INPAK Thermoforming Machine Solutions for Efficient Production

Thermoforming machines are at the heart of modern plastic production, providing highly efficient solutions for creating durable and precise products. These plastic forming machines use heat to mold various materials into shapes, offering flexibility in production and cost-effectiveness. INPAK Thermoforming Machine Solutions for Efficient Production stand out in this field by delivering innovative systems that enhance both speed and accuracy.

Table of Contents

Thermoforming technology has evolved significantly in recent years, allowing for faster and more reliable production processes. As industries demand faster turnaround times and more customized packaging, the importance of thermoforming machines in meeting these needs has never been more significant. Companies that manufacture thermoforming machines, such as INPAK, offer advanced thermoforming solutions designed to increase productivity, improve quality, and reduce costs.

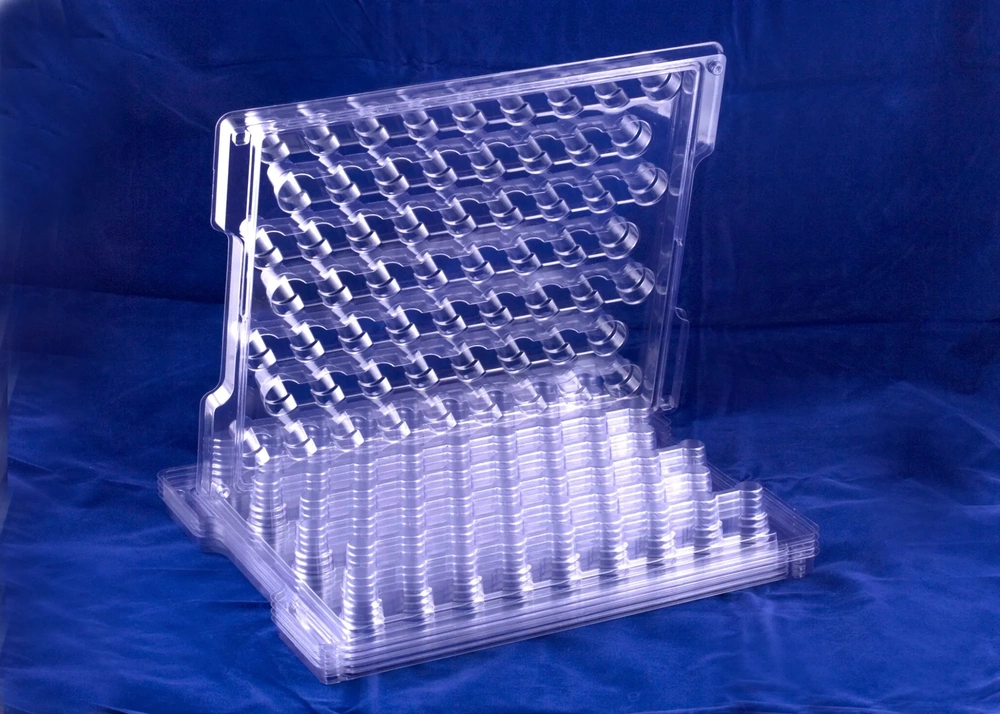

The thermoforming machine operates by heating a plastic sheet until it becomes pliable and then forcing it into a mold. This process allows for the creation of complex shapes with precision, and it is widely used across industries like food packaging, medical packaging, and consumer goods. Plastic processing machines are essential in the production of everyday items, from containers to custom packaging solutions. With vacuum thermoforming, the material is drawn into the mold using vacuum pressure, ensuring that even the most intricate shapes can be formed with minimal waste. The adaptability of thermoforming technology makes it an indispensable tool in manufacturing.

As a leading thermoforming machine manufacturer, INPAK has revolutionized the way companies approach plastic packaging and molding. By leveraging high-efficiency thermoforming machines, businesses can significantly improve their production output while reducing operational costs. The integration of automation in automatic thermoforming machines further enhances the consistency and repeatability of the process, making it easier for manufacturers to meet customer demands without compromising quality.

What is a Thermoforming Machine?

A thermoforming machine is a specialized piece of equipment used in the plastic processing industry to shape plastic sheets by heating them until soft and then forming them into specific molds. This method is highly versatile and cost-effective for producing a variety of plastic products. The heat forming process in these machines allows manufacturers to produce items with complex shapes that would otherwise be difficult to achieve using other manufacturing methods. Thermoforming is essential for creating products that need to be lightweight yet durable, such as packaging materials, trays, and medical products.

The versatility of plastic forming machines is one of the reasons why they are widely used in industries such as food packaging, medical, and industrial sectors. These machines allow for precise shaping of plastic materials like PVC, PET, and PP, which are commonly used for food containers and medical trays. Thermoforming machines are capable of working with various materials, enabling businesses to select the best material for their specific needs while ensuring that the final product is both functional and aesthetically pleasing. The process can be repeated with high accuracy, making it ideal for large-scale production runs.

Additionally, vacuum thermoforming is a popular variation of thermoforming, where a vacuum is applied to the heated plastic sheet to draw it into a mold. This results in tighter, more accurate fits for products like food packaging. The flexibility of thermoforming technology means that it can be adapted to a variety of industrial needs, making it a go-to solution for manufacturers looking for high-efficiency production methods. Whether you’re producing medical packaging or plastic packaging machines for food items, the thermoforming machine can help streamline production and lower costs.

What Are the Different Types of Thermoforming Machines?

There are several types of thermoforming machines designed to cater to various industrial applications. The most common types include the single-station thermoforming machine, multi-station thermoforming machine, and rotary thermoforming machine. Each type is tailored to a specific production need, with features that enhance the efficiency and scalability of the thermoforming process. Industrial thermoforming machines can handle high-volume production, making them ideal for large manufacturers. They are designed to produce products quickly while maintaining consistent quality throughout the production run.

The single-station thermoforming machine is typically used for smaller production runs and is ideal for creating custom packaging solutions. Rotary thermoforming machines, on the other hand, are perfect for high-volume applications as they are capable of producing products at a faster rate by moving the molds in a circular motion. These machines are particularly useful for industries where rapid production is essential, such as the food packaging industry. Furthermore, multi-station thermoforming machines allow manufacturers to form multiple molds simultaneously, increasing productivity and reducing labor costs.

One of the key benefits of high-efficiency thermoforming machines is their ability to work with a wide range of materials, including PET, PVC, and PLA, giving manufacturers the flexibility to choose the right material for their needs. Thermoforming with various materials enables companies to produce eco-friendly products that align with sustainability goals. Whether you’re producing plastic packaging machines or creating custom trays, choosing the right type of machine ensures that the process is optimized for your specific production needs.

INPAK Thermoforming Machines: Advanced Technology for High-Efficiency Production

INPAK’s high-efficiency thermoforming machines are at the forefront of plastic forming machines in the industry. These machines integrate the latest technology to enhance production capabilities and deliver superior results. Designed for a wide range of applications, INPAK’s advanced thermoforming solutions are equipped with features that enable quick setup, precise control, and reduced waste. The automation features in these machines ensure consistency in every cycle, making them a valuable asset for businesses looking to improve efficiency and reduce costs.

One of the standout features of INPAK’s machines is their compatibility with various materials, including eco-friendly options like PLA and PET. This allows businesses to create products that are not only high quality but also sustainable. With vacuum thermoforming, INPAK’s machines achieve precision molding by applying vacuum pressure to ensure a perfect fit for each product. This technology is essential for industries that require high levels of detail, such as food packaging and medical supplies. The ability to produce consistent, repeatable results with minimal waste is a key advantage of INPAK’s plastic processing machines.

Moreover, INPAK’s machines offer a variety of configurations to meet specific production needs. From automatic thermoforming machines that increase production speeds to customizable options for specialized molds, INPAK’s thermoforming technology provides a solution for every manufacturing requirement. With their focus on low-cost manufacturing solutions, INPAK ensures that businesses can improve profitability while delivering top-tier products that meet industry standards.

Sustainable Production: Recycling and Energy Efficiency

Sustainability is a growing concern in the manufacturing world, and INPAK’s thermoforming machines are designed with this in mind. The company’s focus on energy-efficient technology helps reduce energy consumption during the production process. By using advanced thermoforming technology, INPAK machines minimize energy waste and ensure that production runs as efficiently as possible. Additionally, many of INPAK’s machines are capable of working with recycled materials, further contributing to a more sustainable production process. The ability to integrate recycled plastics into the production line helps companies meet their environmental goals while maintaining high standards of quality and durability.

Vacuum thermoforming is an excellent example of how thermoforming can be optimized for sustainability. The process reduces material waste by ensuring that the plastic is molded into precise shapes, leaving less scrap material behind. This, combined with the ability to use eco-friendly materials like PLA, makes thermoforming an excellent choice for companies looking to reduce their environmental impact. INPAK’s machines are designed to support these sustainable practices, providing businesses with the tools they need to stay ahead in an increasingly eco-conscious market.

Moreover, INPAK’s commitment to flexible plastic production enables manufacturers to adapt their operations to meet shifting consumer demands for more sustainable packaging solutions. Whether it’s using biodegradable plastics or optimizing production processes to reduce energy consumption, INPAK’s high-efficiency thermoforming machines are helping businesses reduce their carbon footprint while maintaining productivity.

Industrial Applications of INPAK Thermoforming Machines

INPAK industrial thermoforming machines are used across various sectors, including food packaging, medical packaging, and consumer goods. In the food packaging industry, these machines are essential for creating durable, safe, and aesthetically pleasing packaging solutions. Whether it’s creating trays, containers, or vacuum-formed packaging, INPAK’s machines ensure that every product is made with precision and efficiency. These machines also help companies meet strict hygiene standards, ensuring that food products are packaged in a safe and sanitary manner.

The plastic packaging machines offered by INPAK also cater to the medical industry, where packaging needs to be sterile and reliable. Thermoforming in packaging industry is a critical process, and INPAK’s machines ensure that packaging for medical supplies maintains the highest standards. From vacuum thermoforming to mold production, INPAK’s machines deliver excellent results for industries requiring high-quality packaging solutions.

In addition to food and medical packaging, thermoforming is widely used in creating packaging for consumer goods, such as electronics, household products, and toys. INPAK’s plastic processing machines ensure that the packaging is not only functional but also appealing to consumers. With repeatable thermoforming processes, manufacturers can produce consistent results every time, helping to build brand trust and consumer satisfaction.

INPAK Thermoforming Machine Solutions for Efficient Production

Boost Your Production with INPAK’s High-Efficiency Thermoforming Machines

When it comes to boosting production efficiency, INPAK’s thermoforming machines are an invaluable asset to manufacturers. By investing in advanced thermoforming solutions, businesses can streamline their operations and reduce production costs while maintaining high-quality standards. INPAK’s automatic thermoforming machines offer automation capabilities that further increase throughput, reduce labor costs, and improve consistency.

The ability to produce large quantities of plastic packaging machines without sacrificing quality is a significant advantage for companies seeking to meet growing demand. Whether you’re in the food, medical, or consumer goods sector, thermoforming machines provide the flexibility and efficiency needed to stay competitive. With their focus on sustainability and low-cost manufacturing solutions, INPAK’s machines are the ideal choice for businesses looking to maximize their production capabilities while contributing to a greener, more sustainable future.