Factors Affecting Vacuum Forming Machine Price and Investment Value

Investing in a vacuum forming machine price requires careful consideration of multiple factors that can influence both upfront costs and long-term returns. Businesses in the plastic packaging and food packaging industries need to understand that thermoforming machines are not one-size-fits-all, and pricing can vary widely depending on production capabilities, material types, and the level of automation integrated into the machine. Companies looking to optimize their investment value must balance initial costs with operational efficiency and durability to ensure maximum return on investment.

Table of Contents

The size and complexity of a thermoforming machine significantly affect the vacuum forming machine price. Larger machines designed for high-volume thermoforming machine production naturally require more sophisticated engineering, higher-grade components, and additional automation features, all of which contribute to increased costs. At the same time, smaller machines may appear more affordable but can limit production capacity and flexibility, impacting a company’s ability to scale operations efficiently. Choosing the right machine involves a careful assessment of current and future production needs in line with business growth plans.

Investment value in plastic packaging machines goes beyond the initial purchase price. Operational costs, maintenance, energy consumption, and the machine’s ability to handle multiple material types play a critical role in determining overall profitability. A well-chosen Thermoforming machines can significantly reduce labor requirements, improve product quality, and streamline production processes, ensuring that the total cost of ownership aligns with business objectives. Companies that consider these factors can achieve long-term savings while maintaining high standards of efficiency and output.

Key Components Influencing Vacuum Forming Machine Cost

The vacuum forming machine price is heavily influenced by the quality of its key components. High-performance heaters, precision servo systems, durable transport chains, and advanced control software are essential elements that determine both production efficiency and machine longevity. For instance, machines equipped with advanced heating technology allow for better material distribution, consistent product quality, and reduced waste, all of which directly affect the overall investment value.

Another significant factor affecting thermoforming machine cost is the quality of vacuum and molding systems. Machines designed for heavy-duty industrial vacuum forming machine applications often include multiple vacuum zones, sensitive positioning mechanisms, and high-efficiency pumps. These components enhance precision and reliability, increasing the thermoforming machine cost but providing long-term benefits in production consistency and reduced downtime. For businesses operating in competitive sectors like food packaging, investing in robust equipment ensures a higher return through superior output.

Control systems and software integration also play a major role in shaping the vacuum forming machine price. Modern plastic thermoforming equipment often includes ergonomic interfaces, remote access, and customizable settings to optimize production parameters. These features improve efficiency and reduce operator error, which can save costs over time. Choosing machines with integrated automation can result in higher upfront costs but offers advantages in speed, precision, and adaptability, contributing to a more favorable total investment value.

How Machine Size and Production Capacity Impact Pricing

Machine size is one of the most direct determinants of vacuum forming machine price. Larger machines require more material, engineering complexity, and additional automation to handle the increased workload. This size increase not only affects the initial purchase cost but also impacts energy consumption, floor space requirements, and maintenance expenses. Businesses must evaluate their production needs carefully to avoid overspending on a machine whose capacity exceeds actual demand.

Production capacity is closely linked to thermoforming machine manufacturing efficiency. Machines with higher throughput can significantly reduce production cycles and labor requirements, making them more cost-effective in high-volume applications. However, these machines come with a higher thermoforming machine cost, particularly if they are designed for precise thermoforming machine production in sectors like food and medical packaging. Companies must weigh the benefits of increased capacity against the initial financial outlay to ensure sustainable investment.

The balance between machine size and production capacity also affects long-term operational costs. Larger, high-capacity plastic packaging machines may require more energy and more frequent maintenance, influencing the overall vacuum forming machine price from a total cost of ownership perspective. Businesses should consider both immediate needs and potential future growth when evaluating equipment, as investing in scalable machines can provide a competitive edge without excessive upfront expenditure.

Material Types and Their Effect on Thermoforming Machine Prices

The type of material a thermoforming machine can process is a significant determinant of vacuum forming machine price. Machines capable of handling high-temperature plastics like CPET or PLA require specialized heating systems, advanced stretch mechanisms, and robust construction to maintain consistent quality. These additional features increase both initial investment costs and maintenance requirements but are crucial for producing high-quality plastic thermoforming equipment suitable for food and medical applications.

Material versatility directly influences the overall value of thermoforming machines. Machines that can efficiently process multiple plastics, such as PET, PP, PVC, PS, OPS, and eco-friendly options like PLA, are priced higher due to the complexity of their engineering and flexibility in production. Choosing a machine capable of handling diverse materials allows manufacturers to adapt to market trends and customer demands without needing multiple machines, providing a cost-effective solution despite a higher vacuum forming machine price.

Specialized materials also impact energy consumption and production efficiency. For example, thicker or high-heat plastics require more precise temperature control and longer forming cycles, affecting operational costs. Thermoforming machine manufacturers account for these factors when designing equipment, ensuring that machines are not only compatible with various materials but also maintain efficiency, ultimately providing better ROI for businesses investing in high-quality plastic packaging machines.

Automation vs. Manual Operation: Cost and Efficiency Comparison

Automation significantly affects the vacuum forming machine price by adding advanced features such as servo-driven transport systems, automatic lubrication, remote access, and sensitive positioning. Automated thermoforming machines reduce the dependency on skilled labor, minimize production errors, and improve overall throughput. While the upfront cost may be higher, the long-term efficiency gains often justify the investment for companies seeking consistent, high-volume production in industries like food packaging.

Manual thermoforming machines are generally more affordable and may suffice for smaller production operations or businesses just entering the market. However, they lack the precision, speed, and consistency offered by automated machines, which can impact the quality of thermoforming machine production and limit scalability. Businesses must evaluate the trade-offs between initial cost savings and the potential for higher operational efficiency when deciding between manual and automated options.

Hybrid solutions are also becoming popular in industrial vacuum forming machine applications, offering selective automation features that reduce thermoforming machine cost without compromising key efficiencies. For example, machines with semi-automatic sheet handling and programmable forming cycles provide a middle ground for businesses aiming to improve production while managing budget constraints. These solutions allow for both flexibility and gradual integration of full automation over time.

Energy Consumption and Operational Costs in Vacuum Forming Machines

Energy consumption is a critical factor that directly impacts the vacuum forming machine price from a total cost of ownership perspective. Machines designed for high-efficiency heating, optimized vacuum systems, and precise control mechanisms consume less energy, reducing operational costs over time. For companies in the food packaging industry, minimizing energy consumption while maintaining production quality is essential for profitability and environmental sustainability.

Operational costs extend beyond energy, including maintenance, labor, and downtime expenses. High-quality thermoforming machines with advanced features like long-life systems, gapless joints, and sensitive positioning reduce wear and tear, leading to lower maintenance costs. Investing in efficient plastic packaging machines may increase initial thermoforming machine cost, but it ensures predictable and manageable operational expenses that positively affect overall ROI.

In addition, efficient machines often produce higher-quality output with fewer defects, further lowering the cost per unit. By minimizing waste and optimizing production cycles, companies investing in industrial vacuum forming machine solutions can achieve cost savings that exceed the additional upfront vacuum forming machine price, making high-quality equipment a smart long-term investment.

Market Demand and Regional Price Variations for Thermoforming Equipment

Market demand and regional factors significantly influence vacuum forming machine price. High-demand regions with advanced manufacturing infrastructure tend to have higher equipment costs due to increased competition, skilled labor, and regulatory requirements. Conversely, regions with lower demand may offer more affordable thermoforming machine cost, but buyers need to ensure that local support, spare parts availability, and technical service meet their requirements for efficient thermoforming machine production.

Regional variations in material costs and energy prices also affect thermoforming machine manufacturers and the final purchase price. Machines designed to handle locally available materials may be less expensive, while specialized machines for diverse plastics or environmentally friendly alternatives might be priced higher. Businesses need to consider these regional factors when evaluating the vacuum forming machine price to ensure they achieve both cost efficiency and operational capability.

Global market trends also impact pricing. As demand for sustainable packaging and high-quality plastic packaging machines increases, thermoforming machine suppliers may adjust pricing to reflect market conditions. Staying informed about industry trends and regional pricing helps businesses make strategic decisions when investing in industrial vacuum forming machine equipment, ensuring both competitive pricing and high-quality performance.

New vs. Used Vacuum Forming Machines: Which Offers Better ROI?

Choosing between new and used vacuum forming machines significantly affects investment value. New machines typically come with the latest technology, higher efficiency, and extended warranty coverage, but they also carry a higher thermoforming machine cost. These machines are ideal for businesses seeking reliable, high-quality production with minimal downtime and maximum flexibility in thermoforming machine manufacturing.

Used thermoforming machines can be more affordable and provide a lower initial vacuum forming machine price, making them suitable for startups or smaller operations. However, potential risks include increased maintenance needs, outdated technology, and limited lifespan. Buyers should carefully evaluate the condition of used equipment, availability of spare parts, and potential operational inefficiencies before making a decision.

For businesses focused on long-term investment, the ROI often favors new plastic thermoforming equipment due to energy efficiency, advanced automation, and higher production consistency. While the upfront cost may be higher, the reduced operational costs, improved product quality, and scalability ensure a better return compared to older, less reliable machines.

Customization and Additional Features: Are They Worth the Investment?

Customization plays a pivotal role in thermoforming machine cost and overall investment value. Machines tailored for specific production needs, such as specialized trays, containers, or food packaging formats, often include additional features like variable heating zones, servo-driven sheet stretching, and advanced stacking options. These enhancements increase the vacuum forming machine price but provide significant advantages in flexibility, quality, and production efficiency.

Additional features also improve operational efficiency and reduce labor requirements. Machines with remote access, automated lubrication systems, and sensitive positioning mechanisms allow operators to manage thermoforming machine production more effectively. The ability to integrate these custom solutions into existing workflows ensures that businesses can adapt to evolving market demands without investing in entirely new machines, adding value to the initial investment.

Ultimately, investing in customized thermoforming machines enables manufacturers to differentiate themselves in competitive sectors such as food packaging and medical equipment. While the initial vacuum forming machine price may be higher, the ability to produce high-quality, tailored products efficiently translates into stronger market positioning and higher ROI over time.

Maintenance and Long-Term Costs of Vacuum Forming Machines

Maintenance is a critical factor affecting the total vacuum forming machine price and investment value. Machines designed for durability, such as those with long-life systems, gapless joints, and high-quality bearings, require less frequent servicing and experience fewer breakdowns. For businesses relying on plastic packaging machines, minimizing maintenance ensures continuous production and reduces unplanned expenses, contributing to long-term profitability.

Operational reliability also depends on proper preventative maintenance. Regular servicing of heaters, vacuum pumps, transport chains, and servo systems extends the lifespan of thermoforming machines while maintaining consistent product quality. Companies investing in high-quality equipment benefit from lower cumulative maintenance costs, making a higher upfront thermoforming machine cost more financially viable over the machine’s lifecycle.

Long-term costs also include energy consumption, material waste, and labor efficiency. Machines with advanced features, energy-saving mechanisms, and optimized control systems reduce these recurring costs. By considering maintenance and operational factors alongside the vacuum forming machine price, businesses can ensure that their investment provides sustainable value and reliable performance for years.

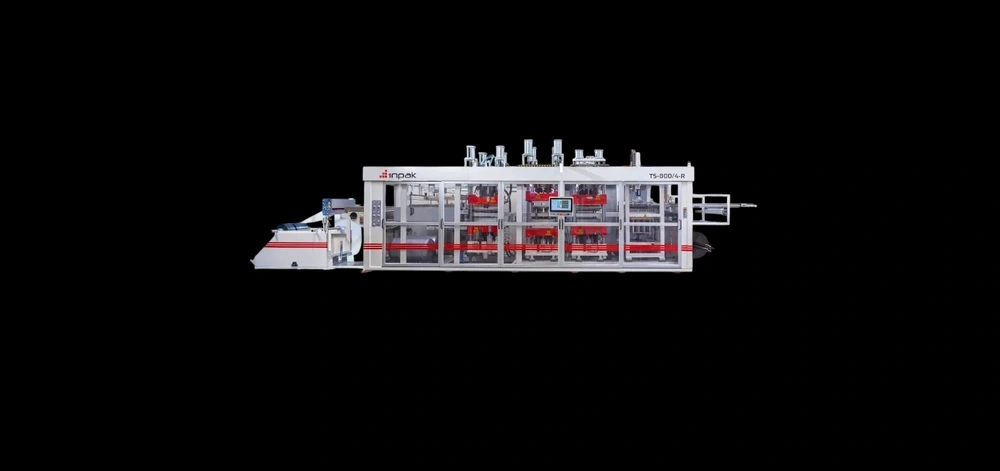

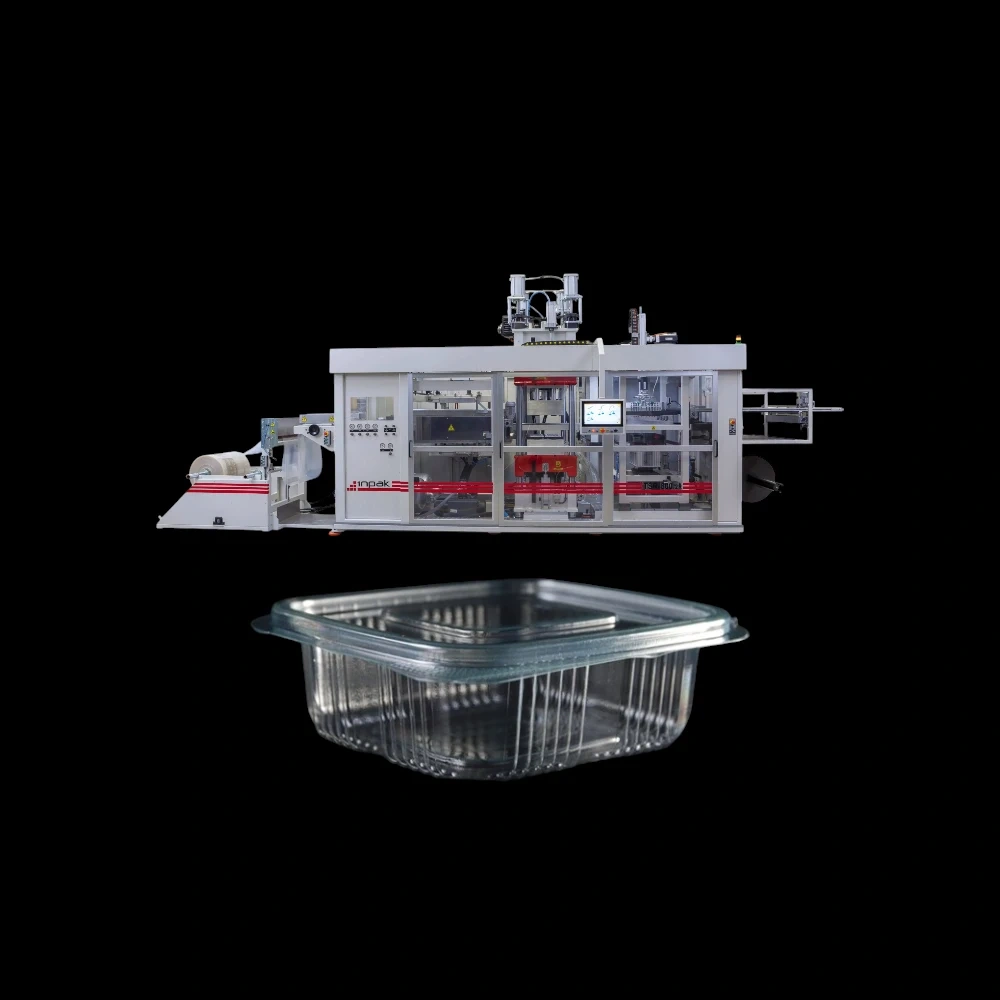

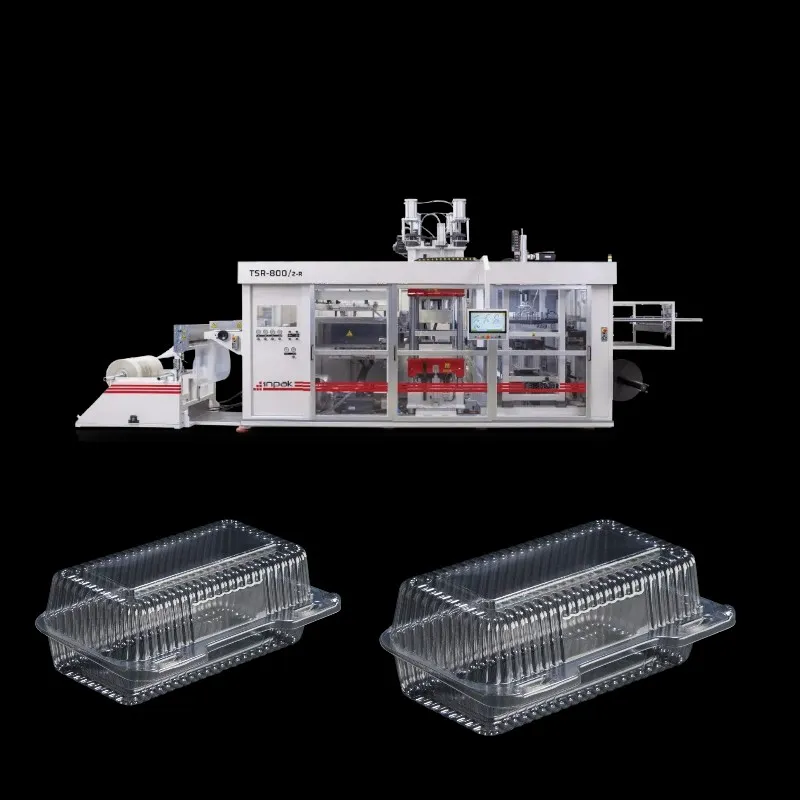

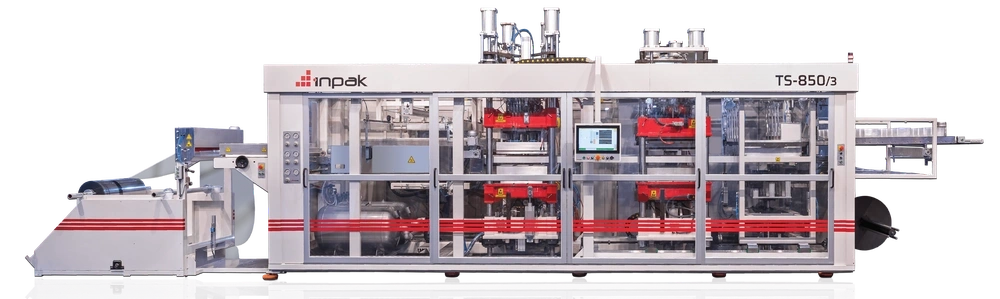

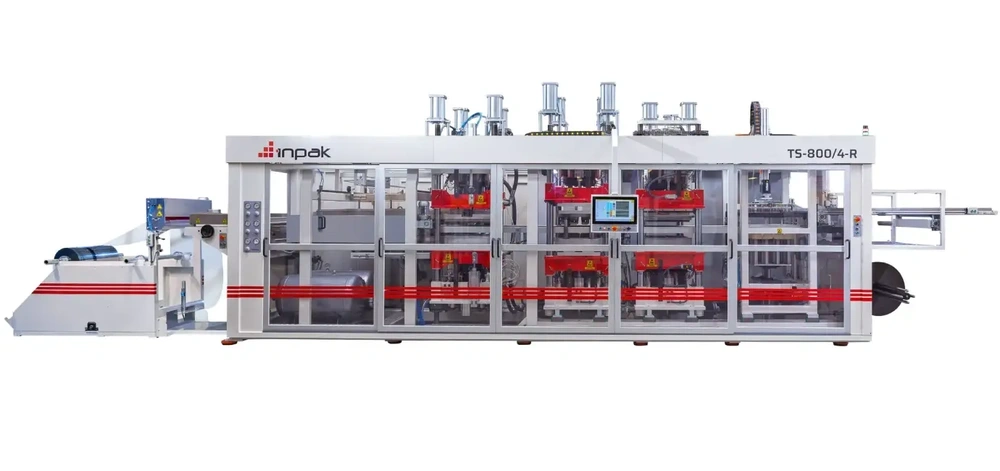

Why Choose INPAK for High-Quality and Cost-Effective Thermoforming Solutions?

INPAK offers industry-leading thermoforming machines designed for efficiency, durability, and high-quality output. Our machines support various materials, including PET, CPET, PP, PVC, PS, OPS, and PLA, allowing businesses to adapt to changing market demands. With advanced features such as servo-driven transport chains, sensitive positioning, remote access, and long-life systems, INPAK provides industrial vacuum forming machine solutions that deliver both operational efficiency and cost-effectiveness.

Our expertise in thermoforming machine manufacturing ensures that each machine meets rigorous quality standards, optimizing thermoforming machine production for food packaging, consumer goods, and industrial applications. We combine advanced automation, energy-efficient designs, and customizable options to create plastic packaging machines that maximize ROI while maintaining high-quality output. Our clients benefit from reduced operational costs, consistent performance, and flexible production capabilities.

Choosing INPAK means investing in trusted vacuum forming machine manufacturers with a proven track record. Our machines are engineered to provide excellent value, whether through affordable thermoforming machine cost, heavy-duty capabilities, or custom solutions for specialized applications. By prioritizing quality, efficiency, and adaptability, INPAK enables businesses to achieve long-term growth and success in competitive markets for plastic thermoforming equipment.