Durability and Performance in Vacuum Thermoforming Machines

Vacuum thermoforming machines rank among the industrial production equipment that require high durability and performance. These machines produce high-quality packaging by heating plastic sheets and vacuum-forming them over molds. Vacuum thermoforming machines are particularly known for their durability and long-lasting operation. The packaging produced is ideal for long-term use due to both its aesthetic and functional qualities. The machines’ performance increases production speed, enhancing efficiency while requiring minimal maintenance, which offers economic benefits to businesses.

Table of Contents

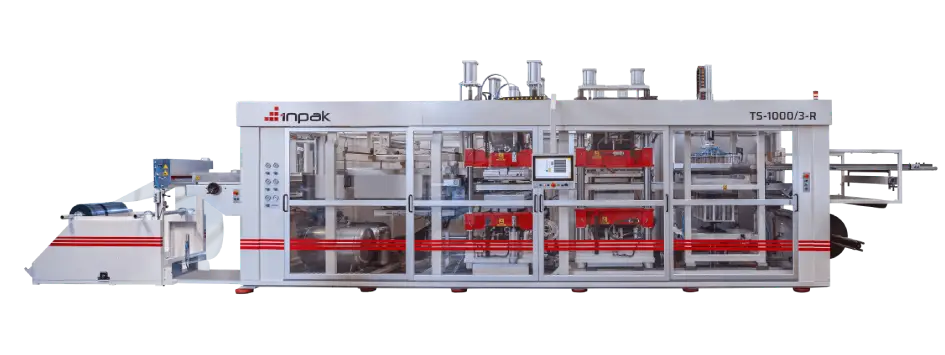

In terms of durability, vacuum thermoforming machines are built with strong materials and feature long-lasting designs. They can operate smoothly even under demanding production conditions. Manufactured using high-quality components and advanced technological systems, these machines deliver consistently high performance, especially in large-scale manufacturing. Producers can accelerate their production processes by using plastic packaging machines and gain a competitive edge by maintaining uninterrupted operation.

Regarding performance, thermoforming machines achieve high cycle speeds and enable large-scale production. These machines can reach production speeds of up to 75 cycles per minute. This capability provides an excellent advantage for companies with high-volume manufacturing needs. Additionally, vacuum thermoforming machines are equipped with optimized heating systems that ensure energy efficiency. Compared to traditional methods, they can reduce energy consumption by up to 30%, lowering costs and supporting environmentally friendly production processes.

Durability and Performance in Vacuum Thermoforming Machines

What Are Vacuum Thermoforming Machines?

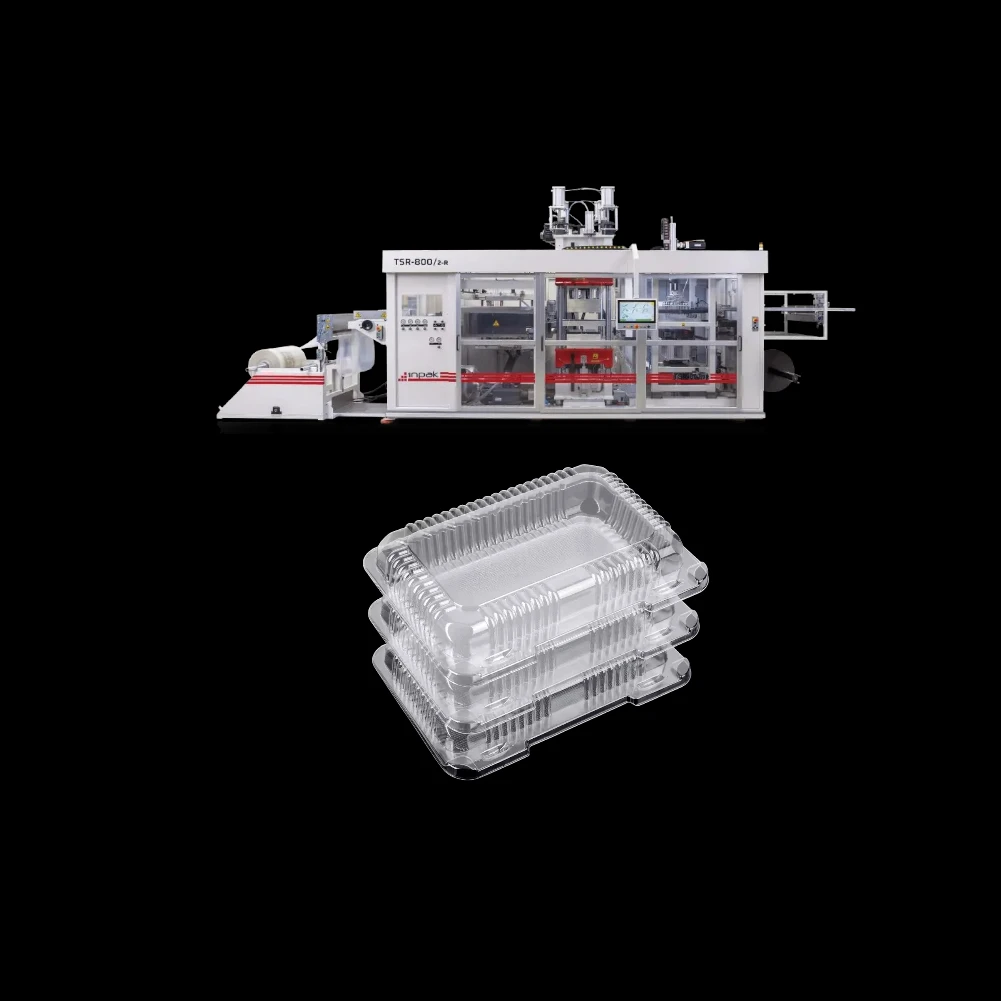

Vacuum thermoforming machines are high-tech devices that heat and soften plastic sheets, then use vacuum pressure to shape them into desired forms. Thermoform machines are commonly used for packaging in food, medical, and industrial sectors. After heating the plastic sheet, vacuum pressure is applied to the mold to form the shape—a process that requires both speed and high precision. The vacuum applied inside the plastic sheet accelerates shaping and ensures detailed, smooth results.

Thermoforming machines are among the most effective solutions in plastic packaging equipment. With these machines, specialized packaging solutions can be produced for different industries. In the food sector especially, vacuum thermoforming machines serve as food packaging machines that meet hygiene standards and ensure healthy product packaging. These machines enable the production of durable and attractive packaging, deliver rapid results during production, and offer innovative solutions to the industry.

The working principle of vacuum thermoforming machines is a simple yet effective method involving the shaping of heated plastic sheets under vacuum pressure. These machines operate with high efficiency to meet broad production demands. Using thermoforming machines, plastic sheets can be shaped rapidly and accurately according to specific designs. They hold significant importance not only in food packaging but also in medical and industrial fields. For plastic packaging machine manufacturers, vacuum thermoforming machines provide a great advantage.

What Can Be Done With a Vacuum Thermoforming Machine?

Thermoforming machines are highly efficient tools for shaping various plastic materials. Thanks to thermoforming machine manufacturing, products usable in many sectors—such as food packaging, medical products, and industrial packaging solutions—can be produced. These machines not only form shapes but can also perform additional processes like cutting and packaging of plastic sheets. This capability speeds up production processes, enabling more products to be produced in less time.

In the food industry, products like egg cartons, yogurt and ayran cups, and ready meal containers produced with plastic packaging machines enjoy high demand. Additionally, plastic packaging machines are widely used in industrial applications. In electronics and automotive sectors, protective packaging that enhances the safety of transported parts is a crucial element. Thermoforming machine manufacturers can provide customized solutions to meet special production needs through these machines.

Vacuum thermoforming machines also play an important role for medical packaging machine manufacturers. Packaging that complies with sterilization requirements—such as syringe packaging—frequently uses vacuum thermoforming machines. These machines are ideal for highly precise shaping and sterilization processes. They also ensure products are safely packaged, increasing customer satisfaction.

Durability in Vacuum Thermoforming Machines

These thermoforming machines are known for their durability and long-lasting construction. They maintain high efficiency without performance loss even under intense operating conditions. The vacuum pressure applied during the shaping of plastic sheets puts structural strain on the machine; however, thermoforming machine manufacturers maintain high-quality standards to ensure durability. These machines are designed to minimize maintenance needs and sustain continuous high-yield production.

Vacuum thermoforming machines can work compatibly with various types of plastic materials, which may affect their durability depending on the material. Machines that operate smoothly with plastics such as PET, PP, and PS are especially made from durable materials for use as food packaging machines. These machines are designed to withstand both high temperatures and harsh working conditions. Plastic packaging machine manufacturers use these machines to guarantee the durability and quality of their products.

The durability of the machines is also linked to energy efficiency. Since vacuum thermoforming machines are built from high-quality materials, they can produce more products with less energy. This feature reduces production costs and increases environmental sustainability. In summary, vacuum thermoforming machines provide not only durable but also energy-efficient solutions.

Durability and Performance in Vacuum Thermoforming Machines

Performance in Vacuum Thermoforming Machines

The performance of vacuum thermoforming machines delivers high efficiency by combining production speed with forming accuracy. These machines can achieve high cycles per minute to meet large-scale production demands. Production processes using thermoforming machines are carried out quickly and precisely. This advantage is particularly noticeable in sectors requiring high-volume plastic packaging production.

High performance relates not only to speed but also to precision. Products formed by vacuum thermoforming machines have perfectly defined edges and surfaces. This precision is critically important for food packaging machines to meet hygiene standards. Additionally, in industrial applications, these machines provide high performance for creating complex shapes and details.

A good thermoforming machine manufacturer offers features that enhance machine performance. With automated processes and industrial PC-based controls, production errors are minimized. Consequently, high-quality manufacturing is achieved with low error rates and optimized processes. This offers manufacturers cost savings and faster production times.

Durability and Performance in Vacuum Thermoforming Machines

What Should You Consider When Choosing a Thermoforming Machine?

Several important factors should be considered when selecting a thermoforming machine. First, machine capacity must be evaluated. Based on your production volume and demands, you should choose a machine capable of operating continuously at high speeds. Energy efficiency is also a crucial factor. Energy consumption significantly affects long-term production costs, so machines that provide energy savings should be preferred.

Maintenance requirements must also be taken into account during selection. Vacuum thermoforming machines should be designed with minimal maintenance needs to ensure continuous operation and prevent production interruptions. Additionally, after-sales support and training services are important. A reliable thermoforming machine manufacturer should assist customers not only during production but also throughout installation and training processes.

Finally, the durability and lifespan of the machine must be considered. Plastic packaging machine manufacturers should prioritize making machines that are durable and long-lasting. This accelerates the return on investment for businesses and ensures the machines continue adding value over the long term.

Durability and Performance in Vacuum Thermoforming Machines

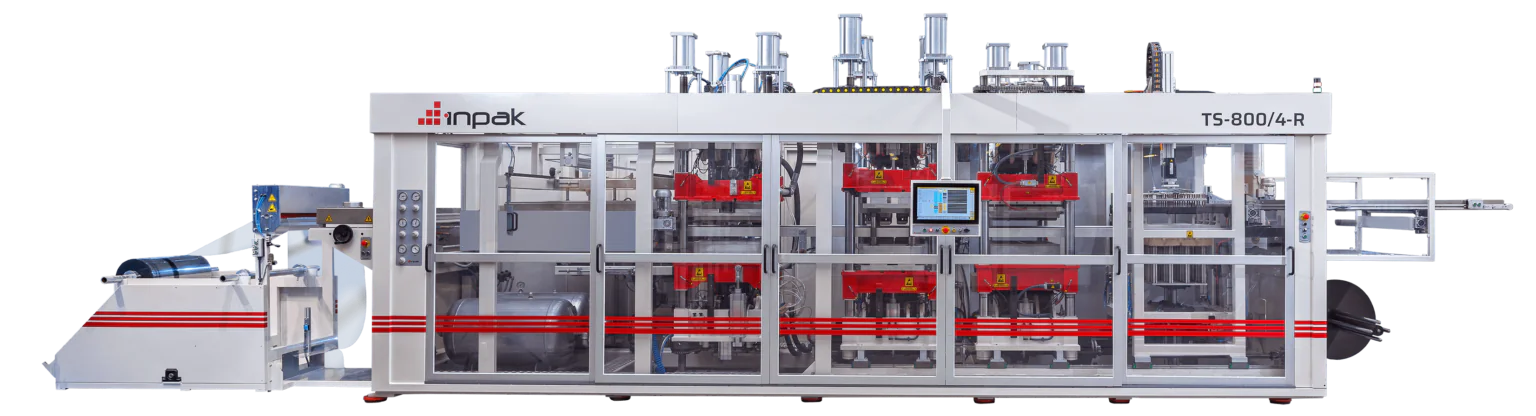

INPAK: Vacuum Thermoforming Machines Providing High Efficiency

INPAK is among the leading vacuum thermoforming machine manufacturers in the industry. We are known for machines that deliver high efficiency and stand out in plastic packaging machine production. Our vacuum thermoforming machines offer durable and high-performance solutions that speed up production processes and make them more efficient.

We prioritize energy efficiency in the design of our machines. Our vacuum thermoforming machines help businesses reduce costs by saving energy. The machines we provide guarantee not only efficiency but also high quality. INPAK is the ideal solution for plastic packaging machine manufacturers, focusing on increasing customer satisfaction.

In conclusion, as a thermoforming machine manufacturer and producer, we maintain our competitive advantage in the industry through our high-quality products and customer-focused approach. Vacuum thermoforming machines are a powerful solution capable of meeting every packaging need.