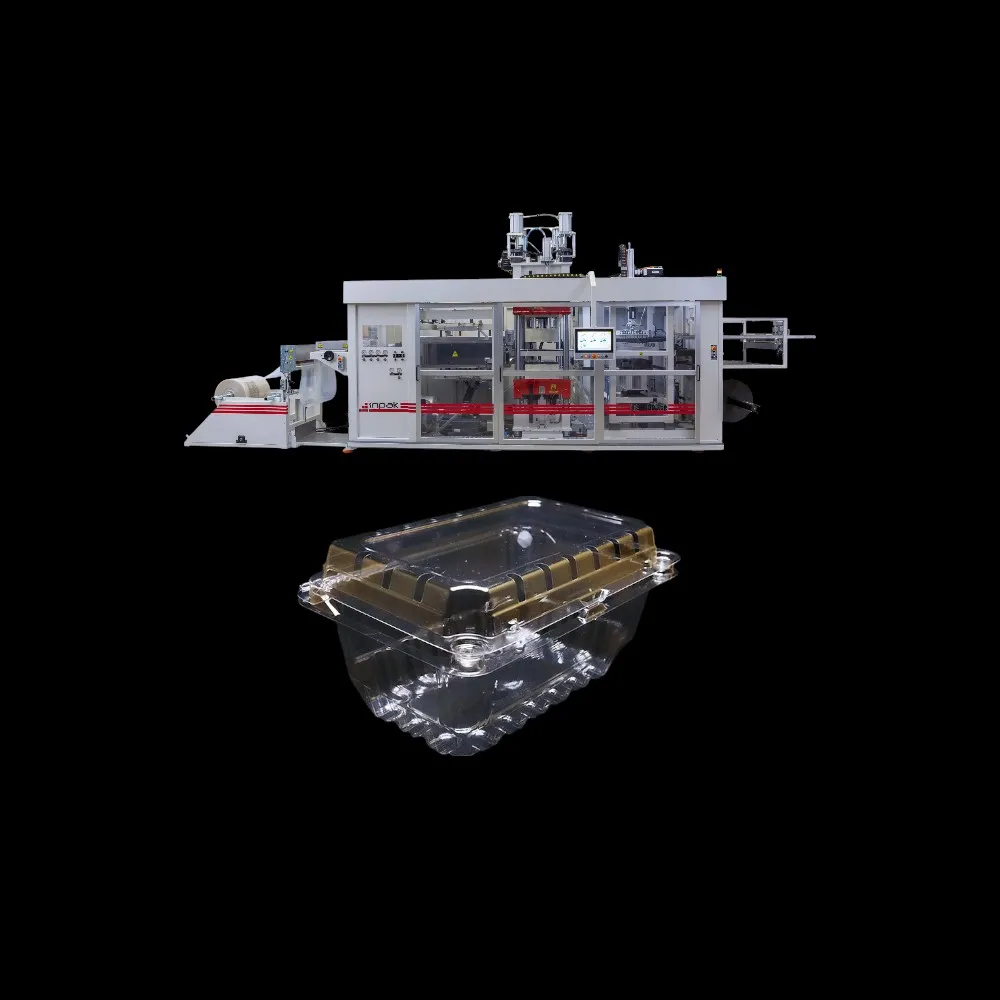

Thermoforming Machines for Heated Plastic Food Containers

Thermoforming machines have revolutionized the production of heated plastic food containers, offering precision and efficiency for manufacturers. These machines provide a versatile and scalable solution for producing containers that can withstand high temperatures, essential for the food industry. By using heat and pressure to form plastic sheets into desired shapes, thermoforming machines enable the production of a wide range of containers that meet specific requirements, such as microwave safety and heat resistance.

Table of Contents

The ability of thermoforming machines to produce heated plastic food containers is a critical advancement for food packaging. These machines are designed to handle specialized materials that maintain their integrity under high temperatures, making them ideal for ready-to-eat meals and takeout packaging. With growing consumer demand for convenience and sustainability, plastic packaging machines must also meet high standards for safety and durability, ensuring that food products are well-protected during heating, storage, and transport.

For businesses looking to optimize their food packaging processes, selecting the right thermoforming equipment is essential. Thermoforming machines offer numerous advantages, including high-speed production, reduced material waste, and customization options that cater to diverse packaging needs. As thermoforming machine manufacturers continue to innovate, these machines are becoming more energy-efficient and capable of producing eco-friendly packaging solutions, aligning with industry trends and consumer expectations.

What Is a Heatable Plastic Food Container?

A heatable plastic food container is a type of packaging specifically designed to safely transport and store hot or heatable food products. These containers are typically made from plastics that can be used in microwave ovens, allowing food to retain its temperature and be presented to consumers without compromising quality. Heatable plastic food containers play an important role in the food transportation process by maintaining the temperature and ensuring that food reaches the consumer without losing its quality. Additionally, they offer practical use that aligns with modern consumer habits.

These containers are particularly ideal for the ready-meal industry and restaurants. Meals can be easily heated, transported, and quickly served to consumers in these containers. Manufactured using a plastic packaging machine, these products are precisely shaped and provide the correct size for packaging. Food packaging machine manufacturers are increasingly turning to these technologies to provide optimal solutions for food temperature management

The Importance of Thermoforming in Heated Plastic Food Containers Production

Thermoforming technology is essential in the production of heated plastic food containers, ensuring that packaging materials can withstand extreme temperatures. The process of thermoforming enables manufacturers to shape plastic sheets into durable containers that maintain their structural integrity when exposed to heat. This is particularly crucial for food containers used in microwaving, oven-heating, or storing hot food products.

The versatility of thermoforming machines in producing heat-resistant containers has enabled the packaging industry to meet evolving demands for high-performance materials. Food packaging solutions must ensure food safety and quality while also providing convenience for consumers. Thermoforming technology helps achieve these goals by producing containers that are not only heat-resistant but also maintain their shape and strength under high temperatures, reducing the risk of contamination or spillage.

As food safety continues to be a priority, thermoforming technology offers a reliable solution for creating containers that meet both consumer and regulatory standards. Heated plastic food containers made with thermoforming machines are tested for their ability to withstand microwave heating and oven temperatures, making them ideal for a variety of food products. In addition, the ability to produce custom designs with specific heat resistance properties ensures that food packaging can be tailored to suit various customer preferences and product types.

Key Features of Advanced Thermoforming Machines for Heated Containers

Modern thermoforming machines come equipped with advanced features that enhance production efficiency and ensure high-quality results. One key feature is the integration of servo-driven systems, which provide greater control over the heating and forming process. This precision ensures that each thermoforming machine cycle produces uniform containers that meet the required specifications for heat resistance, strength, and durability.

Another important aspect of advanced thermoforming machines is their energy efficiency. With innovations in heating systems, these machines reduce energy consumption while maintaining high production speeds. The reduction in energy costs, combined with faster production cycles, enables businesses to improve their bottom line while meeting the increasing demand for heat-resistant food packaging solutions.

Moreover, the versatility of plastic packaging machines allows for the production of containers in various shapes, sizes, and material types. By accommodating different plastic materials, such as PET, PP, and PLA, thermoforming machines can cater to a wide range of food packaging needs. This adaptability is essential for companies looking to meet the diverse requirements of their customers and offer eco-friendly packaging options without compromising on quality or performance.

Material Innovations: Ensuring Durability and Heat Resistance

Innovations in materials play a crucial role in enhancing the durability and heat resistance of thermoformed food containers. Advances in plastic materials, such as high-performance resins, allow thermoforming machines to produce containers that can withstand higher temperatures without losing their shape or strength. This is particularly important for food containers that are exposed to heat during reheating or storage.

The choice of material is a key factor in ensuring that food packaging can safely handle hot food products. Many manufacturers are now turning to recycled plastics, which offer both environmental and performance benefits. Thermoforming machines are capable of working with these advanced materials, allowing businesses to produce sustainable, heat-resistant containers that meet both environmental and functional requirements.

In addition to heat resistance, material innovations also focus on improving the overall durability and longevity of food containers. Containers made from high-quality thermoformed plastics are less prone to cracking or warping under extreme conditions. This ensures that food products remain protected during transportation and storage, providing consumers with reliable packaging that keeps their meals safe and fresh.

Sustainable Manufacturing Practices for Food Packaging

Sustainability is becoming increasingly important in food packaging, with both consumers and regulatory bodies demanding more eco-friendly solutions. Thermoforming technology supports sustainability by allowing manufacturers to use recyclable and biodegradable materials in the production of food containers. The ability of thermoforming machines to work with a range of sustainable plastics ensures that food packaging can be both environmentally responsible and functional.

At Inpak, we prioritize sustainability in our thermoforming systems, offering solutions that minimize waste and maximize resource efficiency. By using advanced plastic packaging machines, companies can reduce their environmental impact while still meeting the growing demand for high-performance food containers. Sustainable practices not only contribute to environmental protection but also help businesses align with consumer preferences for greener packaging solutions.

In addition to using sustainable materials, thermoforming machines can also be optimized to reduce energy consumption and material waste. The precise nature of the thermoforming process ensures that plastic sheets are used efficiently, reducing excess material. Combined with the ability to work with recycled plastics, this results in more sustainable production practices that benefit both businesses and the planet.

Enhancing Efficiency and Quality with Inpak Thermoforming Solutions

Enhancing Efficiency and Quality with Inpak Thermoforming Solutions

At Inpak, we are committed to enhancing production efficiency and product quality through our innovative thermoforming solutions. Our machines are designed to maximize throughput while maintaining the highest standards of precision and durability. By integrating advanced control systems, servo drives, and energy-efficient technologies, Inpak thermoforming systems help businesses streamline their production processes and reduce operational costs.

The flexibility of Inpak thermoforming machines allows for the production of customized containers that meet the unique needs of the food packaging industry. Whether it’s heat-resistant containers for hot meals or environmentally friendly packaging solutions, our machines can accommodate a wide range of materials and designs. This ensures that businesses can offer tailored packaging options that meet consumer demand for convenience, sustainability, and quality.

In addition to improving efficiency, Inpak thermoforming solutions enhance product quality by ensuring precise molding and consistent results. Our machines are built to handle high-volume production while delivering high-quality, heated plastic food containers that meet industry standards. With Inpak, businesses can improve both their production efficiency and product quality, positioning themselves as leaders in the competitive food packaging market.