Thermoforming Blister Packaging Machines for Durable and Attractive Product Displays

A thermoforming blister packaging machine is an essential solution for businesses seeking both product protection and visual appeal in their packaging. By heating and shaping plastic sheets into precise molds, these machines create blister packs that are strong, tamper-resistant, and visually transparent, allowing customers to see the product while ensuring it stays safe. The durability of the packaging extends shelf life and reduces the risk of damage during transportation, making it a trusted choice in retail, electronics, medical, and consumer goods industries.

Table of Contents

The appeal of products packaged with a thermoforming blister packaging machine lies in the combination of robust protection and clear presentation. Consumers can view the product directly through the transparent blister, which builds trust and encourages purchasing decisions. Paired with vibrant printed cards or inserts, these packs can highlight brand identity and product features effectively. Modern thermoform packaging equipment allows for customization in shape, size, and design, enabling businesses to create packaging that aligns with their branding strategy.

In today’s competitive retail environment, packaging is not just about containment—it’s a marketing asset. A thermoforming blister packaging machine helps businesses produce high-quality, attractive packaging that stands out on store shelves. Whether using a high-speed Thermoforming machines for mass production or custom blister packaging solutions for niche products, companies can achieve packaging that delivers both durability and a premium look, ensuring products make a lasting impression on consumers.

What is a Thermoforming Blister Packaging Machine?

A thermoforming blister packaging machine is a specialized type of thermoform packaging equipment designed to create durable, transparent, and precise packaging for a wide range of products. These machines use heat and pressure to mold plastic sheets into custom shapes, forming a protective cavity, or “blister,” that securely holds products in place. The process involves heating a plastic film, forming it into the desired shape, trimming it to size, and sealing it with a backing material such as paperboard, foil, or another plastic sheet. Whether for consumer goods, electronics, pharmaceuticals, or tools, these machines deliver packaging that protects products and enhances their presentation.

The rise of automatic thermoforming machines has transformed the packaging industry, making blister packs faster to produce and more consistent in quality. They are widely used by manufacturers seeking both functional protection and strong visual appeal for their products. A blister packaging machine manufacturer typically designs these machines to handle multiple materials, such as PVC, PET, and other thermoformable plastics, enabling flexibility for different industries. The forming, sealing, and cutting processes are automated, reducing labor costs and ensuring uniformity.

Unlike traditional packaging methods, plastic thermoforming machines allow businesses to customize shapes and features for each product line. The transparency of blister packaging means consumers can see the actual product, increasing trust and purchase likelihood. For high-demand industries where both efficiency and appearance are crucial, thermoforming blister packaging machines are an ideal choice that balances protection with aesthetics.

Key Benefits of Using Thermoform Packaging Machines

The primary advantage of a thermoforming blister packaging machine is its ability to produce secure, tamper-evident packaging. This not only safeguards the product from physical damage but also protects it from environmental factors like moisture and dust. In sectors such as electronics or pharmaceuticals, these protective qualities are essential to maintaining product integrity. By using thermoform packaging equipment, manufacturers can reduce returns and complaints, enhancing their brand reputation.

Another benefit is cost efficiency, especially when operating a high-speed thermoforming machine. The automation capabilities minimize manual handling and speed up production cycles, enabling companies to meet high-volume demands without sacrificing quality. By investing in industrial thermoforming equipment, businesses can achieve lower cost-per-unit packaging, which is particularly advantageous for large-scale operations.

In addition, custom blister packaging solutions allow brands to differentiate themselves on store shelves. The ability to create unique shapes, sizes, and branding directly into the packaging design helps products stand out. A vacuum forming packaging machine can create deep-draw designs for bulkier items, while a PVC blister packaging machine can produce crystal-clear, glossy finishes for premium product presentation. These benefits combine to create packaging that is both functional and visually compelling.

Types of Thermoforming Machines for Different Industries

Different industries require specific types of thermoforming blister packaging machines to meet their unique product and regulatory requirements. For example, in the medical and pharmaceutical sector, machines must comply with stringent hygiene standards and produce packaging that can withstand sterilization processes. A blister packaging machine manufacturer catering to this market often incorporates advanced controls, cleanroom compatibility, and precise forming capabilities into their designs.

For consumer electronics and hardware tools, a plastic thermoforming machine with strong sealing capabilities ensures that heavy or irregularly shaped products remain secure during shipping and handling. These machines may integrate vacuum forming packaging machine technology for deep cavities or automatic thermoforming machines for high-volume output. The type of plastic used, such as PET or PVC, is chosen based on the desired clarity and durability.

Food and beverage industries often use thermoform packaging equipment to produce clear, safe, and tamper-proof packages that extend shelf life. A PVC blister packaging machine or PET-based system can be used for attractive displays while maintaining freshness. Whether producing packs for medical devices, snacks, batteries, or cosmetics, the versatility of industrial thermoforming equipment means each industry can tailor its choice to match both functional needs and brand presentation.

How Thermoforming Blister Packaging Enhances Product Appeal

The most noticeable advantage of thermoforming blister packaging machines is the visual appeal they bring to products. Transparent packaging lets customers inspect the product without opening it, increasing confidence and perceived value. A plastic thermoforming machine can create sleek, contoured packaging that mirrors the product’s shape, giving it a premium look.

For retailers, products packaged using thermoform packaging equipment tend to sell faster because they stand out on shelves. The clarity, gloss, and form-fitting design communicate quality, while the tamper-evident seal assures consumers of product safety. Custom blister packaging solutions can incorporate branding elements such as embossed logos or printed inserts, making the packaging an extension of the product’s marketing.

In industries with strong competition, such as consumer electronics, toys, or cosmetics, a high-speed thermoforming machine enables brands to launch products quickly while maintaining high presentation standards. The PVC blister packaging machine offers superior clarity, while vacuum forming packaging machines can produce unique shapes that attract attention. Combined, these technologies enhance the customer’s first impression, which is critical in driving sales.

Choosing the Right Thermoform Machine for Your Business

Selecting the right thermoforming blister packaging machine starts with understanding your product’s specific needs. Factors such as size, shape, material compatibility, and production volume determine the type of thermoform packaging equipment you should invest in. A blister packaging machine manufacturer can guide you through these considerations, ensuring you get the right balance between performance and cost.

For high-volume operations, an automatic thermoforming machine or high-speed thermoforming machine is ideal, reducing cycle times and increasing output. These models often include advanced controls for precision forming, cutting, and sealing. In contrast, small-to-medium enterprises might opt for versatile plastic thermoforming machines that handle multiple product lines with quick changeover capabilities.

Material choice also plays a role in the selection process. For clear, premium displays, a PVC blister packaging machine might be the best choice, while for deep cavities and complex shapes, a vacuum forming packaging machine could be more suitable. Industrial thermoforming equipment that offers flexibility and customizability will ensure your investment continues to serve your needs as your product lines evolve.

Automation and Efficiency in Thermoforming Packaging Solutions

Modern thermoforming blister packaging machines integrate automation features that drastically improve production efficiency. Automated material feeding, heating, forming, sealing, and cutting minimize manual labor, reducing human error and downtime. This level of automation in thermoform packaging equipment means faster turnaround times and consistent quality across thousands of units.

Using an automatic thermoforming machine allows operators to program parameters for each product type, ensuring repeatability and precision. High-speed thermoforming machines can produce large batches in record time, meeting urgent orders without compromising accuracy. For industries facing tight deadlines and seasonal spikes, this efficiency is invaluable.

In addition to speed, industrial thermoforming equipment often includes energy-efficient heating systems, servo-driven motion control, and remote monitoring capabilities. Whether using a PVC blister packaging machine for retail goods or a vacuum forming packaging machine for specialty items, automation reduces waste, lowers costs, and boosts overall productivity while maintaining top-tier packaging quality.

Customizable Thermoforming Solutions for Unique Product Displays

One of the strengths of thermoforming blister packaging machines is their adaptability to custom designs. Custom blister packaging solutions can be tailored to fit the exact contours of a product, providing a secure hold and an appealing shape. With plastic thermoforming machines, brands can experiment with different materials, finishes, and thicknesses to achieve their desired look and feel.

For products with unique geometries, a vacuum forming packaging machine can create deep or unusual cavities without compromising clarity or strength. The flexibility of thermoform packaging equipment ensures that even unconventional products can have professional, attractive packaging. By integrating brand colors, printed backings, and embossed logos, companies can create memorable unboxing experiences.

A blister packaging machine manufacturer with experience in industrial thermoforming equipment can offer advanced design services, helping translate marketing visions into practical, manufacturable packaging. Whether using a PVC blister packaging machine for clarity or a hybrid forming system for textured finishes, the customization potential supports brand differentiation and product recognition.

Sustainable Packaging with Thermoforming Technology

Sustainability is becoming a central concern in packaging design, and thermoforming blister packaging machines are adapting to meet these demands. Many modern plastic thermoforming machines can process recyclable or biodegradable materials such as PET, RPET, or PLA. This allows brands to maintain the benefits of thermoform packaging equipment while reducing environmental impact.

By optimizing material thickness and improving sealing techniques, automatic thermoforming machines can reduce waste without sacrificing strength or durability. The efficiency of high-speed thermoforming machines also minimizes energy consumption per unit, further lowering the carbon footprint. Industrial thermoforming equipment can be fine-tuned to handle thinner gauges, reducing resource use while maintaining protective qualities.

A forward-thinking blister packaging machine manufacturer will offer custom blister packaging solutions that incorporate eco-friendly materials and processes. From PVC blister packaging machines adapted for recyclable alternatives to vacuum forming packaging machines that reduce off-cuts, thermoforming technology supports a greener approach to product presentation without compromising quality or appeal.

Global Trends in Thermoform Packaging Machinery

Globally, demand for thermoforming blister packaging machines is rising, driven by the need for attractive, protective, and cost-effective packaging solutions. Advances in thermoform packaging equipment include improved heating technology, faster cycle times, and digital controls for enhanced precision. The market is also seeing a surge in automatic thermoforming machines that integrate AI for predictive maintenance and quality monitoring.

Another trend is the increasing adoption of custom blister packaging solutions for niche markets such as luxury goods, premium electronics, and specialized tools. High-speed thermoforming machines are enabling manufacturers to meet fast-changing consumer demands without excessive inventory buildup. Additionally, vacuum forming packaging machines are gaining popularity for their versatility in creating complex shapes.

Environmental considerations are also shaping trends, with blister packaging machine manufacturers investing in industrial thermoforming equipment that supports recyclable materials. The shift away from single-use plastics toward sustainable options is influencing even PVC blister packaging machines, as manufacturers adapt to work with alternative films that maintain clarity and durability.

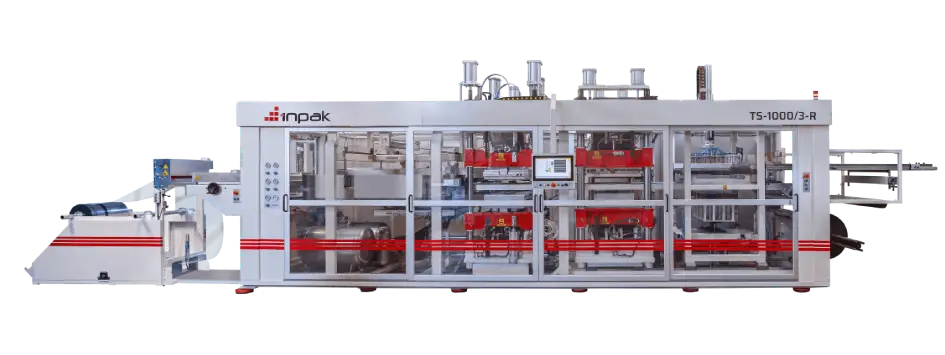

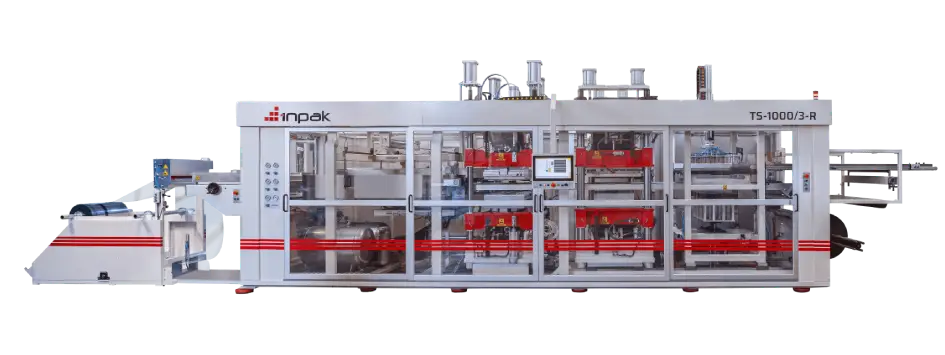

Why Choose INPAK for High-Quality Thermoforming Machines?

When it comes to thermoforming blister packaging machines, INPAK stands out as a trusted provider of reliable, efficient, and customizable solutions. As a seasoned blister packaging machine manufacturer, INPAK combines advanced engineering with deep industry knowledge to deliver thermoform packaging equipment that meets the highest standards of quality and performance.

INPAK’s range includes automatic thermoforming machines, high-speed thermoforming machines, and industrial thermoforming equipment capable of handling a variety of materials, including PVC, PET, and eco-friendly alternatives. Whether you need a vacuum forming packaging machine for specialty products or a PVC blister packaging machine for high-clarity displays, INPAK offers solutions tailored to your business needs. Their expertise ensures precise forming, secure sealing, and efficient production.

By choosing INPAK, you gain access to custom blister packaging solutions that enhance product appeal and protect goods throughout the supply chain. With a commitment to innovation, sustainability, and customer support, INPAK provides plastic thermoforming machines that keep your packaging operations competitive in a rapidly evolving market.