INPAK Thermoformed Food Packaging for Safe and Reliable Use

Thermoformed food packaging has emerged as a crucial element in ensuring the safety, hygiene, and quality preservation of food products during storage, transport, and display. This packaging method uses thermoforming technology to create custom-shaped plastic containers and trays that perfectly fit various food items, ranging from fresh produce to ready-to-eat meals. The precision and reliability of thermoformed plastic food packaging guarantee minimal contamination risks and longer shelf life, meeting both consumer expectations and regulatory standards.

Table of Contents

One of the significant benefits of thermoformed food packaging is its adaptability to different shapes and sizes, which helps manufacturers optimize product presentation while maintaining functionality. It allows the packaging to be lightweight yet sturdy, reducing material waste and shipping costs. These packages often include features such as venting holes or secure sealing options to maintain product freshness and prevent spoilage.

In addition to food safety, custom thermoformed food packaging also plays an important role in brand differentiation. Businesses can create uniquely designed packaging tailored to their product specifications and market demands. INPAK, a leading name in thermoforming machine manufacturing, supports this trend by offering innovative machines that enable fast and efficient production of high-quality food packaging solutions.

INPAK Thermoformed Food Packaging for Safe and Reliable Use

What is Thermoformed Food Packaging and How Does It Work?

Thermoformed food packaging refers to plastic containers, trays, and packages formed through the thermoforming process—an advanced manufacturing method where a plastic sheet is heated to a pliable forming temperature, shaped into a specific mold, and trimmed to create a usable product. The process enables precise shaping for packaging various food items such as meats, dairy, ready meals, and produce. It provides reliable barrier properties and structural integrity, helping preserve freshness and protect products during transportation and storage.

In the thermoforming machine for food packaging, the plastic sheet is loaded, heated, and vacuum-formed over a mold to produce the desired shape. After forming, the material is cooled and trimmed automatically, resulting in custom-shaped packaging tailored to specific products. This method is suitable for both rigid and flexible packaging formats, offering flexibility for different food types and packaging presentations. With the help of plastic packaging machines, manufacturers can produce large volumes of high-quality containers efficiently.

The advantages of thermoformed plastic food packaging go beyond its functional design. It provides a lightweight yet strong alternative to other packaging materials such as metal or glass. Additionally, its transparency allows clear product visibility, which is highly desirable in retail. The process is also compatible with various materials that can be recycled or made from bio-based polymers, making it a more sustainable packaging option for environmentally conscious companies.

Materials Used in Thermoformed Food Packaging

The selection of materials is crucial in thermoformed food packaging, as different foods require different protective qualities. Common materials include PET (Polyethylene Terephthalate), which is valued for its strength and clarity, and CPET (Crystallized PET), which offers higher temperature resistance for ready meals and ovenable trays. PP (Polypropylene) is used for microwaveable applications due to its thermal resistance and flexibility, while PS (Polystyrene) is favored for its rigidity and low cost.

Eco-conscious brands are increasingly turning to PLA (Polylactic Acid), a biodegradable and compostable plastic derived from renewable resources such as corn starch. OPS (Oriented Polystyrene) is another option that offers good clarity and strength for lightweight packaging. The compatibility of these materials with thermoforming food packaging machines allows businesses to cater to diverse market demands, from frozen meals to fresh produce.

The versatility of thermoforming machines in processing multiple material types ensures packaging that aligns with food safety standards, durability, and sustainability. Material properties such as gas and moisture barrier strength, thermal stability, and recyclability must be carefully evaluated before selecting a substrate. By integrating cutting-edge thermoforming machine production technologies, INPAK enables clients to work with a broad range of materials for tailored food packaging solutions.

INPAK Thermoformed Food Packaging for Safe and Reliable Use

Key Advantages of Thermoformed Packaging in the Food Industry

One of the primary benefits of thermoformed food packaging is its ability to maintain food safety and freshness. The secure sealing properties and barrier features prevent contamination, reduce oxygen exposure, and enhance shelf life. These advantages make it a preferred choice for perishable products, improving hygiene and regulatory compliance in food handling and distribution processes.

Another advantage is the cost-effectiveness of the packaging process. Thermoforming machine manufacturing allows for mass production of packaging with minimal material waste. Thin plastic sheets are used efficiently, and the ability to stack trays helps reduce transportation and storage costs. This makes thermoformed packaging a practical solution for businesses seeking to optimize operational efficiency without sacrificing quality.

Additionally, custom thermoformed food packaging offers high visual appeal and brand differentiation. With precise molding, companies can design packaging with unique shapes, logos, and compartments tailored to specific food types. This customization helps products stand out on retail shelves and meet consumer preferences for functional and aesthetically pleasing packaging.

Types of Thermoformed Trays: Applications and Industry Usage

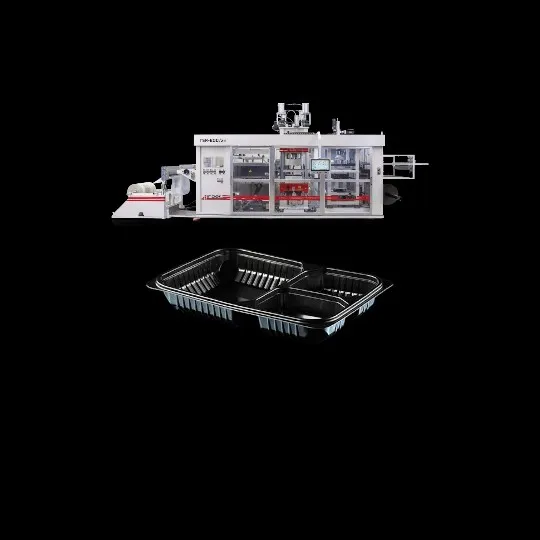

Thermoformed trays are categorized based on their structure, application, and material. Rigid trays, commonly made from CPET or PP, are used for ovenable or microwave-ready meals. Flexible or semi-rigid trays are typically used for packaging cold cuts, snacks, or produce. These trays are widely used in the food sector, particularly in meat processing, dairy packaging, bakery products, and convenience foods.

Another important application is compartmentalized trays, which are designed with separate sections for meal components. These are ideal for ready-to-eat meals or airline catering where food separation is crucial for presentation and functionality. With custom thermoformed food packaging, these trays can be tailored for specific portion sizes, shapes, and branding.

The use of thermoforming machines ensures consistent quality and precision in tray manufacturing. INPAK’s systems provide seamless integration from heating and forming to trimming and stacking. This makes thermoforming machine suppliers an essential partner for food companies needing reliable packaging performance across various tray designs and applications.

INPAK Thermoformed Food Packaging for Safe and Reliable Use

Thermoforming Machines: The Core of Food Packaging

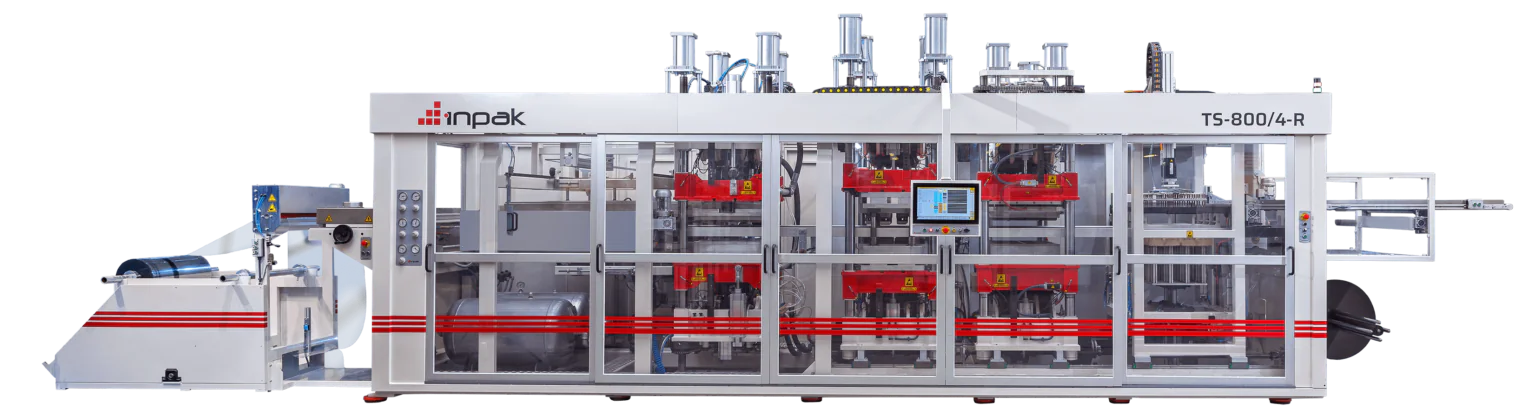

Thermoforming machines play a pivotal role in the production of food packaging by automating the shaping and cutting of plastic sheets into functional packaging products. These machines operate with high-speed precision, ensuring uniformity and quality in every unit. They are equipped with advanced features like servo-driven motion control, intelligent heating zones, and automated stacking systems.

The efficiency of food packaging machines significantly boosts productivity by minimizing downtime and optimizing cycle times. With real-time monitoring and remote access features, modern thermoforming machine manufacturers like INPAK provide machines that ensure uninterrupted production and quick troubleshooting. This reliability is vital for food packaging businesses with high-volume requirements.

Furthermore, the integration of vacuum and pressure forming technologies allows for the creation of detailed shapes and complex geometries. These capabilities are essential for thermoformed plastic food packaging, enabling food producers to maintain quality and product integrity throughout the supply chain. The precision and versatility of INPAK’s machines empower manufacturers to meet evolving consumer expectations.

Choosing the Right Thermoforming Machine for Your Production Needs

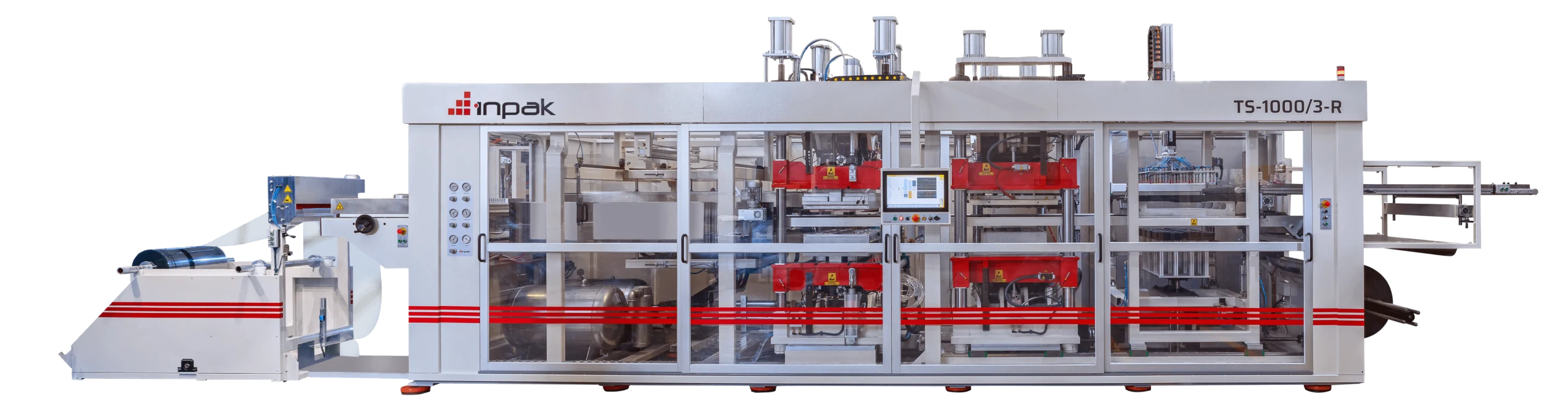

Selecting the ideal machine involves evaluating your specific production requirements, including volume, packaging formats, material types, and available space. INPAK offers a range of machines such as the TSR-800, TS-800, and TS-1000, each tailored to different levels of output and customization. For businesses focused on hygienic packaging of fresh and processed foods, a dedicated thermoforming machine for food packaging is crucial.

Cost is another critical factor. While upfront investment is necessary, the vacuum forming machine price should be weighed against long-term gains in efficiency and reduced labor costs. Features like automatic lubrication, remote diagnostics, and servo-controlled components contribute to minimal maintenance and maximum uptime, making INPAK’s systems a cost-effective choice.

Material compatibility also matters. Ensure your thermoforming machines support the substrates you plan to use, whether it’s PET, CPET, or biodegradable options like PLA. Machines should also allow for quick mold changes and adjustable settings to accommodate different product sizes. INPAK’s expertise ensures your selected machine aligns with both present and future needs.

Why INPAK Machines Are Ideal for Food Packaging Applications

INPAK’s reputation as a leading thermoforming machine supplier stems from its commitment to innovation, quality, and customer satisfaction. Their machines are designed with advanced human-machine interfaces, enabling intuitive control and precise adjustments. Built-in safety features and robust construction further ensure long-term reliability in demanding food packaging environments.

With a focus on sustainability, INPAK’s machines are engineered for energy efficiency and material optimization. The modular design allows for customization, supporting both custom thermoformed food packaging and high-volume production. INPAK’s R&D team continuously innovates to ensure machines meet the latest food safety standards and regulatory requirements.

Moreover, INPAK provides end-to-end support—from machine selection and installation to training and maintenance. Their team works closely with clients to understand specific packaging goals, ensuring that the selected thermoforming food packaging machine maximizes performance and ROI. This customer-centric approach makes INPAK a trusted partner in the global food packaging industry.

INPAK Thermoformed Food Packaging for Safe and Reliable Use

Discover INPAK’s Advanced Thermoforming Machines for High-Performance Food Packaging Production

INPAK offers a complete lineup of thermoforming machines designed to transform your food packaging process. Whether you’re producing rigid trays for ready meals or flexible containers for snacks, INPAK machines deliver precision, speed, and reliability. Models like the TS-800 and TS-850 are built to handle high production volumes with minimal waste and downtime.

The integration of features such as servo-driven transport chains, automated stacking systems, and remote diagnostics enhances operational control and performance. These machines ensure consistent results, making them suitable for both small-scale producers and large-scale manufacturers looking to scale their output. With thermoforming machine production expertise, INPAK helps streamline workflows and boost productivity.

As one of the leading thermoforming machine manufacturers, INPAK combines technical excellence with a deep understanding of the food industry’s demands. Their advanced plastic packaging machines not only meet current market needs but are also adaptable for future innovations. Investing in an INPAK system means equipping your business with a solution that ensures safe, efficient, and customizable food packaging production.