Thermoform Plastic Packaging for High-Volume and Hygienic Production

Thermoform plastic packaging is a highly efficient solution for businesses requiring large-scale, hygienic production. By utilizing thermoforming machines, manufacturers can produce vast quantities of consistent, high-quality packaging in a relatively short time. The process involves heating plastic sheets such as PET, PVC, PP, or PLA until they are pliable, then forming them over precision-engineered molds to create the desired shapes. This method ensures that each piece of packaging meets exact specifications, making it ideal for high-volume operations where uniformity and speed are critical.

Table of Contents

In addition to efficiency, thermoform plastic packaging excels in maintaining hygiene standards, which is essential in the food, medical, and pharmaceutical industries. The design of modern thermoforming machines minimizes human contact during production, reducing the risk of contamination. Automated handling, sealing, and trimming systems integrated into food packaging machines and industrial thermoforming equipment ensure that packaged products remain safe, sterile, and ready for consumer use. Medical thermoform blister packs benefit from this controlled environment, ensuring strict compliance with health regulations.

Another advantage of thermoform plastic packaging in high-volume production is its flexibility and customization. Businesses can produce a variety of packaging types—from clamshells and trays to blister packs and lids—using custom thermoformed packaging solutions. By selecting appropriate materials and mold designs, manufacturers can optimize packaging strength, appearance, and sustainability. With the support of experienced thermoforming machine manufacturers and suppliers, companies can achieve scalable production without compromising quality, hygiene, or efficiency, making thermoform plastic packaging an essential choice for modern manufacturing.

What is Thermoform Plastic Packaging?

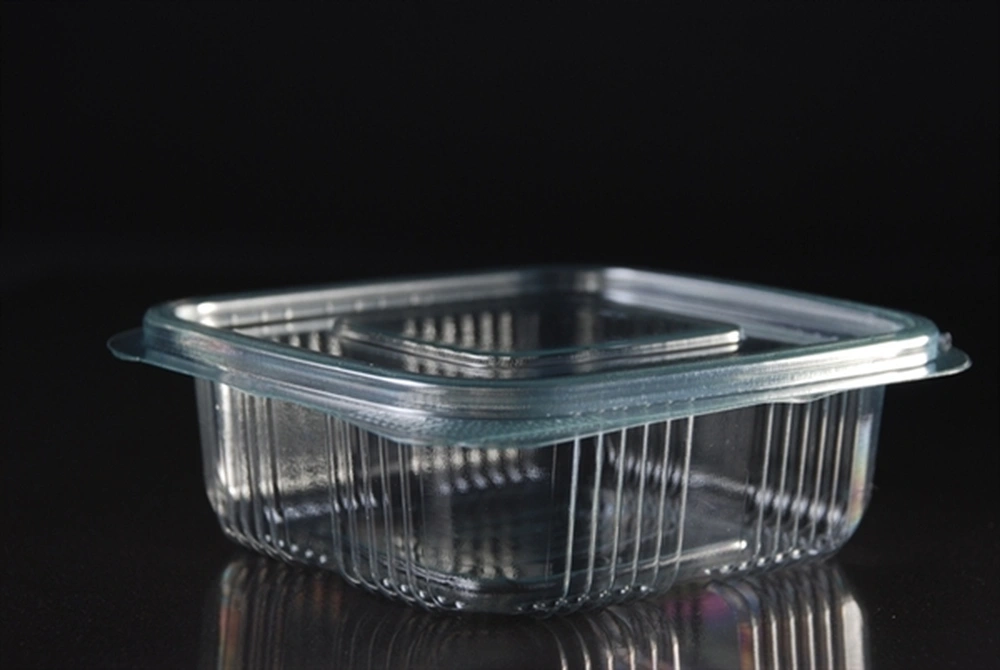

Thermoform plastic packaging is a manufacturing process where sheets of plastic are heated until pliable and then formed into specific shapes using molds. This method allows the production of high-quality packaging that is lightweight yet durable, meeting both aesthetic and functional requirements. From simple trays to complex blister packs, thermoform plastic packaging serves industries ranging from food and medical products to consumer goods and electronics.

The process involves the use of Thermoforming machines which are engineered to handle different plastic materials, including PET, PVC, PP, and PS. Modern plastic packaging machines utilize precision heating, vacuum forming, and pressure forming techniques to ensure consistent product quality. Thermoforming machine production has advanced significantly, enabling manufacturers to produce high volumes efficiently while maintaining strict quality standards.

A key advantage of thermoform plastic packaging is its flexibility. Custom designs are easily achievable, and adjustments to molds or sheet thicknesses allow for rapid changes in production. Thermoforming machine manufacturers continue to innovate, offering solutions that cater to both standard and complex packaging requirements. This versatility makes thermoform plastic packaging a preferred choice for industries aiming to balance production efficiency with high-quality presentation.

Key Applications of Thermoform Packaging

Thermoform plastic packaging has extensive applications across multiple industries due to its adaptability and durability. In the food sector, it is widely used for ready meals, trays, and portion control packaging, ensuring products remain fresh and visually appealing. Food packaging machines are often integrated with thermoforming machines to create packaging that meets strict safety and hygiene standards.

Medical applications also rely heavily on thermoform plastic packaging, particularly for medical thermoform blister packs and sterile container solutions. The precision and reliability of thermoforming machine manufacturers ensure that medical products are securely packaged, protecting them from contamination while maintaining compliance with regulatory standards. In addition, industrial thermoforming equipment is used to create protective housings, packaging for fragile electronics, and custom inserts, showcasing the versatility of thermoform plastic packaging.

Another critical application is in pharmaceuticals, where thermoform packaging for pharmaceuticals ensures tamper-proof, safe, and efficient distribution. Custom thermoformed packaging solutions allow companies to optimize shelf presence and logistics. High-speed vacuum thermoforming machines and pressure forming machines are employed to handle large volumes without compromising quality, making thermoform plastic packaging indispensable for modern manufacturing needs.

Advantages of Thermoforming for High-Volume Production

High-volume production demands efficiency, consistency, and minimal waste, all of which are delivered by thermoform plastic packaging. With advanced thermoforming machines, manufacturers can produce thousands of units per hour, ensuring that large-scale operations meet tight deadlines without sacrificing quality. High-speed thermoforming machines streamline the process while maintaining precise control over sheet thickness and mold details.

Thermoforming machine manufacturing incorporates automated systems, enabling continuous production with minimal human intervention. Automated plastic packaging machines reduce labor costs and errors, ensuring that products are uniform and compliant with industry standards. Thermoforming machine suppliers focus on producing equipment capable of handling both thin-gauge and thick-gauge materials, allowing flexibility in packaging types without slowing production.

Moreover, thermoform plastic packaging supports customization while maintaining speed. Whether producing food-grade thermoform packaging or industrial packaging solutions, manufacturers can quickly adapt to changes in design or volume. The ability to integrate custom thermoformed packaging with automated systems ensures that even high-volume production remains efficient, cost-effective, and reliable.

Hygienic Design: Why Thermoform Packaging is Ideal

Hygiene is critical in sectors such as food, pharmaceuticals, and medical devices, making thermoform plastic packaging an optimal solution. Its smooth surfaces and tight seals minimize contamination risks, and high-quality thermoforming machines allow precise control over temperature and forming processes to maintain sterility. Hygienic plastic packaging solutions are essential for maintaining product integrity and consumer safety.

Thermoforming machine manufacturers design equipment with easy-to-clean surfaces, enclosed production areas, and materials that withstand rigorous sanitation protocols. This ensures compliance with food safety standards and pharmaceutical regulations. Food packaging machines and industrial thermoforming equipment equipped for hygienic production are vital for businesses that prioritize product safety while still producing at high volume.

The adaptability of thermoform plastic packaging also supports the creation of medical thermoform blister packs, which protect sensitive products from external contamination. High-speed thermoforming machine production ensures that these hygienic packages are manufactured efficiently without compromising quality. The combination of precision machinery and thoughtful design makes thermoform plastic packaging ideal for applications demanding strict hygiene standards.

Choosing the Right Thermoform Machine for Your Needs

Selecting the appropriate thermoforming machine is crucial for achieving efficiency, quality, and cost-effectiveness in thermoform plastic packaging. Factors such as production volume, material type, and product complexity influence the choice of plastic packaging machines. Leading thermoforming machine suppliers provide guidance on selecting equipment that balances these factors with budgetary considerations.

Modern thermoforming machine manufacturers offer machines capable of vacuum thermoforming or pressure forming, catering to thin-gauge and thick-gauge applications. Understanding the difference between thin-gauge vs. thick-gauge thermoforming is essential, as it affects production speed, material cost, and final product durability. Thermoform mold design also plays a pivotal role in determining machine compatibility and product quality.

Additionally, automation and integration capabilities are key. High-speed thermoforming machines equipped with robotic loading, stacking, and quality control systems enable continuous operation with minimal downtime. By consulting thermoforming machine manufacturers or checking thermoforming machine price ranges, businesses can identify the optimal solution for their production needs while ensuring flexibility for future packaging innovations.

Sustainable Thermoform Packaging Solutions

Sustainability is increasingly important in modern manufacturing, and thermoform plastic packaging offers multiple eco-friendly options. Materials such as recyclable thermoform plastics reduce environmental impact while maintaining the durability and hygiene necessary for food-grade thermoform packaging. PET thermoforming and PVC thermoforming are common choices, with manufacturers increasingly adopting biodegradable or post-consumer recycled plastics.

Thermoforming machine manufacturing now emphasizes energy efficiency and waste reduction, with advanced thermoforming machines designed to minimize material scrap. Automated systems optimize sheet usage, and high-speed thermoforming machines can reduce energy consumption per unit produced. Choosing sustainable thermoform packaging aligns with corporate responsibility initiatives and consumer demand for environmentally friendly products.

Custom thermoformed packaging also supports sustainability by reducing excess packaging and enabling multi-use solutions. Companies producing industrial thermoforming equipment and food packaging machines can leverage advanced design and material selection to create packaging that meets regulatory sustainability goals. Integrating automated thermoforming systems ensures that production efficiency is maintained while adopting greener practices, establishing thermoform plastic packaging as both practical and environmentally conscious.

INPAK: Your Trusted Partner in Thermoform Packaging Solutions

INPAK stands out as a leading provider of thermoform plastic packaging solutions, delivering high-quality thermoforming machines to meet the demands of diverse industries. With expertise in thermoforming machine production, INPAK combines innovative technology with practical design to optimize efficiency, hygiene, and product quality. Companies seeking plastic packaging machines can rely on INPAK for reliable, high-speed, and precise equipment.

INPAK’s product range includes machines for medical thermoform blister packs, food-grade thermoform packaging, and industrial thermoforming equipment, ensuring solutions for various sectors. Their emphasis on custom thermoformed packaging allows businesses to create packaging that aligns with branding, functionality, and sustainability objectives. As a trusted thermoforming machine supplier, INPAK provides support throughout the production lifecycle, from initial consultation to installation and maintenance.

By integrating advanced technologies like vacuum thermoforming machines, pressure forming machines, and automated systems, INPAK enables high-volume, hygienic, and cost-effective thermoform plastic packaging production. Their commitment to sustainable thermoform packaging ensures that clients can meet environmental standards without compromising quality. INPAK continues to be a top choice for businesses seeking the best thermoform packaging supplier, offering a comprehensive approach to modern packaging challenges.