Leading Thermoforming Companies Providing Global Packaging Solutions

The global packaging industry is driven by innovation, efficiency, and sustainability, with thermoforming companies at the forefront of these advancements. By offering state-of-the-art thermoforming machines, these industry leaders provide solutions that meet the demands of food, medical, industrial, and consumer goods sectors. The adaptability and efficiency of plastic packaging machines have positioned them as essential assets for manufacturers worldwide. From vacuum thermoforming machines to advanced plastic thermoforming equipment, top manufacturers deliver precision, durability, and cost-efficiency.

Table of Contents

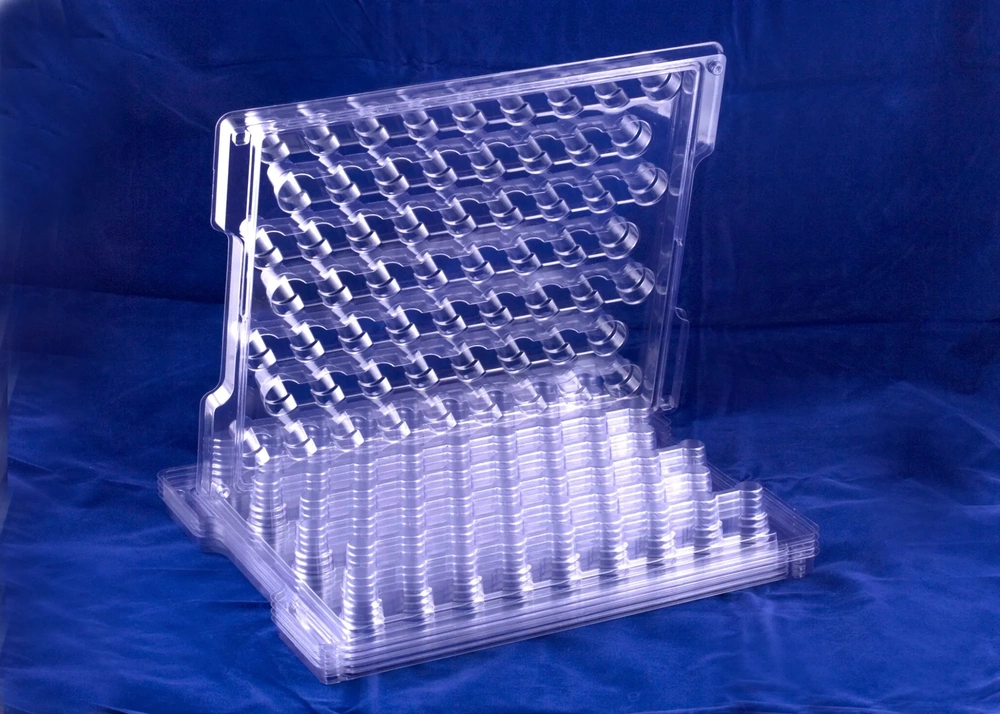

Thermoforming machine manufacturers focus on delivering scalable solutions that cater to both small and large production runs. Their thermoforming packaging solutions help businesses create high-quality products, from disposable trays to specialized containers, that meet international safety and quality standards. Many plastic thermoforming manufacturers also offer design consultation, enabling clients to customize packaging that reflects brand identity while ensuring practicality in storage and transportation.

By collaborating with trusted thermoforming machine suppliers, companies gain access to technology that improves production speed, material efficiency, and product quality. Leaders in industrial thermoforming services are not just providing equipment; they are delivering complete packaging systems tailored to industry needs. Their influence extends across the globe, providing manufacturers with competitive advantages in both cost and innovation.

What is Thermoforming? Key Benefits in Modern Packaging

Thermoforming is a manufacturing process in which a plastic sheet is heated to a pliable forming temperature, shaped to a specific mold, and then trimmed to create the final product. The process is widely used by thermoforming companies for producing items ranging from food containers to automotive components. Thermoforming machines are central to this process, enabling fast and efficient production of precise shapes and sizes. This technology has become an integral part of plastic packaging machines used in global industries.

One of the major benefits of thermoforming is its versatility. Thermoforming machine manufacturers can configure systems to work with different materials such as PET, PP, PVC, PS, and PLA. This flexibility allows thermoforming packaging solutions to meet a wide range of application needs, whether it’s for lightweight food trays or heavy-duty industrial parts. Furthermore, custom thermoformed packaging can be developed to suit unique specifications, offering enhanced brand presentation and product protection.

Cost efficiency is another defining advantage. Compared to alternative manufacturing methods, plastic thermoforming equipment often requires lower tooling costs and shorter setup times. Vacuum thermoforming machines enhance the precision of forming, ensuring minimal material waste and consistent quality. As a result, plastic thermoforming manufacturers can deliver high-quality packaging at competitive prices, making thermoforming a preferred choice for modern businesses.

Top Thermoforming Companies Worldwide: Industry Leaders

Across the globe, thermoforming companies are recognized for their ability to deliver innovative and reliable packaging technologies. Industry leaders invest heavily in research and development to advance thermoforming machine manufacturing techniques. By integrating automation, energy efficiency, and advanced heating systems, these companies maintain their competitive edge in the plastic packaging machines market.

Prominent thermoforming machine manufacturers operate in multiple countries, serving industries ranging from food packaging to aerospace. These companies offer a variety of thermoforming machines, including heavy gauge thermoforming machines for thick plastic applications and vacuum thermoforming machines for intricate designs. Many of them also provide end-to-end industrial thermoforming services, ensuring customers receive full support from machine installation to ongoing maintenance.

Plastic thermoforming manufacturers like INPAK, along with other global leaders, have set industry benchmarks in quality, durability, and sustainability. They ensure that their plastic thermoforming equipment meets international standards, making them trusted partners for multinational corporations. By offering custom thermoformed packaging, these companies help brands differentiate their products and meet specific market demands.

Innovations in Thermoforming Technology: Trends & Advancements

The latest advancements in thermoforming are transforming how thermoforming companies operate and deliver products. Modern thermoforming machines now feature servo-driven systems, precision heaters, and intelligent automation to increase production speed and accuracy. These innovations are reshaping the thermoforming machine production landscape and enhancing the capabilities of plastic packaging machines across industries.

Smart control systems have become standard among leading thermoforming machine manufacturers, allowing operators to monitor and adjust production parameters in real time. Thermoforming automation technology ensures consistency, reduces human error, and optimizes resource usage. Additionally, vacuum thermoforming machines now offer improved air evacuation and forming accuracy, which benefits applications requiring complex designs and fine detail.

The trend toward modular plastic thermoforming equipment allows manufacturers to easily upgrade or reconfigure their systems to adapt to market demands. Heavy gauge thermoforming machines are benefiting from more efficient heating systems, reducing energy consumption and operational costs. These advancements are enabling plastic thermoforming manufacturers to produce more sustainable and cost-effective thermoforming packaging solutions without sacrificing quality.

Custom Thermoforming Solutions for Diverse Industries

Thermoforming companies understand that no two industries have identical packaging requirements. As a result, they provide custom thermoformed packaging that addresses the specific needs of sectors such as food, medical, consumer goods, and industrial manufacturing. Whether it’s designing child-resistant packaging for pharmaceuticals or creating tamper-proof containers for retail, plastic thermoforming manufacturers excel in delivering tailored solutions.

For the food industry, thermoforming machines enable the production of hygienic and durable packaging, essential for maintaining product freshness. Thermoforming machine manufacturers often offer specialized molds and vacuum thermoforming machines to ensure food containers meet safety and preservation standards. Similarly, in the medical sector, plastic thermoforming equipment is used to create sterile trays and protective casings for delicate instruments.

Industrial thermoforming services cater to heavy-duty requirements, including automotive panels, equipment housings, and protective covers. By using heavy gauge thermoforming machines, manufacturers can produce thicker, more robust components. The adaptability of thermoforming packaging solutions ensures that businesses in any industry can find a custom fit for their operational needs.

Sustainability in Thermoforming: Eco-Friendly Packaging Options

Sustainability has become a critical priority for thermoforming companies, with many investing in eco-conscious materials and energy-efficient processes. Thermoforming machine manufacturing now often includes features that reduce waste, such as precision cutting and material recycling capabilities. By using biodegradable or recyclable plastics, plastic thermoforming manufacturers are contributing to greener supply chains.

Modern thermoforming machines are designed to work with environmentally friendly materials like PLA and rPET, enabling thermoforming packaging solutions that meet global sustainability standards. Vacuum thermoforming machines can optimize material usage, ensuring minimal waste without compromising quality. Many thermoforming machine suppliers also provide consultation on eco-friendly designs to help clients reduce their carbon footprint.

Through innovations in thermoforming automation technology, manufacturers can achieve energy savings and reduced operational emissions. Heavy gauge thermoforming machines with efficient heaters lower energy consumption while maintaining production output. As a result, businesses benefit from both cost savings and improved environmental performance, making custom thermoformed packaging a sustainable choice for the future.

Choosing the Right Thermoforming Machine for Your Business

Selecting the right thermoforming machine requires a thorough understanding of your production needs, materials, and budget. Thermoforming companies offer a wide range of options, from vacuum thermoforming machines for precision molding to heavy gauge thermoforming machines for robust products. When evaluating thermoforming machine suppliers, it’s important to consider their expertise in thermoforming machine manufacturing and after-sales support.

The price of a thermoforming machine can vary significantly based on features, production capacity, and automation level. Leading thermoforming machine manufacturers provide tailored advice to help businesses select the right system. Factors such as material compatibility, energy efficiency, and integration with other plastic packaging machines should also be part of the decision-making process.

Working with reputable plastic thermoforming manufacturers ensures you get high-quality equipment and reliable industrial thermoforming services. The right machine will not only meet current production goals but also provide the flexibility to adapt to future market demands. By choosing wisely, businesses can maximize the return on their investment in plastic thermoforming equipment.

Why INPAK Stands Out Among Thermoforming Companies

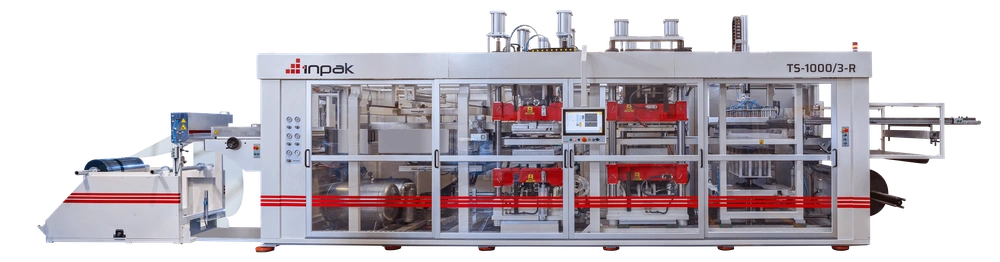

Among global thermoforming companies, INPAK has built a strong reputation for delivering innovative and reliable thermoforming machines. Specializing in thermoforming machine production, INPAK offers solutions that combine advanced automation, precision engineering, and energy efficiency. Their product line includes vacuum thermoforming machines, heavy gauge thermoforming machines, and other plastic thermoforming equipment designed for diverse applications.

INPAK’s expertise as a thermoforming machine manufacturer extends beyond equipment production. The company provides complete thermoforming packaging solutions, from machine installation to industrial thermoforming services that support ongoing operations. This commitment to customer success has positioned INPAK as a trusted partner for businesses seeking high-quality custom thermoformed packaging and durable plastic packaging machines.

What truly sets INPAK apart is its dedication to innovation and sustainability. By incorporating advanced thermoforming automation technology, they help clients increase productivity while reducing energy consumption and waste. INPAK’s tailored approach ensures that each customer receives a solution perfectly suited to their business needs, reaffirming their leadership among plastic thermoforming manufacturers worldwide.