High-Quality Thermoforming Products for Modern Manufacturing

In the world of modern manufacturing, thermoforming products have gained significant popularity for their versatility, efficiency, and ability to meet the demands of various industries. These products are typically made by heating a thermoplastic sheet until it becomes pliable, then shaping it into a mold to create an array of items such as packaging, trays, and containers. Thermoforming products are essential in the production of durable and cost-effective packaging, including solutions for food, medical, and industrial sectors. Due to the advanced technology behind thermoforming, these products are designed to meet rigorous standards while promoting sustainability and reducing waste in manufacturing processes.

Table of Contents

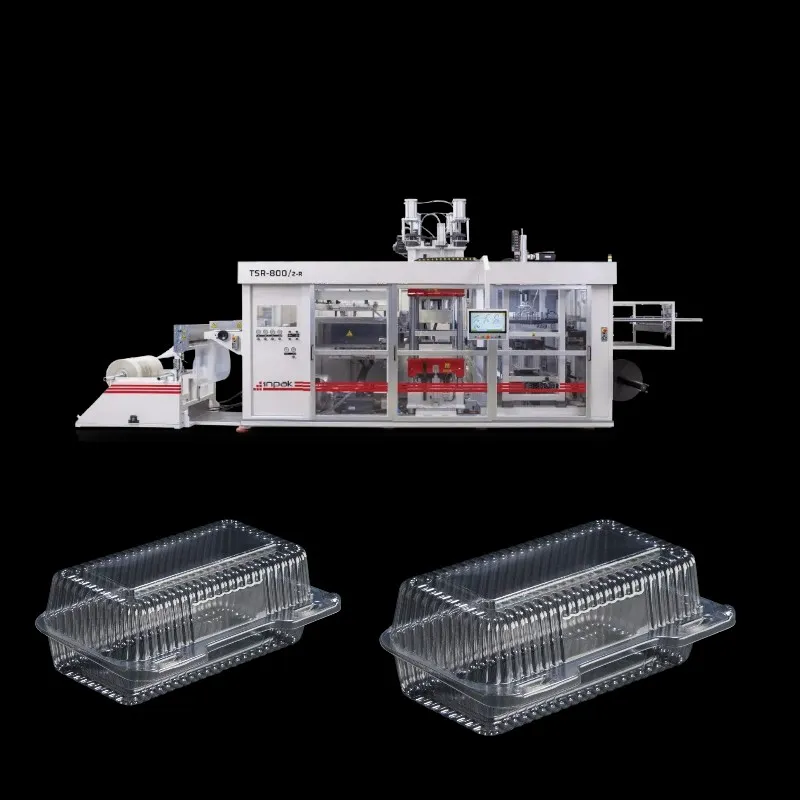

One of the primary factors that make thermoforming products ideal for modern manufacturing is their customizability. Manufacturers can easily design packaging products to fit specific shapes, sizes, and functions, providing businesses with tailored solutions for their packaging needs. Thermoforming machine for thermoform packaging products is commonly used in the food industry to create high-quality food containers and trays that meet hygiene and aesthetic standards. Additionally, the versatility of thermoforming products allows them to be used in a variety of industries such as medical packaging, where sterilization and durability are paramount, as well as consumer goods and electronics packaging.

The efficiency and speed of production are another key advantage of thermoforming products. Thermoforming machines are engineered to produce large quantities of molded plastic products at a rapid pace, offering businesses an edge in highly competitive markets. With advanced systems in place, such as thermoforming machines for molded plastic products, companies can achieve consistent, high-quality results while meeting production deadlines. This makes thermoforming an attractive option for industries looking to balance speed with quality, while also reducing operational costs.

What are Thermoforming Products?

Thermoforming products refer to a wide range of items made through the thermoforming process, where a plastic sheet is heated to a specific temperature, softened, and then molded into a desired shape using pressure or vacuum. These products are highly efficient and can be used for various applications in food, medical, industrial, and consumer goods packaging. The process allows manufacturers to create complex shapes and designs with precision, making it a popular method for producing packaging that needs to be both functional and visually appealing. For example, food packaging machines use thermoforming machines to produce trays, clamshells, and other types of food containers.

Thermoforming products can be made from a variety of thermoplastic materials, including PET, CPET, PP, PVC, PS, OPS, and PLA, each of which has distinct properties suitable for specific applications. Thermoforming machine manufacturers offer custom solutions based on material compatibility, ensuring that the final product meets industry standards for durability, strength, and sustainability. For businesses in the food industry, thermoforming machine for plastic thermoformed products ensures the production of safe and hygienic packaging solutions that are essential for preserving the freshness of food.

In addition to the variety of materials available, thermoforming products can be designed to accommodate different production needs. For instance, thermoforming machines for molded plastic products are built to handle high-volume production, making them ideal for businesses that require large quantities of consistent packaging. Whether for food packaging machines, plastic packaging machines, or other industries, the ability to tailor products to meet specific demands makes thermoforming a highly valuable technology in modern manufacturing.

INPAK – High-Quality Thermoforming Products for Modern Manufacturing

Types of Thermoforming Products

There is a wide range of thermoforming products, each designed to meet the specific requirements of different industries. The most common types include food packaging, medical packaging, and industrial packaging. Thermoforming machine for thermoform packaging products is often used in the food industry to create trays, containers, and other packaging materials that ensure food safety, quality, and ease of handling. These products can be made from eco-friendly materials, such as PLA, which supports businesses’ sustainability goals while ensuring high-performance standards.

Another significant category of thermoforming products is medical packaging, where the need for precision, sterilization, and durability is critical. Thermoforming machine for molded plastic products is widely used to produce sterile trays, containers, and blister packs for medical devices and pharmaceuticals. This type of packaging helps maintain the integrity of medical products, ensuring they remain protected during storage and transportation while also complying with industry regulations for cleanliness and safety.

In industrial applications, thermoforming products are used to create durable, protective packaging for electronic components, automotive parts, and machinery. Thermoforming machine for plastic thermoformed products can be used to create custom containers that are robust and resilient to damage, protecting goods during shipping and handling. The ability to produce custom solutions for specific packaging needs makes thermoforming a popular choice for industries requiring high-performance and long-lasting materials.

INPAK – High-Quality Thermoforming Products for Modern Manufacturing

The Development of Thermoforming Technology and Modern Applications

The development of thermoforming technology has led to significant advancements in the manufacturing of packaging products. Modern thermoforming machines are now equipped with advanced features that enhance the precision, speed, and flexibility of production. Thermoforming machine manufacturers have integrated cutting-edge technologies, such as servo motors and automated controls, to ensure greater accuracy in molding and faster production cycles. This evolution in machine design has allowed businesses to create complex packaging products that were once considered difficult to produce.

The demand for sustainable packaging solutions has also driven innovation in thermoforming technology. Thermoforming machines for molded plastic products are now designed to use eco-friendly materials such as PLA and recyclable PET, ensuring that packaging solutions meet the growing emphasis on environmental responsibility. Modern thermoforming machines also enable manufacturers to produce products with less material waste, which contributes to reducing costs and promoting sustainability in manufacturing.

In addition to sustainability, the increased demand for custom packaging solutions has encouraged the development of highly adaptable thermoforming machines. These machines can be fine-tuned to accommodate specific material types and molding techniques, allowing businesses to offer a diverse range of packaging products. Whether it’s food packaging machines or custom plastic packaging solutions, the ability to produce tailored, high-quality products with fewer resources is one of the key benefits of modern thermoforming technology.

INPAK – High-Quality Thermoforming Products for Modern Manufacturing

Thermoforming Machine Solutions for Industrial Needs

For industries with specific packaging needs, thermoforming machine solutions provide the versatility required to produce high-quality products at scale. Thermoforming machines for plastic thermoformed products allow manufacturers to create a broad range of packaging items, from simple containers to more complex, custom shapes. These machines are designed to handle various thermoplastic materials, offering flexibility in production and ensuring that businesses can meet diverse market demands. The adaptability of these machines makes them an ideal choice for industries such as food, medical, and industrial packaging.

One of the key advantages of thermoforming machine solutions is their efficiency. With the ability to produce large quantities of products quickly, these machines help companies keep up with high demand while maintaining quality. For businesses in the food industry, for example, food packaging machines equipped with advanced thermoforming technology can produce consistent, high-quality packaging in a fraction of the time compared to traditional methods. This boosts productivity and allows businesses to streamline their operations while reducing costs.

Additionally, thermoforming machine manufacturers now offer machines equipped with enhanced automation features, such as automatic lubrication systems and sensitive positioning technology, which ensures precise molding and reduces downtime. For industries that require rapid and accurate production, these features help optimize manufacturing processes and improve overall productivity. As industries continue to demand higher performance and cost-effective solutions, thermoforming machine solutions are essential for businesses to stay competitive in the evolving market.

INPAK – High-Quality Thermoforming Products for Modern Manufacturing

Efficiency and Cost-Effectiveness: Manufacturing with Thermoforming

One of the biggest advantages of using thermoforming machines is their efficiency in manufacturing. Thermoforming products can be produced quickly and with minimal material waste, making the process highly cost-effective. By utilizing thermoforming machine for molded plastic products, manufacturers can reduce production costs and enhance overall profitability. Furthermore, thermoforming machines often require less energy to operate compared to other manufacturing processes, such as injection molding, which adds to their cost-effectiveness.

The ability to produce high volumes of products with minimal waste contributes to both cost savings and sustainability. By using eco-friendly materials such as PLA and optimizing production techniques, thermoforming machines help manufacturers reduce their environmental impact while still achieving excellent production results. In industries such as food packaging and medical packaging, where hygiene and precision are critical, the ability to produce high-quality packaging solutions efficiently is a key benefit.

In addition to their cost-effectiveness, thermoforming machines are highly customizable, allowing manufacturers to meet the specific needs of their clients. Whether it’s producing custom shapes for consumer goods packaging or producing large quantities of packaging for the food industry, thermoforming machine for thermoform packaging products ensures that businesses can deliver tailored solutions while optimizing production costs.

INPAK Thermoforming Machine Solutions for Efficient Production

At INPAK, we specialize in providing advanced thermoforming machine solutions designed to optimize production and enhance efficiency. Our machines are engineered to meet the needs of diverse industries, offering custom solutions for businesses looking to produce high-quality packaging. Whether you’re in the food, medical, or industrial sectors, INPAK’s thermoforming machines can help streamline your production process while maintaining the highest standards of quality and sustainability.

Our thermoforming machine solutions are designed for both high-volume and custom applications. With advanced features such as remote access, automatic lubrication systems, and precise heating configurations, INPAK machines ensure that your production process is efficient, cost-effective, and reliable. As thermoforming machine manufacturers, we are committed to providing the latest technology to meet the evolving needs of the packaging industry.

By choosing INPAK, businesses can access superior thermoforming machine solutions that not only enhance production efficiency but also provide long-lasting performance. Our machines are built with durability in mind, ensuring that your business can produce high-quality products for years to come. Contact INPAK today to discover how our thermoforming machines can elevate your packaging process and help you stay competitive in the ever-changing market.