-

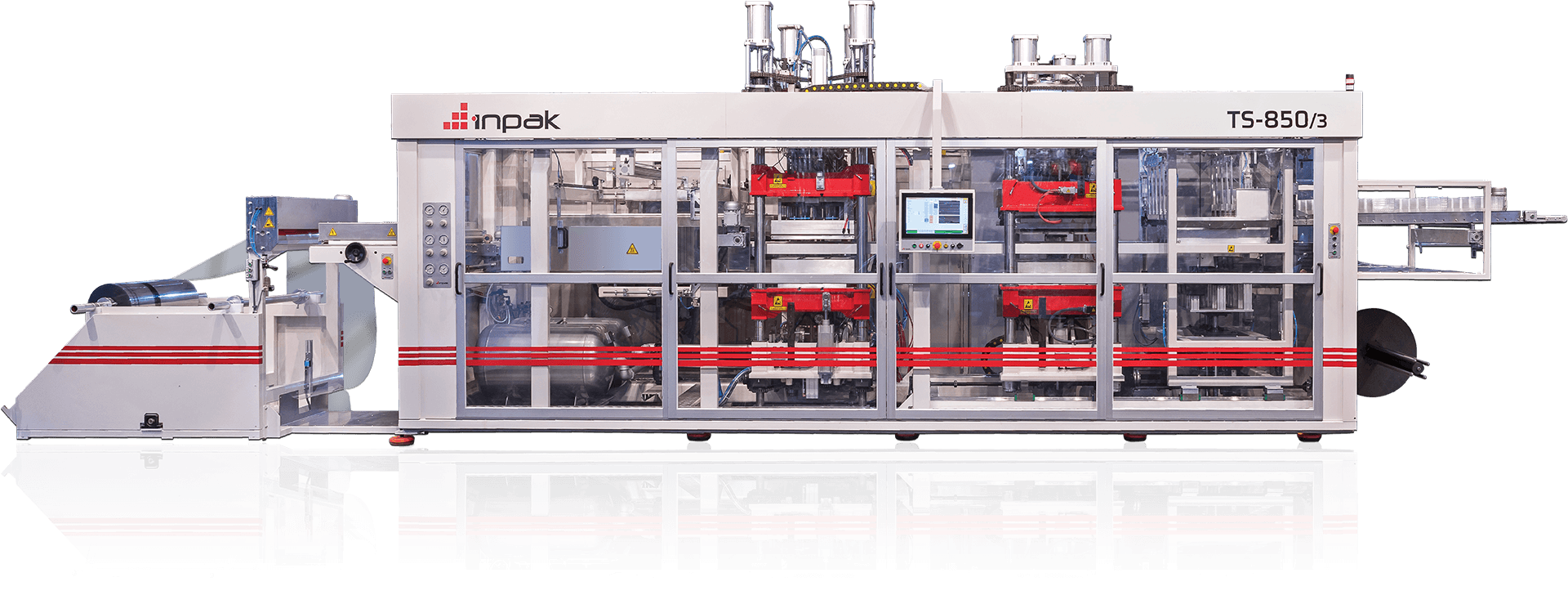

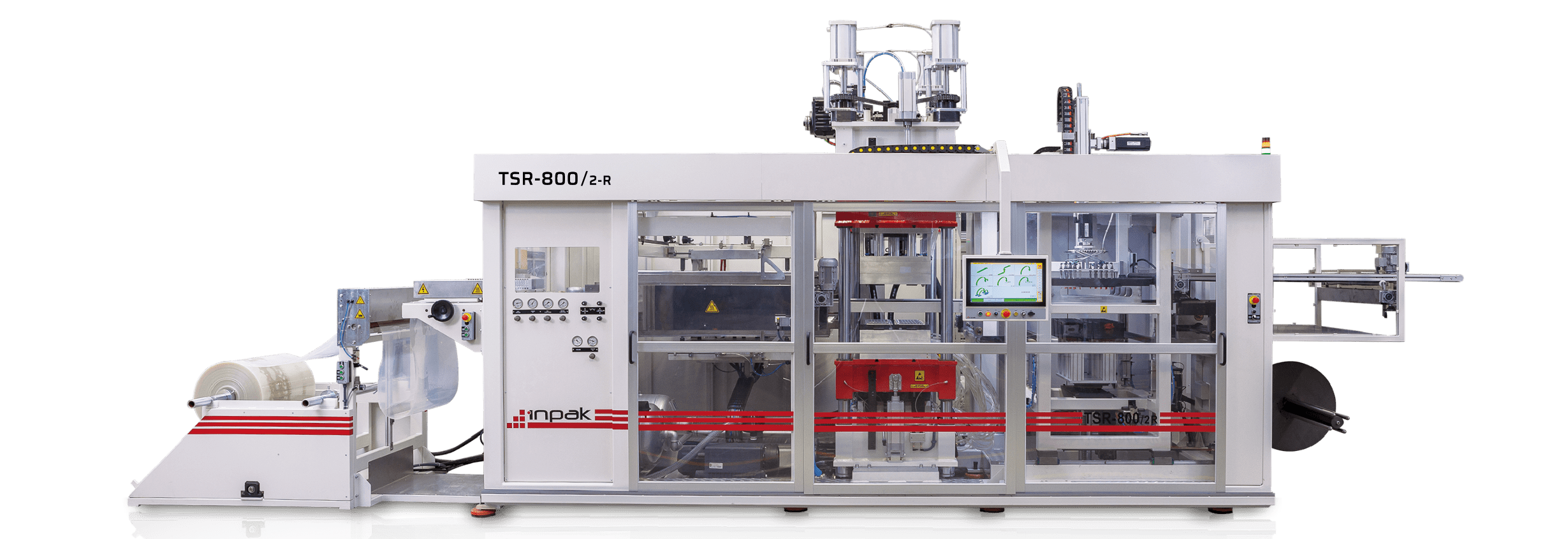

Unwinder

- Roll lifting system – Hydraulic

- Able to work with double roll

- Analog controlled, non- stop roll opener

- Max. roll diameter: 1200 mm

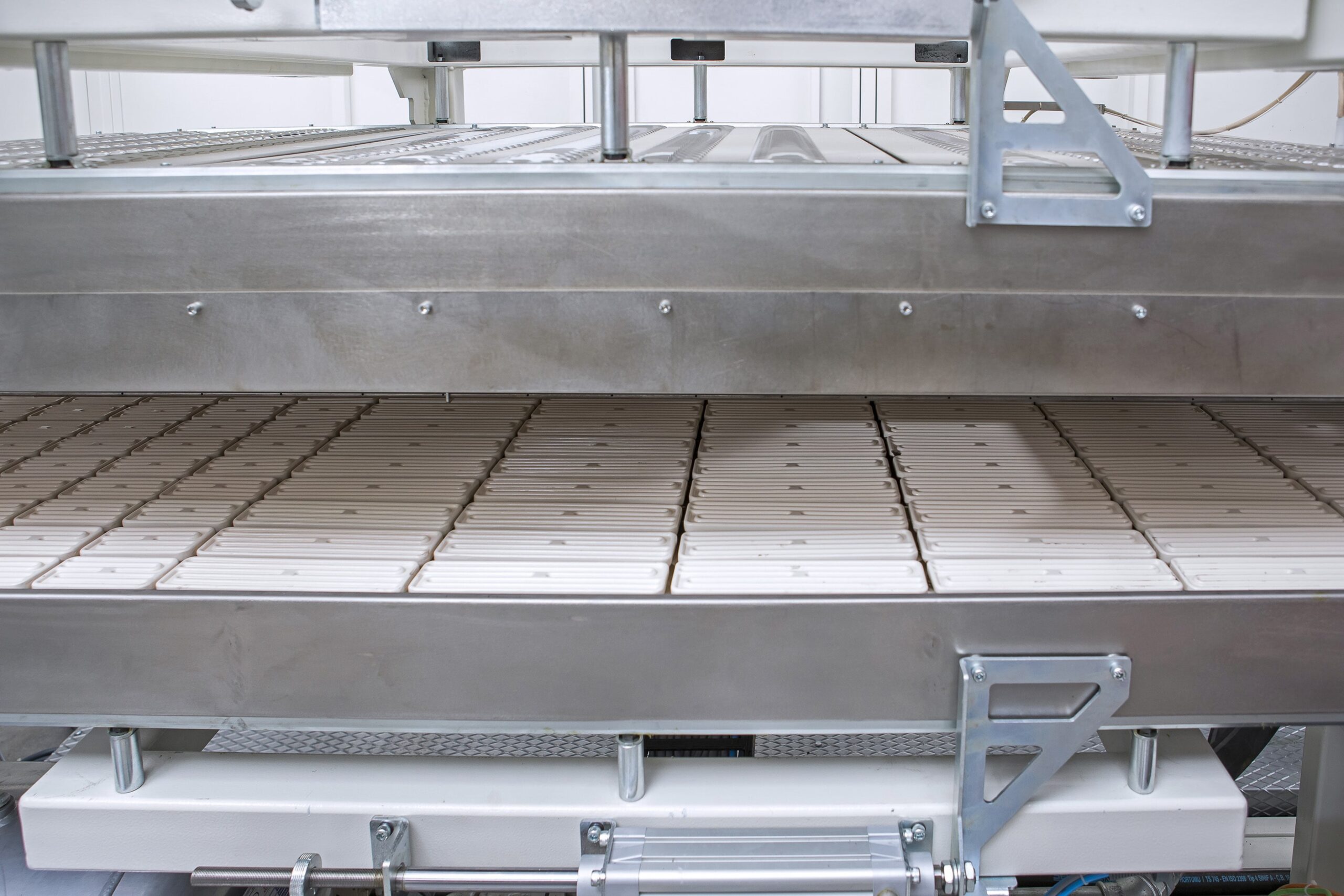

Chains and Rails

- Servo driven transport chains

- Sheet edge heaters (Quartz) at infeed

- JWIS chains

- Water cooled, aluminum profile chain rails

- Motorised rail distance adjustment from four points with rotary encoder for measurement

- Automatic sheet stretching system adjustable on the screen (Especially for PP sheet material)

- Automatic chain lubrication – (BEKA-MAX) PC controlled

- Photocell for pre-printed sheet

Heaters

- Upper heating power: 50 kW

- Lower heating power: 50 kW

- Elstein ceramic heaters in top and lower heater trays, individually adjustable (line by line), made from AISI-304 stainless steel – 12 rows – 2 x 50 = 100 kW

- Infrared temperature measurement on sheet surface

- Sensor control against sheet sagging

- Dimensions of trays: L 1760 mm x W 860 mm

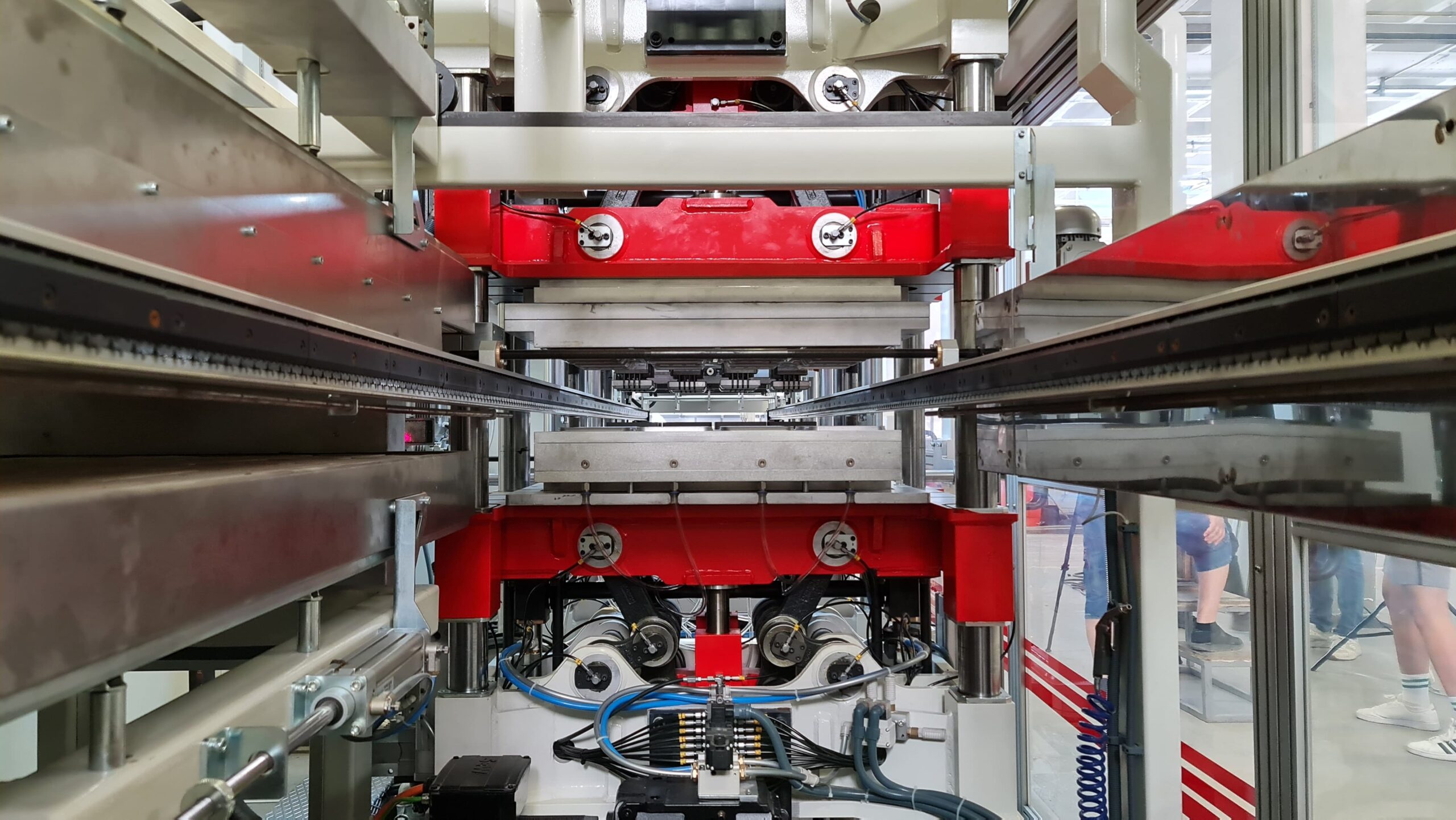

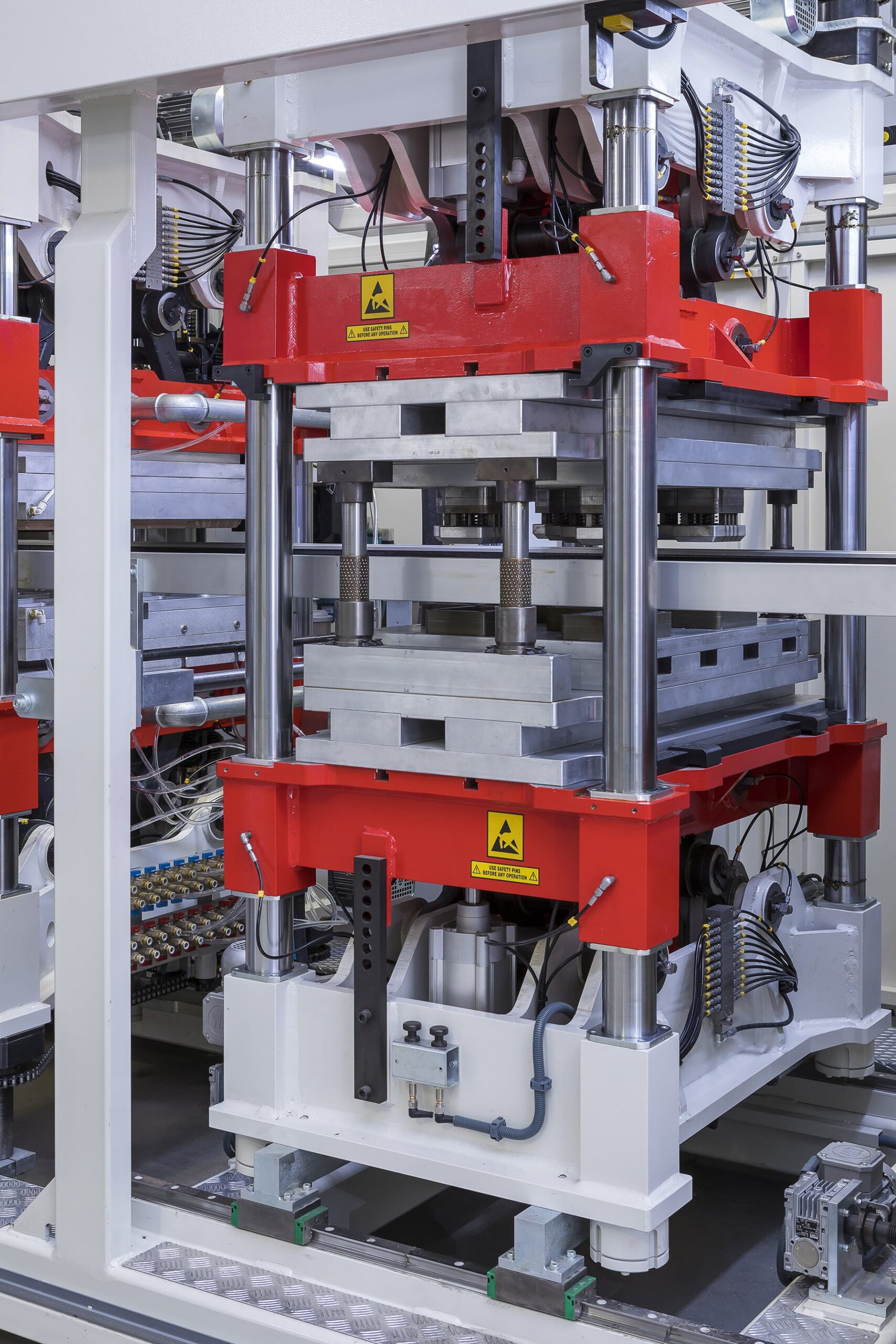

Forming Station (In-Mould Cutting)

- Upper forming depth: 140 mm

- Lower forming depth: 140 mm

- 4 Column – Servo motor driven, clamping force: 800 kN

- Max. mould size: 800 x 580 mm

- Max. stroke (Upper/ Lower): 150mm/ 150mm

- Servo driven plug assist on top forming station

- Forming by air pressure and or vacuum

- Clamp frame or plug assist with precise stroke adjustment on top and bottom former

- Motorised mould height adjustment on top forming station

- Pneumatic weight balancing system

- Long-life, special needle bearings, gapless joints

- Flow control sensor for cooling water

Hole Punching Station

- Platens Stroke (Upper/ Lower): 150mm/ 150mm

- Servo motor driven, top and bottom independent – Punching force: 500 kN

- Motorised position adjustment of station with rotary encoder

- Pneumatic weight balancing system

- Long-life, special needle bearings, gapless joints

- Motorised vertical adjustment of top table

- Vacuum device for hole punching scraps

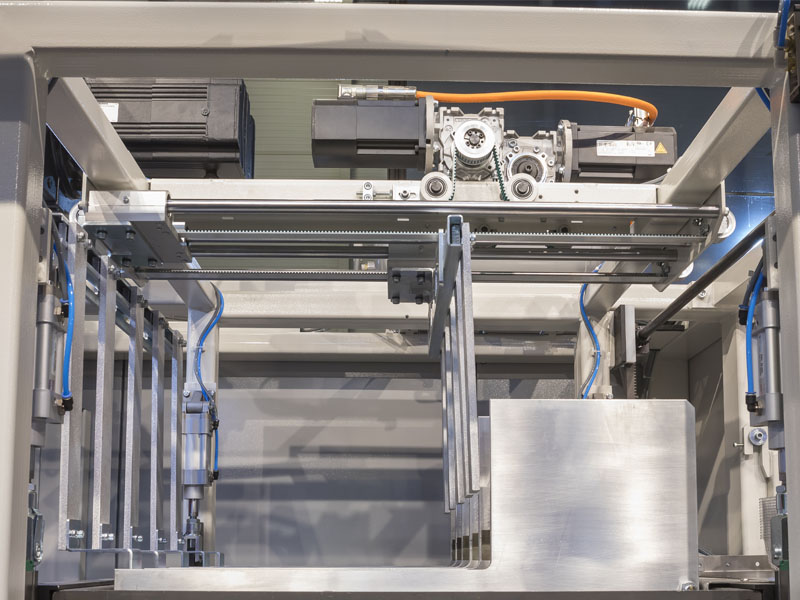

Cutting Station

- Platens stroke (Upper/ Lower): 150mm/ 150mm

- Power of plate heaters: 9 kW

- Servo motor driven, top and bottom independent clamping force: 600 kN

- Cutting knife heating (max. 170°C) and isolation plate

- Motorised X-Y adjustment system with measurement by rotary encoder

- Motorised position adjustment of station with rotary encoder

- Motorised precision cutting adjustment on top table by 0,03mm/pulse

- Tool fixing system with electrical safety interlocks

- Pneumatically weight balancing system

- Long-life, special needle bearings, gapless joints

- System for taking up the play between the adjusting nuts and shafts when machine comes under load.

Sweeper

Sweeping the stacked and counted products from the stacker upper frame walls towards the conveyor.

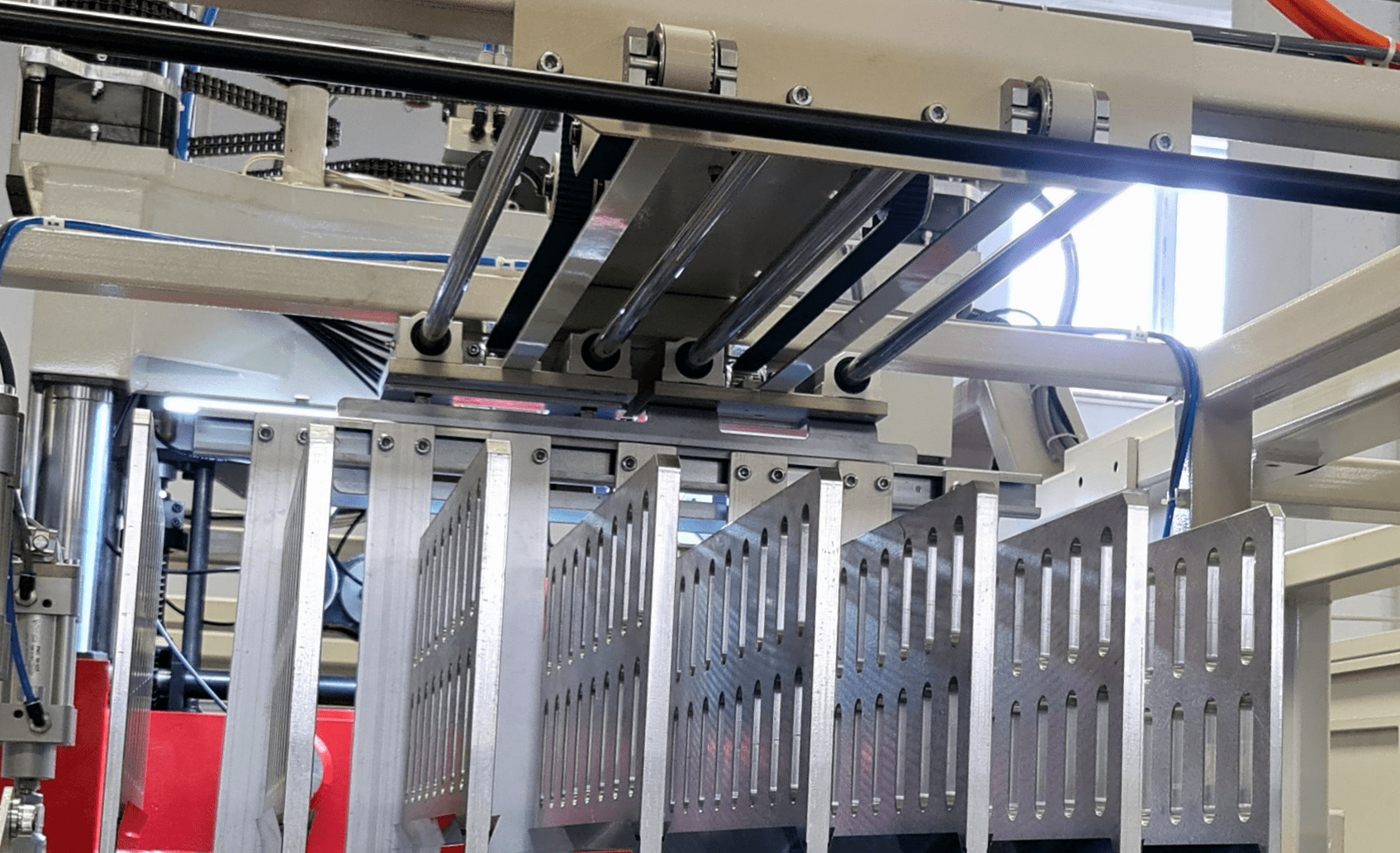

Servodriven A-B Stacker & Sweeper

Alternative of the robot stacker for A-B or A-B-C stacking. It enables you having AB stacking inside the upstacker frame walls. “A” product line goes under “B” line with a servo motor driven mechanism. Another servomotor drives the counted stacked products on to the conveyor. A-B or A-B-C stacking is possible with actual forming speeds.

eds.

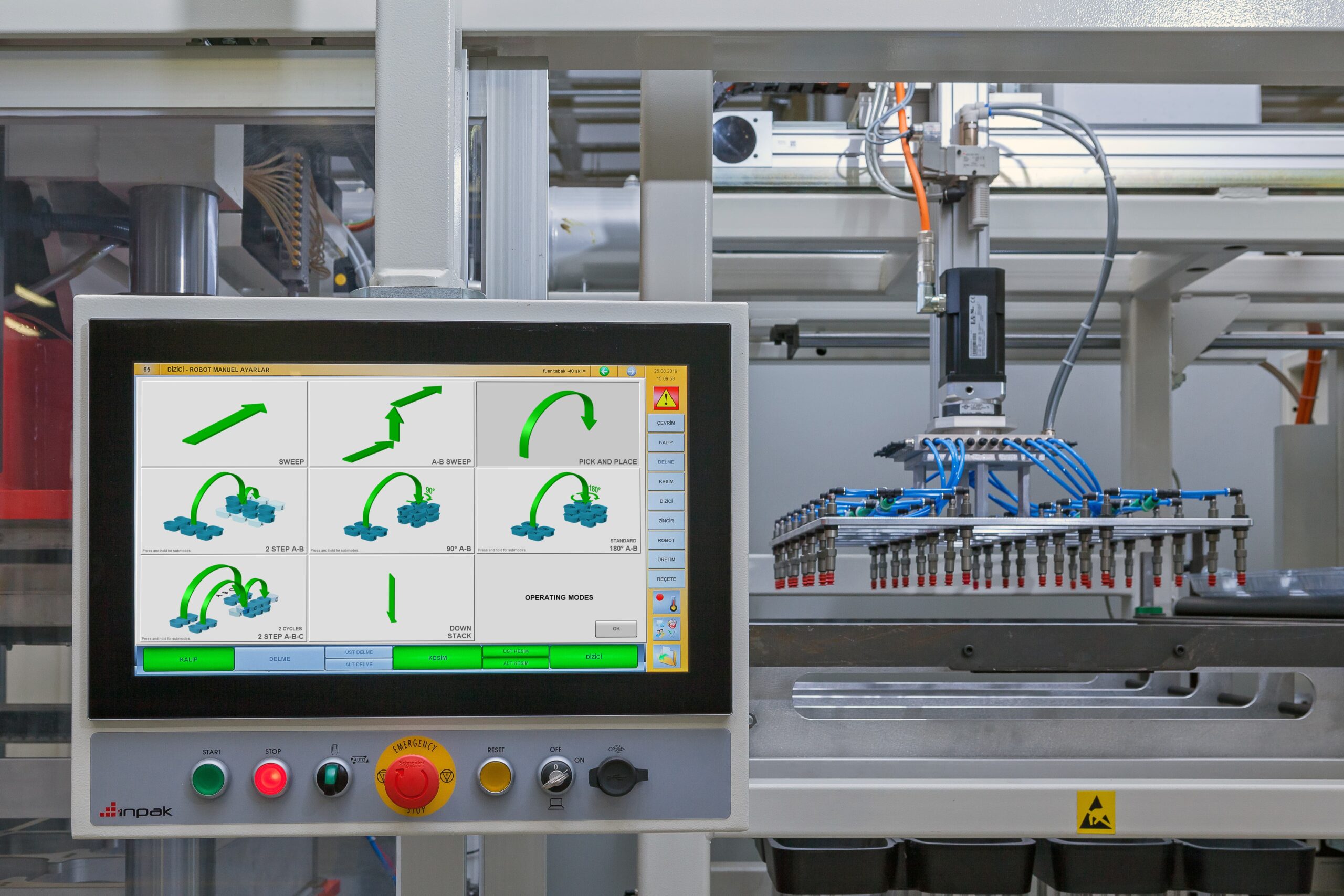

Robot Stacker

Robot stacker is the most flexible option which provides several working modes. This is a good option for A-B stacking, also good for short or small products which are difficult to held in conventional stacker upper frame walls.

Classic working modes:

- Classic sweeper mode

- Classic A-B stacking mode (A-B within upstacker frame walls)

Robot working modes:

- Pick and place

- 180° A-B stacking

- 90° A-B stacking

- 2-step A-B stacking

- A-B-C stacking

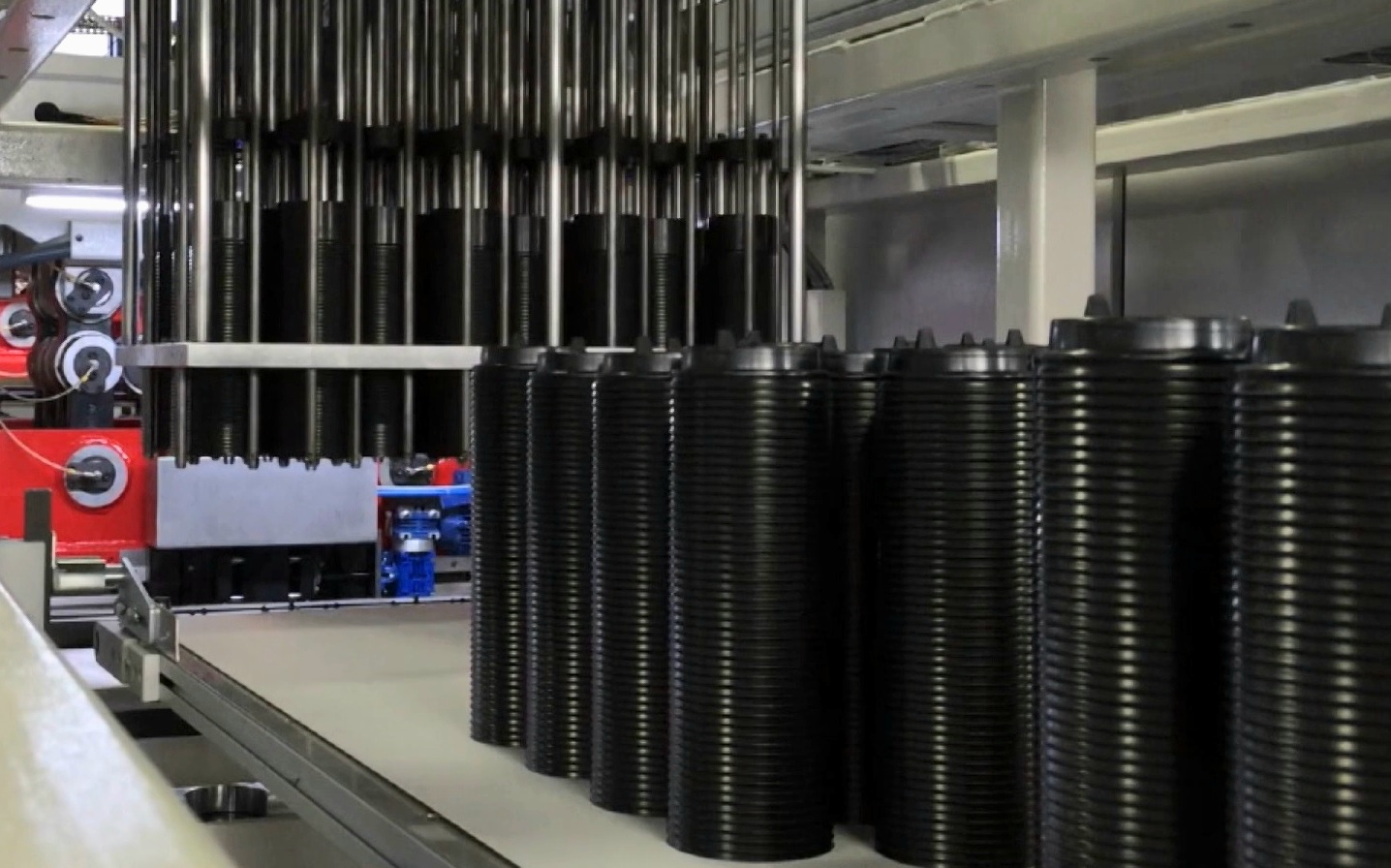

Lid Robot Stacker

(with Servodriven Upper and Lower Frame)

Lid robot stacker has advantages and it is useful when most of the dedicated products for the machine has round cutting geometries. The system enables having higher stacks. It is also possible to have reduced sheet scrap ratios with “W” cavity placements.

Working modes:

- Classic sweeper mode

- Classic A-B stacking mode (A-B within upstacker frame walls)

- Round shaped product stacking with lid robot system

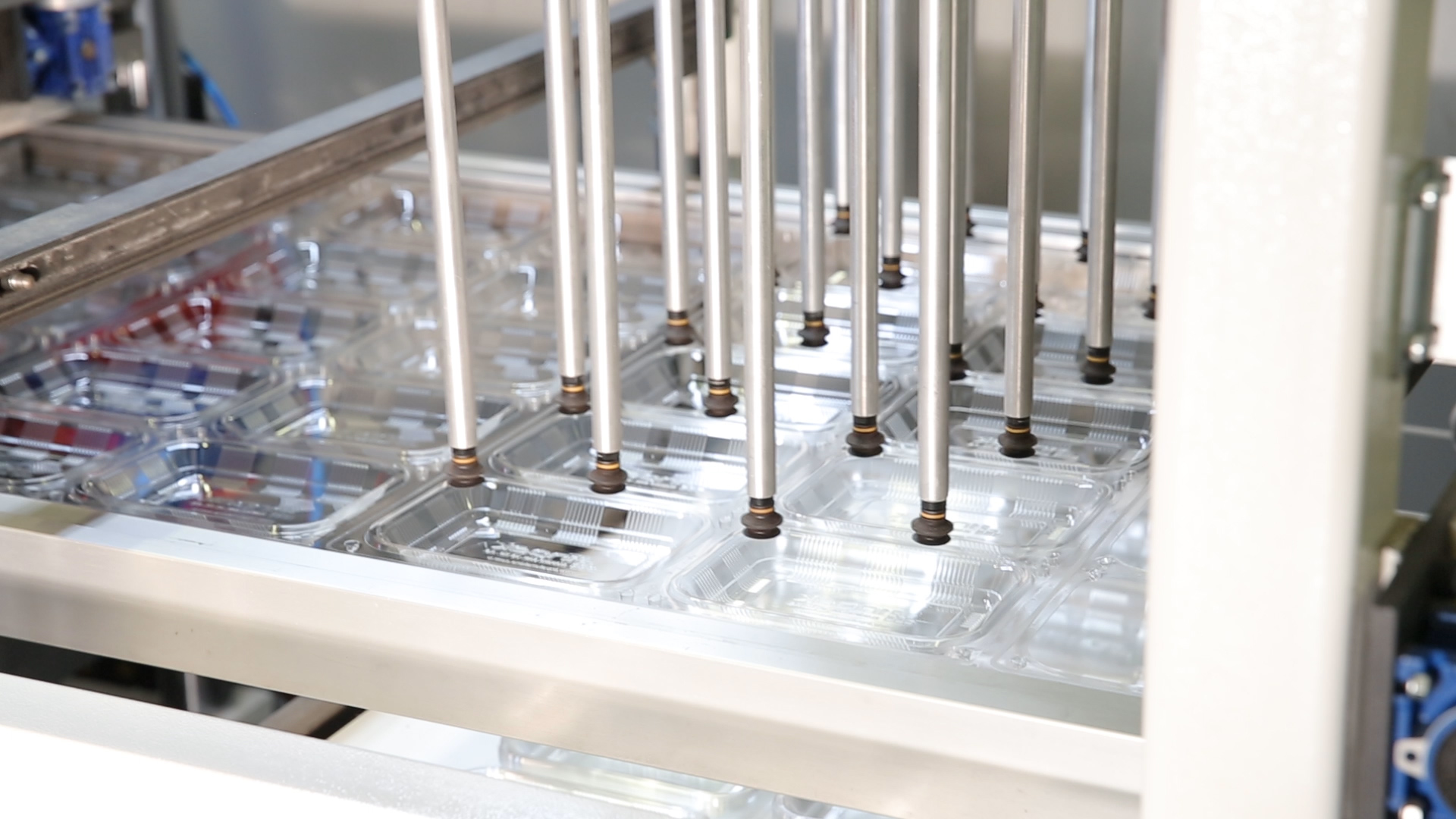

Down Stacker

Down stacker is an additional feature to standard upward stacking. Down stacker is useful while stacking large and thin products such as fruit liner trays. Such products are not easy to be held in upstacker frame walls. Therefore, down stacker is well suited for these type of products.

Scrap Winder

- Asynchronous winder motor with electronic torque control

- Pneumatic discharging system of scrap

Electrical Unit

- Electrical cabinet and installation to CE standard.

- High quality electrical and electronic components (SEW, B&R, SIEMENS, MOELLER, OMRON, SCHNEIDER)

- Air-conditioner for cabinet

Longer Lifetimes

Highest Cycle Speeds

Less Energy Consumption

Ease of Use