Thermoforming Packaging Machine Innovations by INPAK

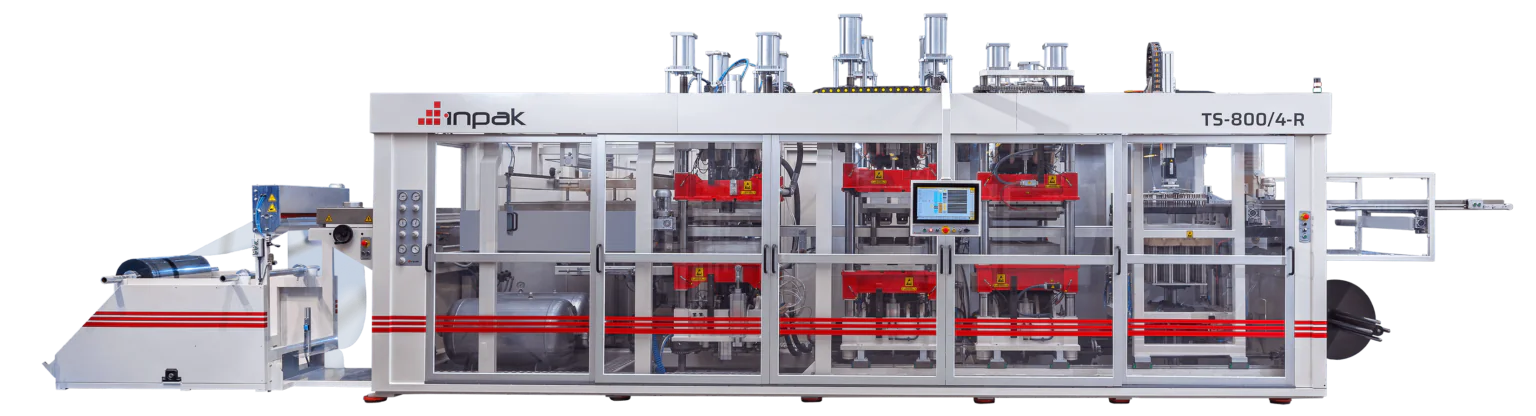

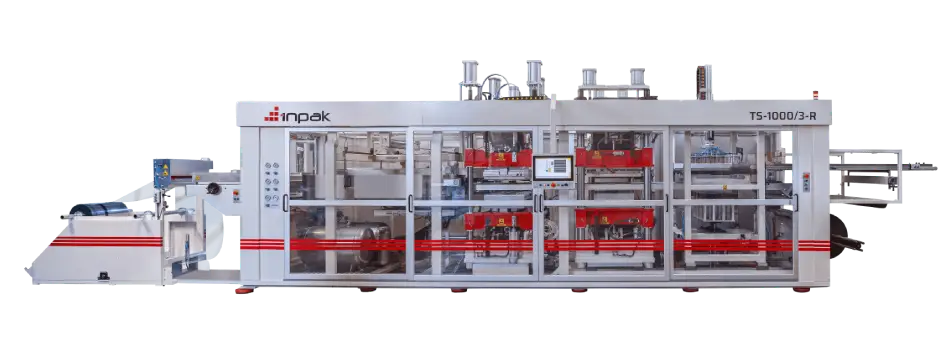

The packaging industry has evolved dramatically in recent years, especially with the increasing demand for efficient and sustainable solutions. One of the most significant innovations in this sector is the development of the thermoforming packaging machine. These machines are designed to create custom packaging solutions from plastic sheets by heating the material, forming it into specific shapes, and then trimming it to meet particular packaging needs. As an industry leader, INPAK continues to push the boundaries of thermoforming technology, offering state-of-the-art thermoforming packaging machinery that meets the diverse needs of businesses across the globe. With advanced automation features, INPAK ensures that businesses can achieve consistent and high-quality packaging with speed and precision.

Table of Contents

The technology behind thermoforming packaging machines has advanced significantly in recent years. The integration of robotic arms and automated systems has allowed for faster production cycles, reducing human error and enhancing the overall efficiency of the packaging process. By utilizing automated packaging machines, manufacturers can increase output while maintaining a high standard of quality. This is especially beneficial in industries like food packaging, where speed and hygiene are critical. INPAK’s thermoforming solutions also prioritize sustainability, utilizing eco-friendly materials like PET, CPET, and PLA, which are perfect for businesses looking to reduce their environmental footprint.

In addition to meeting the demand for speed and precision, INPAK’s plastic packaging machines are also customizable. Whether it’s food packaging, medical packaging, or consumer goods packaging, INPAK provides tailored solutions for every business. Their vacuum packaging machines are especially designed to offer enhanced molding precision and ensure that products are packaged in a way that maximizes shelf life and presentation. With an emphasis on durability and long-lasting performance, these machines provide significant value for companies that need consistent, reliable packaging solutions.

What is a Thermoforming Machine?

A thermoforming machine is a type of plastic packaging machine used to create packaging products by heating a plastic sheet and forming it into a mold. This process allows for the creation of a variety of packaging solutions, from simple trays to complex, custom designs. The process begins by heating the plastic sheet until it is soft enough to conform to the shape of the mold. Once the material has been molded, it is cooled and cut to the required dimensions. The result is a precise, durable packaging solution that is ideal for various applications, from food storage to medical packaging.

The thermoforming machine process can be used for a wide range of plastic materials, including PET, PP, PVC, and PLA. By utilizing different material types, businesses can choose the best option for their specific packaging needs. For example, food packaging machines often utilize PET for its durability and food-safe qualities, while other industries may prefer materials with higher heat resistance. The flexibility of the thermoforming packaging solutions provided by these machines makes them a versatile tool for manufacturers in various sectors. The ability to customize both the material and the shape of the packaging means that businesses can create packaging solutions that align with their unique needs.

One of the most important aspects of a thermoforming machine is its ability to offer scalability for different production volumes. From small-scale operations to large manufacturing plants, these machines can handle varying production capacities. INPAK’s range of thermoforming packaging machines can cater to businesses of all sizes, ensuring that whether you are a small startup or an established manufacturer, you can find a solution that fits your needs. This adaptability, combined with the precision and cost-efficiency of thermoforming machines, makes them a critical investment for any company involved in packaging.

Your Best Results with Customized Thermoforming Packaging Solutions

One of the most notable advantages of thermoforming packaging solutions is the ability to customize the packaging to suit the specific needs of the product. Whether it’s a delicate food item that needs airtight sealing or a medical device that requires protective packaging, a thermoforming machine can produce a tailored solution. This customization not only enhances the protection of the product but also improves its visual appeal. With the ability to incorporate features like custom shapes, textures, and printed designs, businesses can elevate their product presentation and branding through bespoke packaging solutions.

Moreover, companies that manufacture thermoforming machines like INPAK offer a wide range of customization options to ensure that the packaging meets the precise requirements of the product and the customer. INPAK’s expertise in designing plastic packaging machines means that they can offer tailored solutions for industries ranging from food packaging to consumer goods and medical devices. Businesses can benefit from packaging that not only meets functional requirements but also adheres to industry-specific standards. For instance, in the food industry, packaging solutions must be safe, hygienic, and capable of preserving freshness, all of which can be achieved with the right thermoforming packaging machine.

The ability to customize packaging through thermoforming also allows manufacturers to offer unique, value-added services to their customers. By providing specialized packaging that reflects the quality of the product inside, businesses can stand out in competitive markets. Custom thermoformed trays, clamshells, and containers are popular in many industries because they provide a high level of protection and a professional appearance. With automated packaging machines from INPAK, companies can achieve these customized results quickly and efficiently, making thermoforming an invaluable part of the modern packaging industry.

Thermoform Packaging Machine For Commercial Food Manufacturing

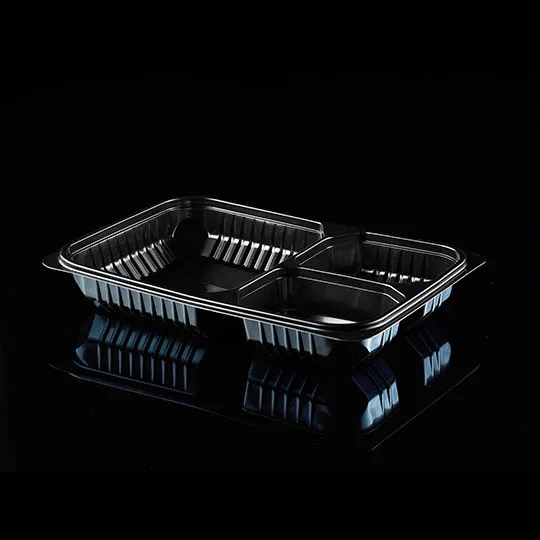

In the food manufacturing industry, packaging is a crucial element for preserving freshness, ensuring hygiene, and enhancing product presentation. Food packaging machines that utilize thermoforming technology are among the most effective solutions available today. These machines are designed to create airtight, leak-proof packaging that keeps food products safe during transport and storage. The ability to create custom-shaped containers, such as trays, clamshells, and blisters, is especially valuable in the food industry, where different products require different types of packaging.

INPAK’s thermoforming packaging solutions for food manufacturing are designed to meet the highest standards of quality and hygiene. These machines are capable of working with a variety of materials, including food-safe plastics that comply with industry regulations. By using thermoforming machines, food manufacturers can ensure that their products are packaged quickly, efficiently, and safely. Whether it’s fresh produce, processed foods, or ready-to-eat meals, thermoformed packaging ensures that the product remains fresh and appealing until it reaches the consumer.

The use of vacuum packaging machines in conjunction with thermoforming machines provides added benefits in food packaging. Vacuum packaging helps to extend the shelf life of products by removing air and sealing in freshness. This is particularly important for perishable food items that need to be kept fresh for as long as possible. Thermoforming packaging machines that integrate vacuum technology offer a streamlined solution for food manufacturers looking to improve their packaging processes and deliver products with the highest quality and freshness.

Benefits of Thermoform Packaging Machines for Manufacturers and Consumers

For manufacturers, investing in thermoforming packaging machines brings several key benefits. These machines offer high efficiency and reduced production costs by automating the packaging process. This leads to faster turnaround times, allowing manufacturers to meet high demand without sacrificing quality. The ability to run high-speed production cycles also helps businesses maintain a competitive edge in a fast-paced market. Additionally, thermoforming machines are known for their durability and longevity, making them a worthwhile investment for any manufacturer looking to streamline their packaging processes.

Consumers also benefit from thermoforming packaging solutions due to the improved protection, convenience, and sustainability they provide. Custom thermoformed packaging ensures that products remain intact during transit, reducing waste and improving the overall consumer experience. Furthermore, many plastic packaging machines used for thermoforming are designed to use eco-friendly materials, helping to reduce the environmental impact of packaging. As sustainability becomes an increasingly important factor for consumers, choosing thermoforming packaging machines that prioritize green practices can enhance a brand’s reputation.

In conclusion, both manufacturers and consumers stand to gain from the innovations brought by thermoforming packaging machines. By providing cost-effective, efficient, and customizable packaging solutions, these machines enable businesses to meet the growing demands of the modern marketplace while maintaining high standards of product quality and environmental responsibility. Partnering with a leading thermoforming machine manufacturer like INPAK ensures that companies have access to cutting-edge technology that can revolutionize their packaging processes.

The Advantages of Partnering with INPAK

Partnering with INPAK offers significant advantages for companies in need of thermoforming packaging solutions. With years of expertise and a reputation for excellence, INPAK provides access to top-of-the-line plastic packaging machines that can be customized to meet any need. Their range of automated packaging machines ensures that businesses can maintain high-speed production while minimizing operational costs. Furthermore, INPAK’s commitment to sustainability and innovation means that companies can rely on them for eco-friendly, cutting-edge packaging solutions that help meet both market demands and environmental regulations.

INPAK also offers excellent customer support, ensuring that businesses receive guidance throughout the process of selecting and implementing their thermoforming packaging machinery. Whether it’s for food packaging, consumer goods, or industrial applications, INPAK’s team of experts works closely with clients to provide tailored solutions that meet specific requirements. The ability to customize machines and integrate advanced features such as vacuum packaging machines and third motion servo plugs makes INPAK the ideal partner for businesses looking to elevate their packaging capabilities.

Finally, choosing INPAK as a partner ensures that businesses have access to the latest advancements in thermoforming technology. With INPAK, companies can remain at the forefront of the packaging industry, offering innovative, high-quality products that meet consumer expectations and enhance operational efficiency.