High-Performance Thermoforming Plastic Sheets for Global Markets

The demand for thermoforming plastic sheets continues to grow rapidly as industries worldwide seek versatile and durable materials for packaging and manufacturing. These sheets provide exceptional performance in various applications, from food packaging to industrial uses, owing to their ability to be precisely molded into complex shapes. Global markets favor thermoforming plastic sheets because they combine strength, flexibility, and aesthetic appeal, making them ideal for high-quality product presentation.

Table of Contents

Manufacturers producing thermoforming plastic sheets focus on delivering materials that meet stringent standards for safety, sustainability, and functionality. With advances in polymer technology, these sheets offer excellent clarity, barrier properties, and temperature resistance, essential for industries such as food and medical packaging. The continuous innovation in thermoforming plastic sheets also supports environmentally friendly initiatives through recyclable and biodegradable options.

Choosing the right supplier of thermoforming plastic sheets is crucial for businesses aiming to compete globally. Suppliers and manufacturers of thermoforming plastic sheets invest heavily in research and development to ensure their products meet diverse customer needs. From ultra-thin films to heavy-gauge sheets, the availability of various thicknesses enhances the versatility of thermoforming plastic sheets for different manufacturing processes and end-use applications.

What are Thermoforming Sheets?

Thermoforming sheets are specialized plastic sheets designed to be heated and shaped into custom forms using thermoforming machine. This manufacturing process involves heating the plastic to a pliable temperature and then molding it over a pattern or into a mold to create packaging, trays, containers, and more. The unique properties of thermoforming sheets make them indispensable in industries requiring both functionality and visual appeal.

The core advantage of thermoforming sheets lies in their ability to be formed quickly and efficiently while maintaining structural integrity. These sheets are compatible with various polymers, which allows manufacturers to tailor material properties such as rigidity, transparency, and barrier protection to specific applications. Using thermoforming plastic sheets ensures reliable production outcomes when paired with the right thermoforming machine and skilled operation.

With the rise of thermoforming machine manufacturers and suppliers specializing in thermoforming machine production, the use of thermoforming sheets has expanded into new markets. These sheets are now widely used in packaging, medical device housings, automotive parts, and more, highlighting their versatility. The integration of innovative thermoforming machines enhances sheet molding precision and productivity, making thermoforming sheets a preferred choice for manufacturers worldwide.

What Plastic Sheets are Best for Vacuum Forming?

When it comes to vacuum forming, selecting the appropriate thermoforming plastic sheet is vital to achieving optimal product quality. Common materials include PET, PP, PVC, PS, and PLA, all of which are widely used due to their excellent thermoformability and physical properties. These plastics offer varying degrees of rigidity, clarity, and barrier protection, making them suitable for different packaging and industrial needs.

PET and CPET sheets are particularly popular for food packaging due to their strength and heat resistance, ensuring food safety and extended shelf life. Meanwhile, biodegradable plastics like PLA are increasingly favored for eco-conscious applications, aligning with global sustainability goals. Manufacturers of thermoforming plastic sheets focus on optimizing these materials for vacuum forming processes to ensure smooth forming, minimal waste, and consistent results.

The choice of thermoforming sheets for vacuum forming also depends on thickness, transparency, and compatibility with thermoforming machines. Working with trusted thermoforming machine manufacturers and suppliers can help businesses select sheets that best fit their production requirements. High-quality thermoforming plastic sheets combined with state-of-the-art thermoforming machines ensure efficient vacuum forming processes that meet the high standards of today’s packaging and manufacturing sectors.

What Type of Plastic is Used for Thermoforming?

Various types of plastics are used in the production of thermoforming plastic sheets, each offering unique advantages for different applications. Common polymers include PET, PP, PVC, PS, OPS, CPET, and PLA, providing manufacturers a broad range of options depending on the desired product characteristics. These materials are formulated to be compatible with advanced thermoforming machines, enabling precision forming and consistent output.

PET is renowned for its clarity and barrier properties, making it ideal for food packaging, while PP offers flexibility and chemical resistance for industrial uses. PVC is often selected for its toughness and affordability, whereas PS and OPS are chosen for rigid packaging and display trays. The development of sustainable plastics like PLA is reshaping the industry by offering biodegradable options without compromising performance in thermoforming plastic sheet production.

Collaborating with experienced thermoforming machine suppliers and manufacturers ensures that the chosen plastics perform optimally in automated thermoforming machine lines. These partnerships guarantee that materials meet all regulatory and quality standards, enhancing production efficiency. Whether for food packaging machines or industrial thermoforming, the right plastic type combined with precision thermoforming machines defines product success.

Thermoforming Machines for Thermoformed Plastic Sheet Manufacturers

For thermoforming plastic sheet manufacturers, having access to advanced thermoforming machines is essential for maintaining competitive advantages. These machines provide the automation, precision, and flexibility required to shape sheets into complex designs for packaging and other applications. Investing in high-quality thermoforming machines ensures efficient production cycles and superior product quality.

Leading thermoforming machine manufacturers offer a variety of machines tailored to the needs of plastic sheet producers. From automatic thermoforming machine production systems to specialized industrial thermoforming machine production, these machines support a wide range of materials and thicknesses. Their integration improves production scalability and reduces material waste, key factors in the cost-effective manufacturing of thermoforming plastic sheets.

Furthermore, thermoforming machine suppliers provide ongoing support and customization to meet evolving market demands. By leveraging innovations in thermoforming machine manufacturing, manufacturers of thermoforming plastic sheets can respond to customer-specific packaging requirements and industry trends. The synergy between superior thermoforming machines and quality sheets defines success in plastic packaging machine industries.

Specialized Thermoforming Machine Production for Premium Plastic Sheets

Specialized thermoforming machine production caters to the sophisticated needs of premium thermoforming plastic sheets used in high-end packaging and medical applications. These machines are designed with features that ensure precise temperature control, material distribution, and forming accuracy, which are critical for premium sheet manufacturers aiming for flawless products.

Manufacturers seeking to produce premium thermoforming plastic sheets rely on thermoforming machine producers that prioritize quality and innovation. These producers incorporate servo-driven systems, adjustable heating configurations, and advanced lubrication to maximize machine performance and longevity. The specialized machinery also supports the production of ultra-thin and heavy-gauge sheets, ensuring versatility across product lines.

Choosing the right thermoforming machine supplier with expertise in premium sheet production enables manufacturers to optimize their processes and reduce downtime. These suppliers focus on thermoforming machine manufacturing companies with proven track records of delivering reliable, high-performance equipment. The result is a seamless integration of advanced machines with premium plastic sheet production, elevating product quality in competitive markets.

Optimized Extrusion and Thermoforming Manufacturing Processes

The manufacturing of thermoforming plastic sheets involves a precise combination of extrusion and thermoforming processes, both of which are optimized to ensure maximum quality and efficiency. Extrusion creates the base plastic sheet with uniform thickness and composition, while thermoforming shapes the sheet into the desired product using sophisticated thermoforming machines.

Optimization in extrusion and thermoforming requires close collaboration between sheet producers and thermoforming machine suppliers. This partnership focuses on reducing material waste, improving cycle times, and ensuring consistent product specifications. By employing automatic thermoforming machine production techniques, manufacturers can achieve high throughput and reproducible results critical to modern packaging demands.

Advancements in thermoforming machine manufacturing have enabled integration of pre-heating, vacuum forming, and servo controls into a single production line. This holistic approach to manufacturing thermoforming plastic sheets enhances energy efficiency and product precision. Companies investing in these optimized processes benefit from improved profitability and an enhanced ability to serve diverse market segments.

Ultra-Thin to Heavy-Gauge Thermoformable Plastic Sheets

Thermoforming plastic sheets come in a wide range of gauges, from ultra-thin films used in delicate packaging to heavy-gauge sheets for durable industrial components. This versatility allows manufacturers to tailor sheet thickness based on application requirements, balancing flexibility, strength, and cost. The ability to produce both extremes is supported by advanced thermoforming machines designed for precise control.

Ultra-thin thermoforming plastic sheets are often used for single-use food packaging, disposable trays, and lightweight containers, where material savings and clarity are essential. Conversely, heavy-gauge sheets find applications in automotive parts, medical device housings, and robust consumer goods packaging. Manufacturers rely on thermoforming machine manufacturers to supply machines capable of handling this diverse range of thicknesses efficiently.

This range in sheet thickness also influences material selection, as different plastics perform better at various gauges during thermoforming. Working with trusted thermoforming machine suppliers ensures that the machines can adjust to different sheet gauges without compromising quality. The result is a flexible manufacturing setup that can meet the demands of multiple industries using thermoforming plastic sheets.

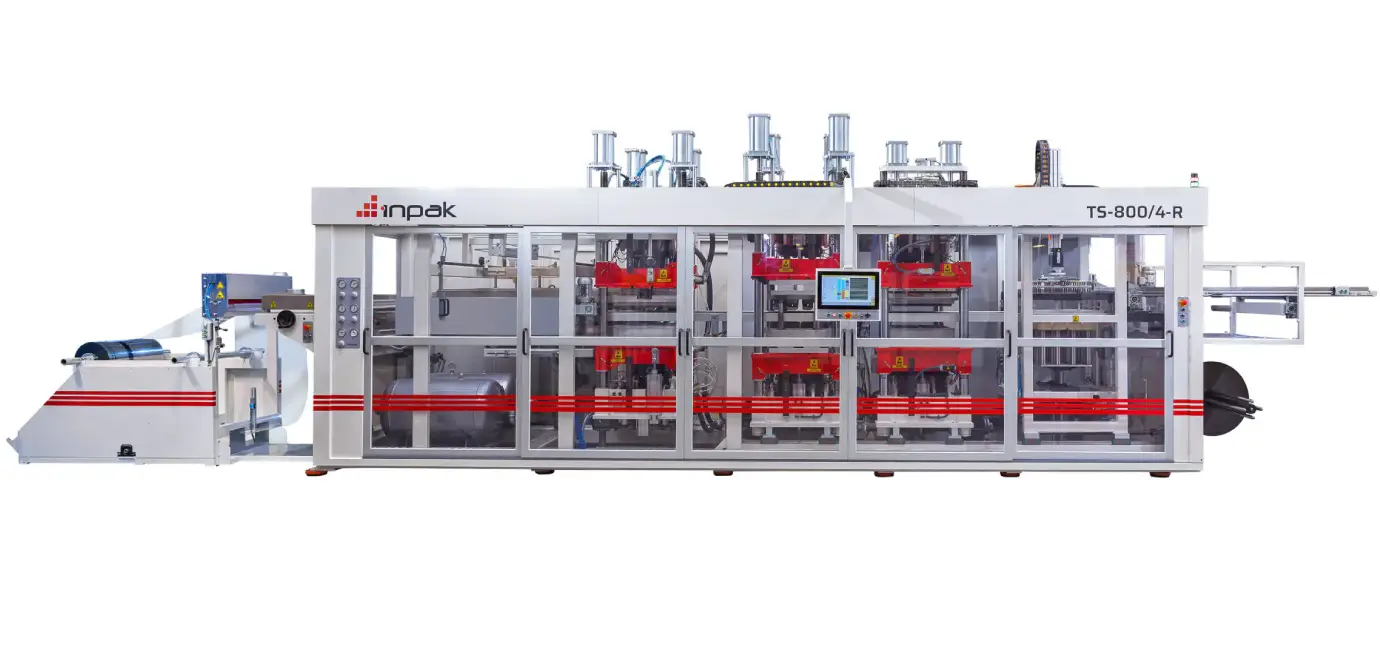

INPAK: Offering Excellence in Thermoforming Sheet Production Machines

INPAK stands out as a premier thermoforming machine manufacturer delivering cutting-edge solutions for thermoforming plastic sheet manufacturers globally. Their machines are engineered to combine precision, automation, and durability, supporting both plastic packaging machine and food packaging machine industries with consistent, high-quality output.

The company’s portfolio includes a wide array of thermoforming machines designed for diverse needs, from thermoforming packaging machine manufacturing to industrial thermoforming machine production. INPAK’s commitment to innovation is reflected in their integration of servo-driven transport systems, ceramic heaters, and remote monitoring, all of which optimize production efficiency and reduce downtime.

Partnering with INPAK means gaining access to comprehensive support from thermoforming machine suppliers who understand the complex requirements of modern plastic sheet production. Their expertise in thermoforming machine supply and manufacturing makes them an ideal choice for businesses seeking reliable and scalable thermoforming solutions. With INPAK, manufacturers elevate their capabilities in producing superior thermoforming plastic sheets for competitive global markets.