INPAK Thermoforming Machine Manufacturers Leading the Industry

In the evolving landscape of plastic packaging machines, INPAK stands out as a pioneering thermoforming machine manufacturer, delivering state-of-the-art solutions tailored for diverse industries. With decades of experience and innovative engineering, INPAK has secured its position as a trusted name among thermoforming machine manufacturers worldwide. Their commitment to quality, precision, and sustainability reflects in every machine they produce, catering to businesses looking to enhance efficiency and product appeal.

Table of Contents

The role of a thermoforming machine manufacturer has expanded beyond mere production to include customization, after-sales support, and technological integration. INPAK’s extensive portfolio includes machines that address the needs of the food industry, medical sector, and general packaging applications, making them versatile and adaptive to the changing demands of global markets. Their ability to combine advanced manufacturing with user-friendly interfaces ensures customers benefit from seamless operations and superior product outcomes.

Choosing the right thermoforming machine supplier is crucial for businesses aiming to maintain competitive advantage in packaging production. INPAK’s dedication to research and development, combined with a robust support network, positions them uniquely among thermoforming machine manufacturers. Their focus on delivering durable, energy-efficient, and innovative machines guarantees clients can rely on consistent performance and rapid return on investment.

INPAK Thermoforming Machine Manufacturers Leading the Industry

What is a Thermoforming Machine and How Does It Work?

A thermoforming machine is an essential piece of equipment in the plastic packaging industry, designed to mold plastic sheets into specific shapes and sizes for packaging applications. The process begins with heating a plastic sheet until it becomes pliable, after which it is shaped using a mold by applying vacuum or pressure. Once cooled, the formed plastic retains its shape, ready to be trimmed and used as packaging or trays.

The working principle of a thermoforming machine involves several coordinated steps including heating, forming, cooling, and trimming. Modern machines integrate sophisticated features like servo-driven chains, automatic sheet stretching, and vacuum technology to ensure precision and consistency. These capabilities allow manufacturers to produce high-quality thermoformed trays for food packaging and other applications with minimal waste and high speed.

INPAK’s machines incorporate ergonomic designs and advanced software interfaces to facilitate ease of use and remote monitoring. This integration enhances productivity while reducing downtime caused by errors or machine faults. The synergy of mechanical innovation and digital control makes the thermoforming machine production process both efficient and adaptable to different production scales and material types.

Key Applications of Thermoforming Machines in Various Industries

Thermoforming machines have found extensive use across multiple sectors due to their versatility and ability to produce customized packaging solutions. In the food industry, these machines manufacture hygienic, durable thermoformed trays for food packaging that ensure safety and prolong shelf life. Products like ready-meal containers, clamshell packaging, and bakery trays are typical outputs of these advanced machines.

Beyond food packaging, thermoforming machines serve critical roles in the medical industry by producing sterile packaging for surgical instruments, pharmaceuticals, and diagnostic kits. The precision and reliability of these machines make them suitable for stringent regulatory requirements, where product protection and contamination prevention are paramount. Additionally, the machines cater to industrial packaging needs by producing trays and containers for electronics, automotive parts, and consumer goods.

Environmental concerns have further expanded the scope of thermoforming machine manufacturers to support eco-friendly materials such as PLA and recyclable plastics. This evolution enables companies to meet sustainability goals without compromising packaging performance. The adaptability to different materials and stacking options allows manufacturers to serve diverse markets while maintaining operational efficiency.

INPAK Thermoforming Machine Manufacturers Leading the Industry

Benefits of Using Thermoforming Technology in Packaging

One of the primary advantages of thermoforming machines is their ability to deliver high-speed production without sacrificing quality. This results in cost-effective packaging solutions that help companies meet growing consumer demand. The energy-efficient designs of modern machines also contribute to lower operational costs, reducing the environmental footprint of packaging production.

Customizability is another significant benefit, as thermoforming machine manufacturers like INPAK provide tailored options to suit unique packaging requirements. From material selection to stacking configurations and mold design, businesses can create packaging that aligns perfectly with brand identity and product protection needs. This flexibility is vital in competitive markets where differentiation is key.

Durability and precision are inherent in the thermoforming process, ensuring that thermoformed trays for packaging withstand handling and transportation stresses. Furthermore, the hygienic nature of thermoformed food packaging promotes consumer safety and complies with strict industry regulations. The combination of these benefits makes thermoforming technology a preferred choice among packaging professionals worldwide.

What Sets INPAK Apart as a Leading Thermoforming Machine Manufacturers

INPAK distinguishes itself through a comprehensive approach to machine design and customer service. Their thermoforming machines are equipped with advanced features like remote access control, servo-driven transport chains, and automatic lubrication systems, ensuring longevity and ease of maintenance. These technical innovations underscore their commitment to delivering reliable and efficient plastic packaging machines.

The company’s investment in research and development allows INPAK to continuously improve its products, incorporating the latest technologies such as variable ceramic heater configurations and vacuum integration. This dedication ensures that customers receive machines that are not only high-performing but also adaptable to evolving industry standards and environmental considerations.

Beyond the machines themselves, INPAK provides unparalleled support and training, facilitating seamless integration of their equipment into production lines. Their expertise as a thermoforming machine manufacturer extends to consultation on optimizing packaging designs and materials, thereby maximizing the benefits clients derive from their investment. This holistic service model sets INPAK apart from many other thermoforming machine manufacturers.

INPAK Thermoforming Machine Manufacturers Leading the Industry

Why Partner with a Reliable Thermoforming Machine Manufacturer?

Selecting a trustworthy thermoforming machine manufacturer is essential for long-term success in packaging production. Reliability impacts everything from machine uptime to product quality and overall production costs. Partnering with established suppliers like INPAK assures businesses access to machines engineered for durability and backed by professional service.

A dependable manufacturer offers comprehensive warranties, timely spare parts availability, and responsive technical support, minimizing disruptions in production cycles. Additionally, such partnerships often include training and consultation services that empower staff to operate and maintain machines efficiently, reducing operational errors and maintenance expenses.

Furthermore, collaborating with an experienced thermoforming machine supplier ensures access to the latest technological advancements, keeping businesses competitive. Manufacturers committed to sustainability and innovation help clients meet environmental regulations while benefiting from energy-saving technologies. These factors highlight the importance of choosing the right partner in the thermoforming machine manufacturing sector.

INPAK Thermoforming Machine Manufacturers Leading the Industry

INPAK: Professional Thermoforming Machine Solutions

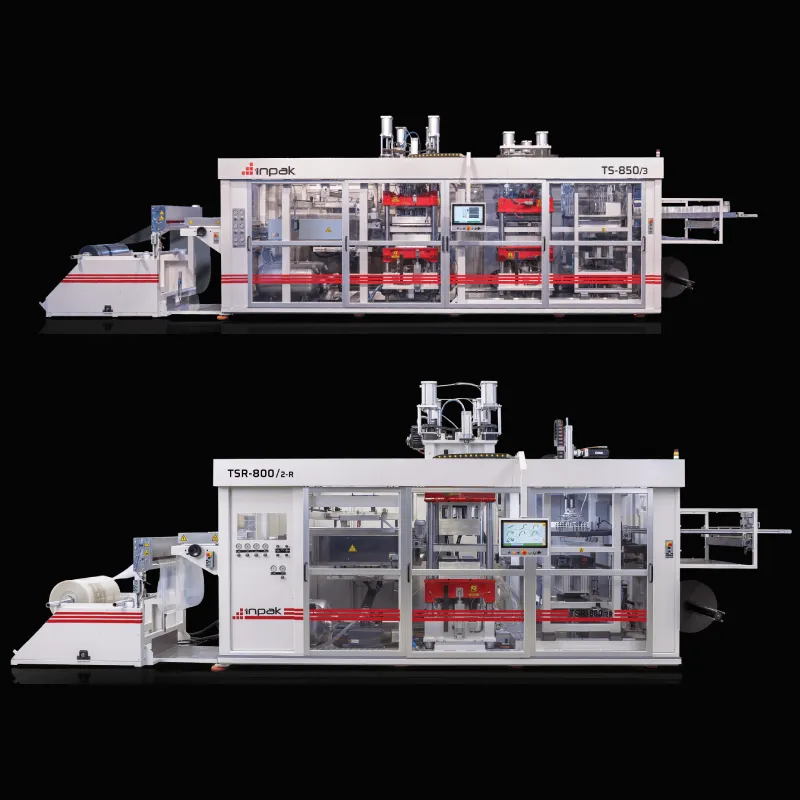

INPAK has solidified its reputation as a professional thermoforming machine manufacturer by offering a diverse range of machines designed to meet the specific demands of modern packaging industries. Their product line includes high-speed thermoforming packaging machines, vacuum forming units, and auxiliary systems like pre-heaters and elevator conveyors, providing comprehensive solutions.

Each INPAK machine is built with an emphasis on precision, reliability, and ease of use. The integration of user-friendly interfaces and remote access capabilities allows operators to monitor and control production remotely, enhancing flexibility and reducing downtime. These features make INPAK machines ideal for businesses focused on scaling production and improving quality control.

Moreover, INPAK’s commitment to supporting eco-friendly materials and energy-efficient processes positions them as leaders in sustainable packaging technology. Their customized solutions and responsive customer service ensure that clients receive tailored machines and ongoing support to optimize their packaging operations. This customer-centric approach defines INPAK’s success in the competitive world of thermoforming machine manufacturing.