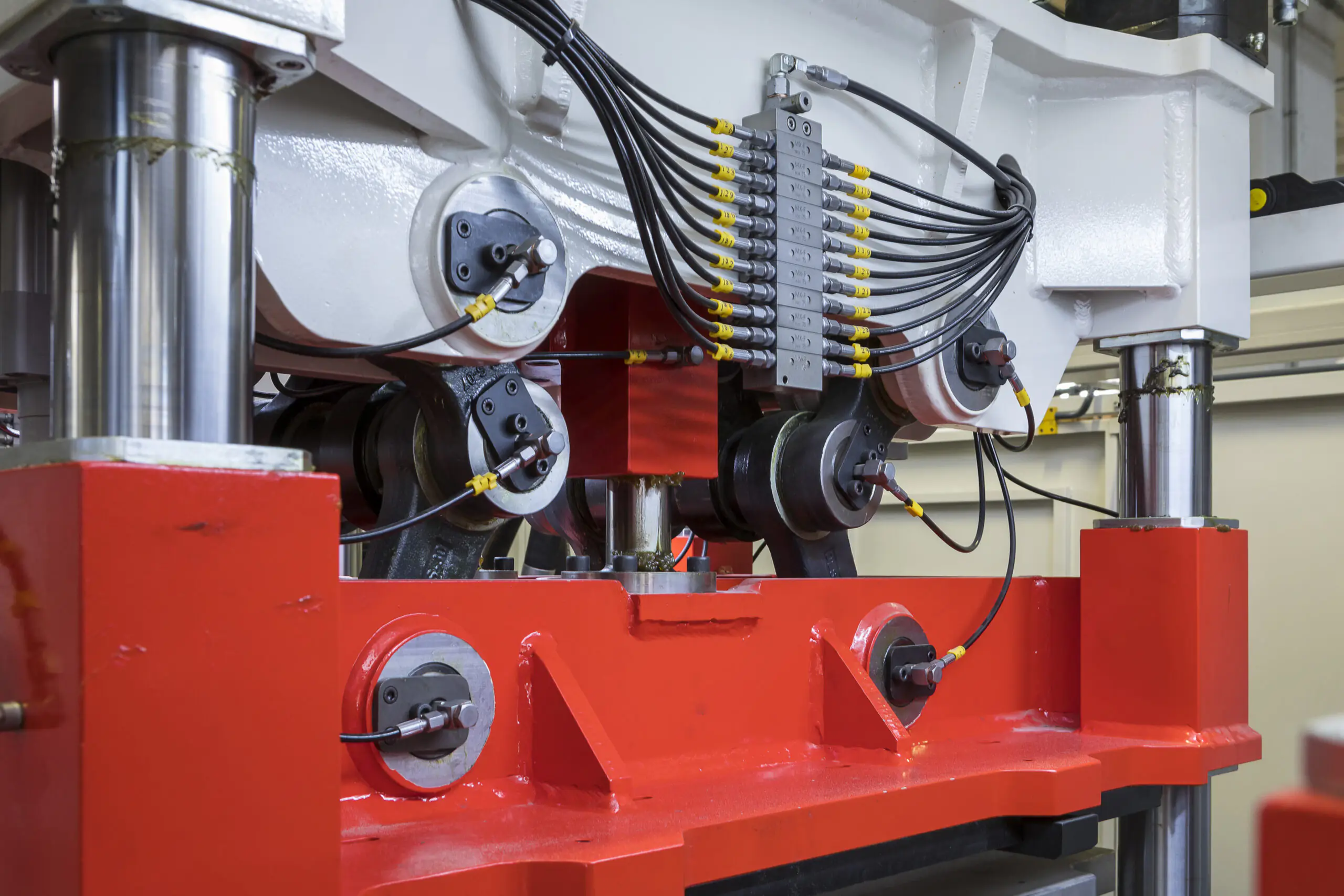

3. Integration of Vacuum Technology

Many thermoforming machines also function as vacuum forming machines, combining vacuum technology to enhance molding precision. For businesses seeking cost efficiency, vacuum forming machine price options provide affordability without compromising quality.

Applications of Thermoforming Machines in Food Packaging

1. Food Packaging Machines

Thermoforming machines are widely used in the food industry to create thermoformed food packaging solutions. They ensure hygiene, durability, and aesthetic appeal for food storage and transportation.

2. Packaging Thermoforming for Consumer Goods

Whether it’s trays, containers, or customized packaging, thermoforming machines enable manufacturers to deliver consistent results while maintaining high-quality standards.

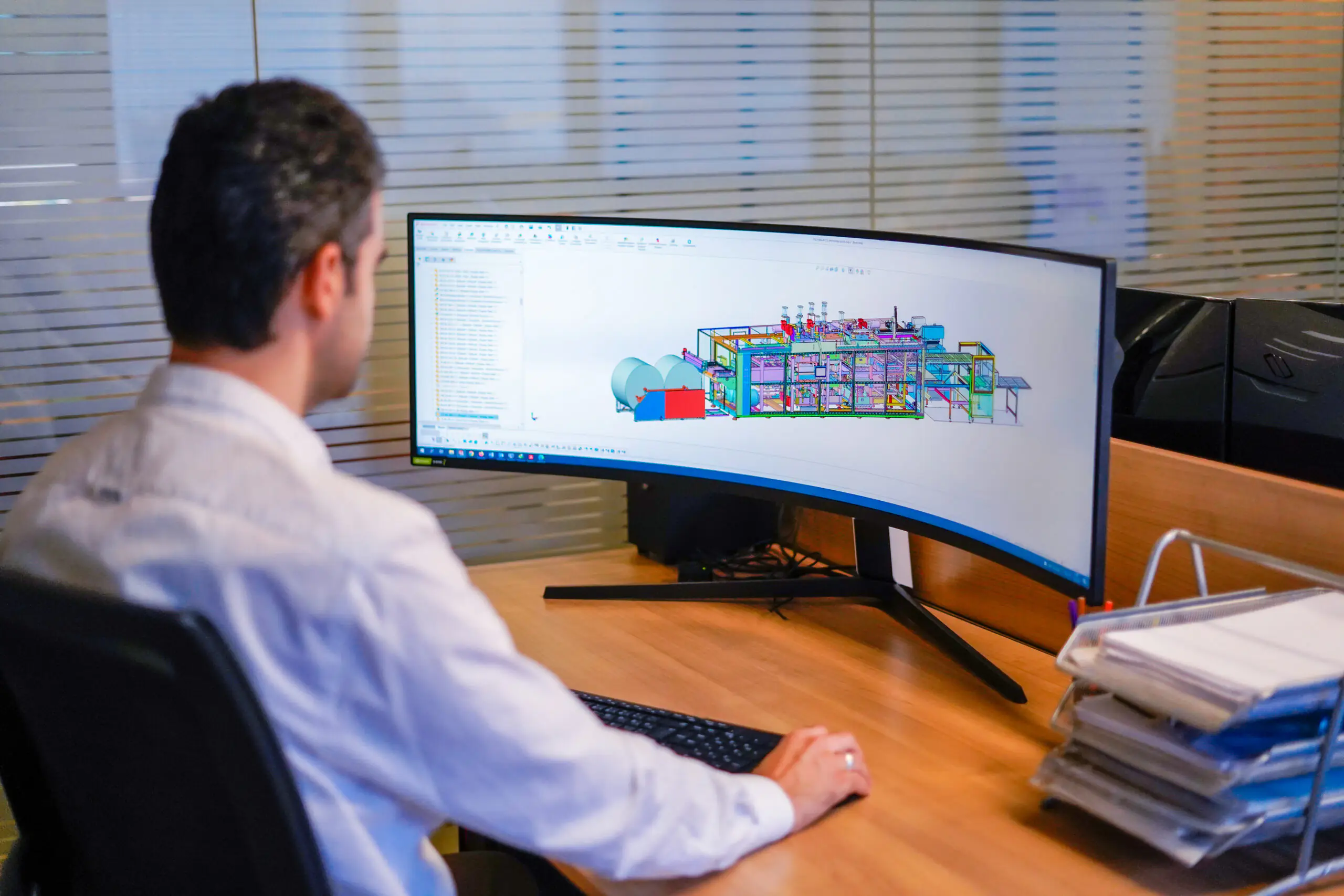

Thermoforming Machines by INPAK

At INPAK, we specialize in manufacturing top-of-the-line thermoforming machines for diverse applications. Our machines are designed to offer exceptional performance, including:

- Thermoforming Packaging Machine: Delivers high-speed, precise packaging solutions for industries like food and medical sectors.

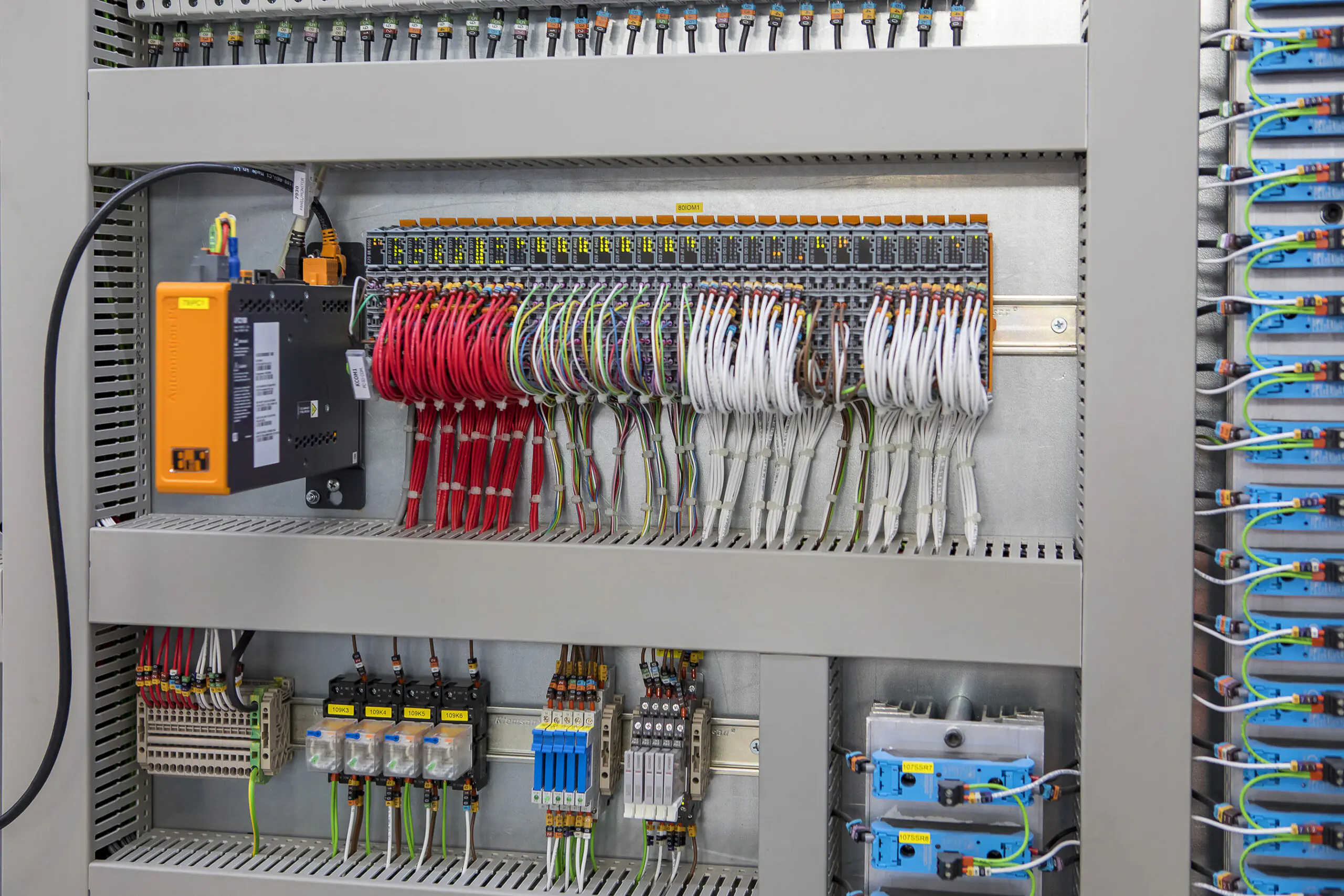

- Thermoformer: Engineered for advanced automation, ensuring consistent production cycles.

- Vacuum Forming Machine: Incorporates innovative vacuum technology for enhanced precision.

How Thermoforming Machines Enhance Productivity

- Increased Efficiency: Faster production cycles help businesses meet high-volume demands.

- Cost Savings: Reduced energy consumption and labor costs improve overall profitability.

- Custom Solutions: Tailored packaging options enable businesses to cater to specific customer needs.

Choosing the Right Thermoforming Machine

When selecting a thermoforming machine, consider factors like vacuum forming machine price, production capacity, and material compatibility. Whether you need a machine for food packaging or industrial applications, INPAK offers a range of solutions tailored to your requirements.

Conclusion: Elevate Your Packaging Process with INPAK Thermoforming Machines

INPAK’s thermoforming machines are the ideal solution for businesses looking to revolutionize their packaging processes. With advanced features, energy efficiency, and robust performance, our machines cater to diverse industries, from food packaging to custom thermoforming needs.

Contact INPAK today to discover how our machines can transform your production capabilities and set new standards in the thermoforming machine industry.