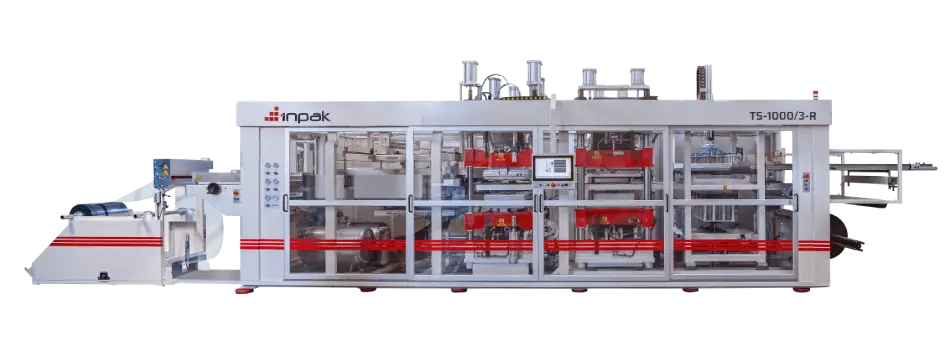

INPAK Thermoforming Machine for Food Packaging

Food packaging is a crucial component of the food industry, ensuring the safety, longevity, and convenience of food products. As consumer demand grows for both convenience and sustainability, food packaging must meet ever-evolving standards for freshness, hygiene, and environmental impact. In this dynamic market, the use of advanced thermoforming machine for food packaging has become a game-changer. These machines enable the production of high-quality, durable packaging that not only meets the needs of manufacturers but also enhances consumer experience. Thermoforming machine for food packaging allows manufacturers to create customized, precision-made containers that protect food and make transportation easier, ensuring it arrives at the consumer in optimal condition.

Table of Contents

With the rise of eco-conscious consumers, packaging manufacturers are increasingly turning to vacuum Thermoforming machines for food packaging. This process reduces material usage and enhances the efficiency of the packaging process, making it a key tool for sustainable food packaging. These food packaging machines also provide superior protection against contamination, a critical aspect in the food industry. The capability to produce flexible food packaging machines makes thermoforming equipment highly versatile, as it can be used for a variety of products, including fresh produce, meat, dairy, and convenience foods. INPAK’s thermoforming machines for food packaging are designed with these needs in mind, delivering the perfect balance of efficiency, customization, and environmental responsibility.

In addition to meeting these practical needs, the technological advancements in thermoforming machine technology enable manufacturers to adopt automated systems, reducing the need for manual labor and decreasing production time. The latest food packaging machinery allows for high-speed production, which is crucial in meeting the increasing demand for packaged food. Thermoforming machine manufacturers like INPAK focus on developing equipment that can handle high-volume production without sacrificing quality or precision. The result is packaging that is not only functional but also cost-effective and environmentally friendly, a vital factor for companies in the competitive food packaging industry.

What is Food Packaging?

Food packaging refers to the materials used to wrap or contain food products for storage, transportation, and sale. The packaging serves as a protective barrier against contaminants, moisture, and air, which can spoil food. In addition to preservation, food packaging plays a significant role in ensuring food safety, providing consumers with vital information such as expiration dates, nutritional content, and ingredient lists. With the increasing demand for convenience and ready-to-eat meals, the packaging must also be user-friendly and capable of preserving the food’s quality over extended periods. As packaging materials evolve, so too does the technology used to produce them, with companies turning to innovative plastic packaging machines to meet these needs.

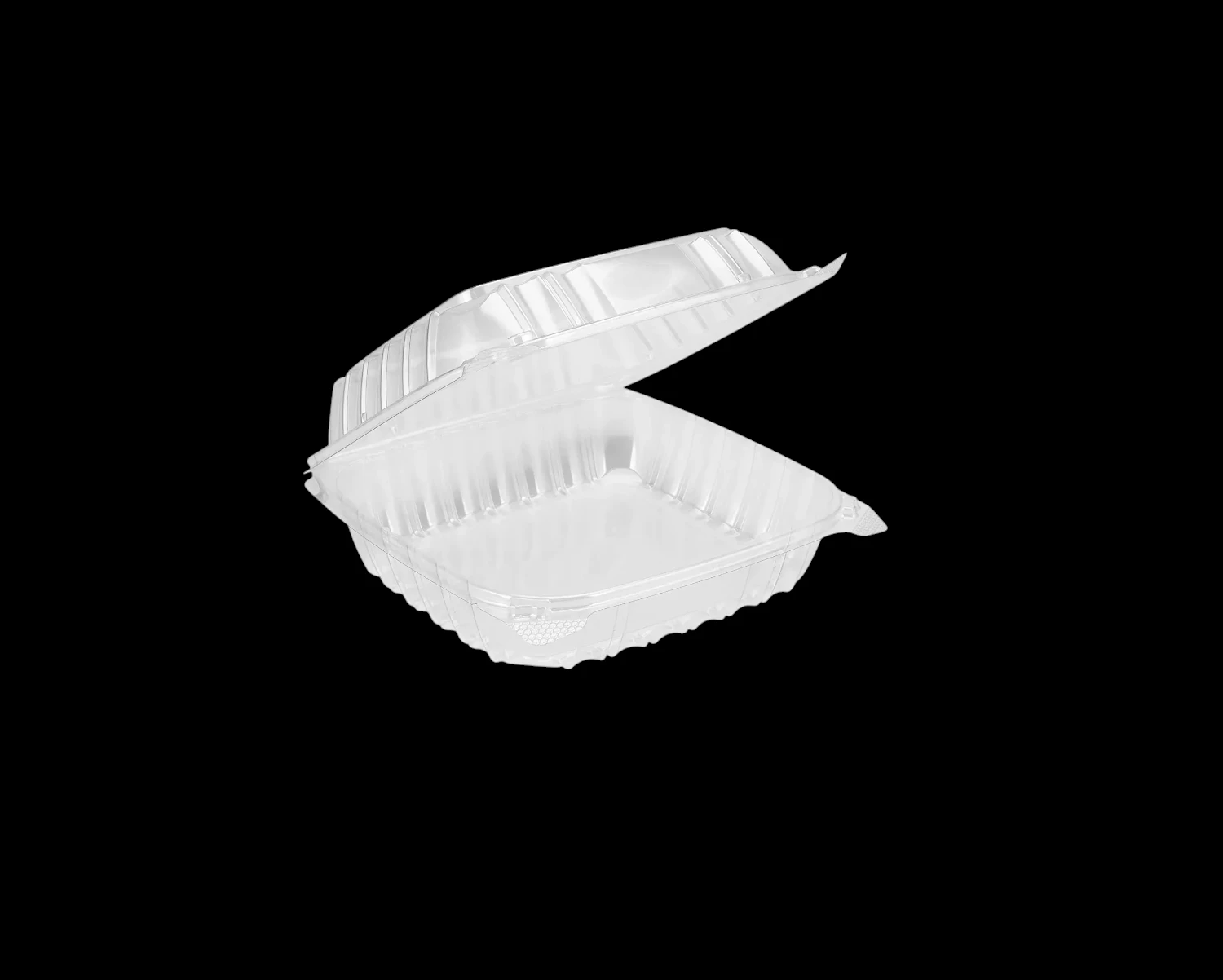

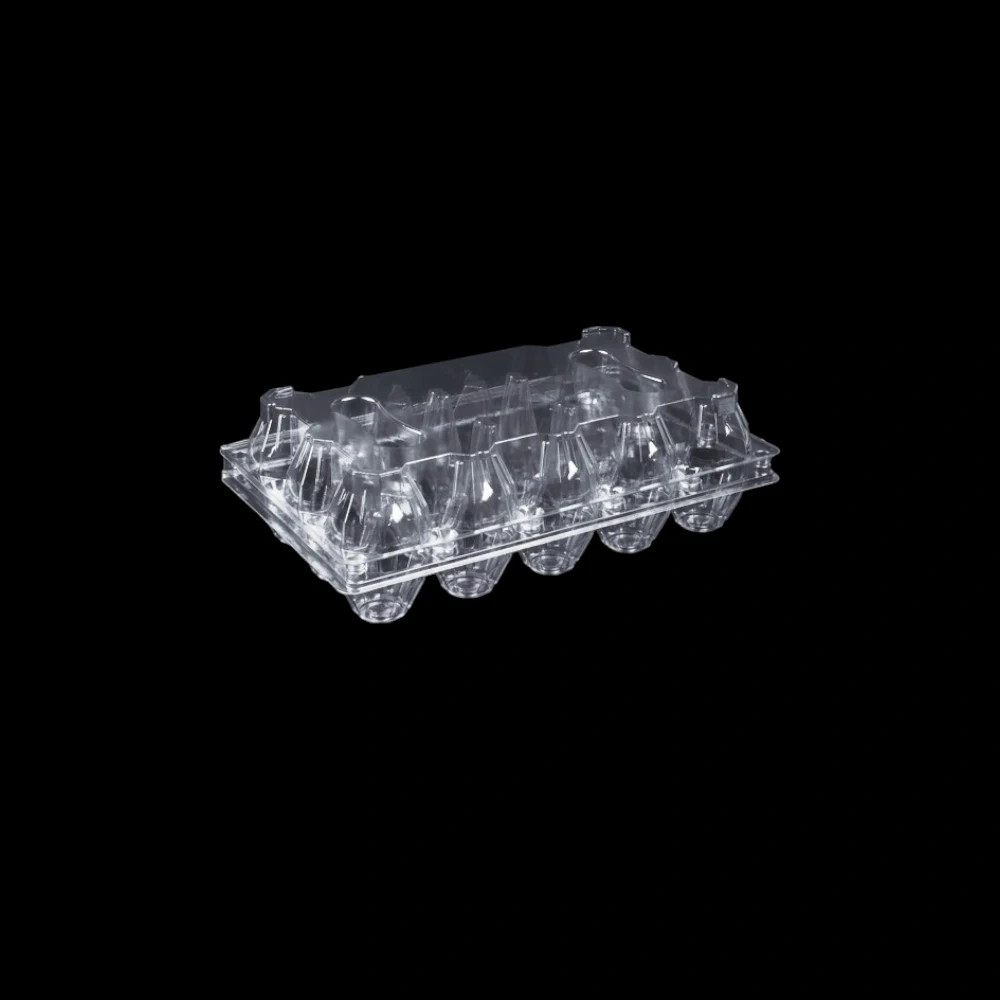

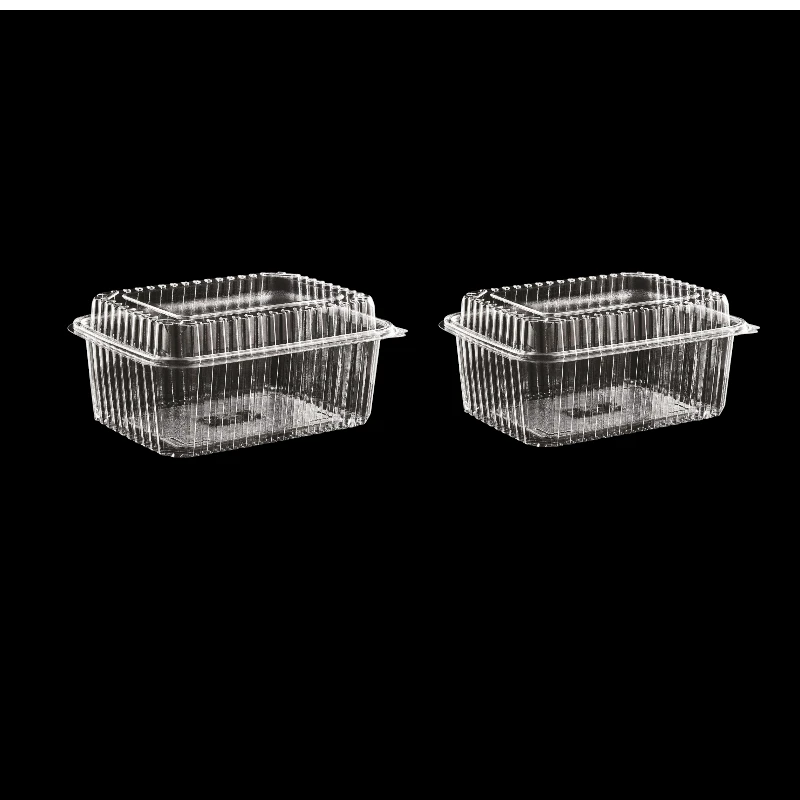

Thermoforming is one such technology that has revolutionized food packaging. It involves heating a plastic sheet to a pliable temperature, then forming it into a desired shape using molds. The process can produce a wide variety of shapes and sizes, making it ideal for packaging food in different forms, from trays to clamshell containers. Thermoforming machine for food packaging use this technology to create high-quality, custom designs that are not only functional but also aesthetically appealing. The ability to create intricate designs allows food manufacturers to offer attractive, user-friendly packaging that stands out on the shelf.

In addition to functionality and aesthetics, thermoforming machines help reduce waste by using precise amounts of material for each packaging piece. Unlike traditional methods, which may result in excess material, thermoforming machine for food packaging ensure that the packaging is perfectly molded to the food, reducing waste and contributing to sustainability. This aligns with the growing consumer preference for eco-friendly solutions. As the demand for both quality and sustainability rises, the role of advanced food packaging machines in ensuring the integrity and appeal of food products continues to expand.

Thermoforming Machine Solutions for Plastic Food Container Manufacturers

Plastic food containers are an essential part of modern food packaging, offering convenience and versatility for a wide range of food products. As food packaging companies strive to meet higher standards for quality, sustainability, and cost-efficiency, thermoforming machines are the ideal solution. These machines allow for precise control over the production process, enabling manufacturers to produce plastic packaging machines that meet specific requirements, such as durability, shape, and size. With the integration of vacuum forming technology, vacuum forming machines for food packaging provide a high degree of precision, ensuring that each container is uniformly shaped and properly sealed.

For plastic food container manufacturers, investing in advanced thermoforming machine for food packaging offers significant advantages. Not only do these machines produce high-quality containers, but they also offer flexibility, allowing manufacturers to create a variety of packaging solutions. Whether it’s a simple tray for ready-to-eat meals or a more intricate clamshell design, thermoforming equipment for food packaging allows for a wide range of designs and materials to be used. This versatility is particularly important in the food industry, where packaging needs can vary greatly depending on the product being packaged.

Food packaging machines that utilize thermoforming technology also offer long-term durability and lower operational costs. Thermoforming machine manufacturers have made significant improvements in machine efficiency, making it possible for companies to produce large volumes of packaging with minimal energy consumption. This reduction in energy usage translates into significant cost savings, making thermoforming machines a smart choice for food packaging machinery. Additionally, these machines provide high-speed production capabilities, helping manufacturers meet the increasing demand for packaged food products while maintaining the highest quality standards.

High-Efficiency Thermoforming for Food Packaging

In the fast-paced food packaging industry, high efficiency is paramount. The need for rapid production without compromising on quality is a constant challenge for packaging manufacturers. Thermoforming machines for food packaging are designed to meet these demands by offering high-speed production capabilities. The precision molding of thermoformed trays and containers ensures that the packaging process is not only quick but also reliable. This high level of efficiency is crucial for businesses that need to meet tight deadlines while maintaining product quality. With advanced features like automated loading and unloading, thermoforming equipment for food packaging significantly reduces labor costs and increases throughput.

The efficiency of thermoforming machines also extends to material use. Unlike other packaging methods, which may generate excess waste, thermoforming machines for food packaging optimize the use of plastic, creating perfectly shaped containers with minimal scrap. This material efficiency contributes to both cost savings and environmental sustainability. In addition, the vacuum forming machines for food packaging that INPAK offers use vacuum technology to reduce the need for excess material, ensuring that every container is precisely formed to fit the product, eliminating waste and contributing to a greener operation.

Moreover, the integration of advanced technology in food packaging machinery allows manufacturers to produce high-quality, consistent packaging solutions at an accelerated pace. Automated controls and improved heating and cooling systems ensure that the thermoforming machine maintains optimal performance, even during high-volume production runs. This combination of speed, precision, and cost-effectiveness makes thermoforming machines an essential tool for any business in the food packaging industry looking to maximize productivity without sacrificing quality.

Customization Options in Food Packaging with INPAK Machines

Customization is one of the key advantages of using thermoforming machines for food packaging. With the ability to produce a variety of shapes and sizes, thermoforming machines offer flexibility that allows manufacturers to create unique packaging tailored to specific food products. Whether it’s a custom-sized tray for fresh produce or a specialized container for delicate baked goods, the customization capabilities of INPAK’s food packaging machines provide endless possibilities. These machines can be adjusted to produce different container types and sizes, making them ideal for businesses that need to cater to a wide range of products.

The ability to customize packaging also extends to the materials used. Thermoforming machine manufacturers like INPAK design machines that can handle multiple types of plastic materials, including PET, PVC, and PLA. This versatility allows manufacturers to select the most suitable material for each food product, whether they prioritize sustainability, durability, or cost-efficiency. Food packaging machinery with custom settings ensures that businesses can meet the specific requirements of their clients, delivering personalized packaging solutions that enhance brand identity and appeal.

Another important aspect of customization is the ability to incorporate advanced features such as branding and labeling directly onto the packaging. Thermoforming machines for food packaging can be equipped with the technology needed to print logos, product names, and other relevant information directly onto the containers. This feature not only enhances the visual appeal of the product but also ensures that important details, such as expiration dates and ingredients, are prominently displayed. Customization options in packaging can help businesses stand out in a competitive market, and thermoforming machines provide the flexibility needed to meet these diverse needs.

Cost-Effective Food Packaging Solutions with INPAK Machines

Cost-effectiveness is a crucial factor for businesses looking to stay competitive in the food packaging industry. Thermoforming machines for food packaging offer a cost-efficient solution by reducing waste, optimizing material use, and speeding up production cycles. Food packaging machinery that uses thermoforming technology allows manufacturers to produce high-quality packaging with minimal material costs. By reducing the amount of excess plastic used in the molding process, these machines contribute to a significant reduction in operational expenses. Furthermore, the long lifespan and durability of thermoforming machines ensure that manufacturers receive a high return on investment.

The energy efficiency of thermoforming machine for food packaging also plays a role in reducing overall costs. Advanced heating systems in INPAK’s vacuum Thermoforming machine for food packaging help minimize energy consumption, ensuring that the production process remains environmentally friendly and cost-effective. Additionally, the ability to produce large volumes of packaging quickly allows businesses to meet high demand without the need for costly downtime or additional labor.

Investing in high-quality thermoforming machines also reduces the need for maintenance and repairs. The robust construction and innovative technology of INPAK’s food packaging machines mean that businesses can rely on them for long-term use, minimizing unexpected costs. With lower operating costs, reduced waste, and increased production speed, thermoforming machines offer an unbeatable combination of affordability and quality, making them an essential investment for any company in the food packaging industry.

Efficient Food Packaging Production with INPAK Thermoforming Machines

Efficiency is at the core of INPAK thermoforming machines for food packaging, which have been designed to streamline production processes and enhance productivity. By integrating automation, these machines can operate at higher speeds with less manual intervention, significantly reducing labor costs and human error. Automated systems ensure that each food packaging machine runs smoothly, creating a high-volume output of precise and consistent packaging solutions. This efficiency is particularly important in a fast-paced industry where companies must meet tight deadlines and consumer demands.

In addition to automation, thermoforming machines offer precise control over material usage. Advanced heating systems and mold designs allow for minimal waste, ensuring that every piece of plastic is used to its fullest potential. This efficiency not only saves money but also contributes to sustainability efforts, as less material waste means fewer resources are needed. The combination of speed and sustainability in INPAK’s food packaging machines makes them an ideal solution for companies looking to optimize their production lines.

Finally, the long-lasting durability of INPAK’s thermoforming machines ensures that businesses can rely on them for years of uninterrupted service. The rugged construction and innovative technology make these machines capable of handling the demands of high-volume production. With thermoforming machine manufacturers like INPAK leading the way, companies can trust that their investment in thermoforming equipment for food packaging will pay off in the form of consistent, cost-effective, and efficient production.