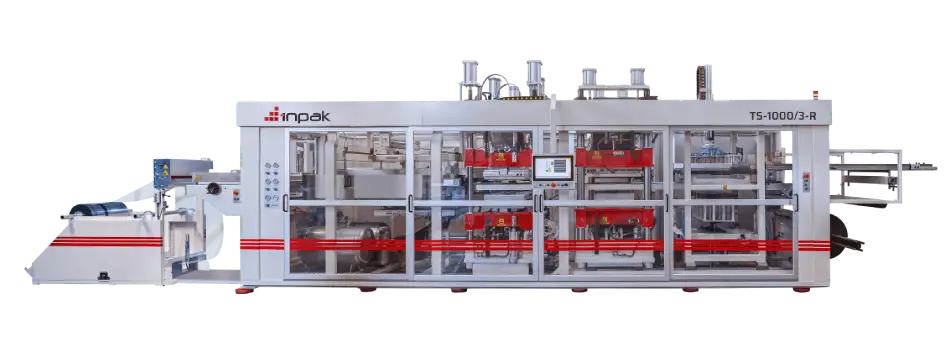

Thermoform Packaging Solutions Backed by INPAK Expertise

Thermoform packaging has emerged as a reliable and efficient solution for many industries, particularly in the plastic packaging sector. This technology involves the process of heating plastic sheets until they are soft and then molding them into specific shapes using a mold. Thermoform packaging is incredibly versatile, catering to diverse needs across food, medical, and industrial sectors. INPAK, a leader in providing thermoforming packaging solutions, offers state-of-the-art machinery designed to revolutionize the production of plastic thermoforming packaging. With a deep understanding of the market and years of experience, INPAK’s machines are at the forefront of sustainable packaging innovation.

Table of Contents

At INPAK, the focus is on delivering high-quality, efficient, and cost-effective thermoforming machines that meet the varying demands of businesses. The company provides comprehensive solutions for plastic packaging machines, helping manufacturers produce durable and aesthetic packaging for a wide range of products. These thermoforming machines not only deliver precision but also enhance production capabilities by streamlining processes. Businesses looking to create packaging that can withstand various challenges while being eco-friendly can rely on INPAK’s advanced thermoforming machine solutions to meet their needs.

The versatility of thermoform packaging has made it indispensable for industries that require durable and high-performance packaging. From food packaging to medical applications, thermoforming packaging ensures that products are not only secure but also have an appealing presentation. INPAK continues to push the boundaries of innovation, offering machines that can handle different materials, including PET, CPET, and PLA. By selecting INPAK’s thermoforming machines, manufacturers can offer their customers sustainable and functional packaging options that reduce environmental impact while improving operational efficiency.

What is Thermoform Packaging?

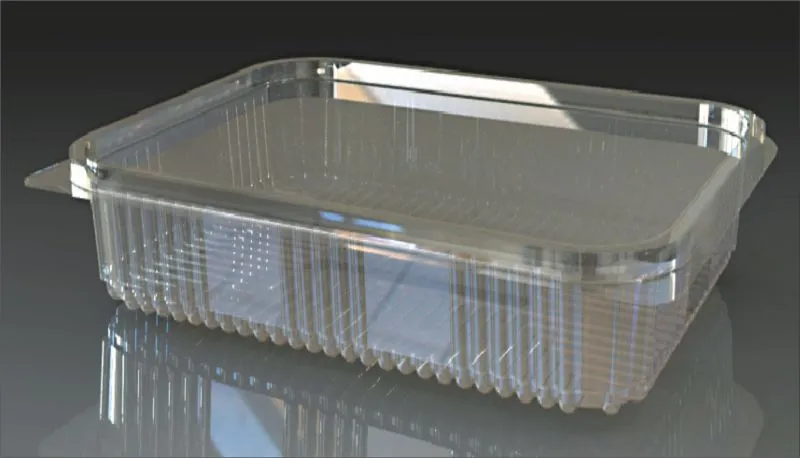

Thermoform packaging refers to the process of creating packaging products from thermoplastic sheets. These sheets are heated until they become pliable and are then molded into the desired shape using a mold or die. The process typically involves vacuum forming, where air is evacuated from the mold to ensure a perfect fit, or pressure forming, which uses air pressure to achieve a higher level of detail in the product. Thermoform packaging is widely used in food, medical, and consumer goods industries due to its durability, lightweight nature, and cost-effectiveness.

The primary benefits of thermoform packaging are its versatility and customization. With the right equipment, manufacturers can create packaging solutions that cater to specific needs, such as portioned food containers, blister packs for consumer goods, and even medical trays. Thermoforming machines are integral to producing such packaging efficiently and consistently. The thermoforming machine can adapt to various materials, ensuring that manufacturers can create packaging that is both practical and visually appealing, from food trays to clamshell packaging for electronics or small consumer products.

Moreover, thermoform packaging offers an eco-friendly alternative to traditional packaging. As more businesses seek sustainable solutions, plastic thermoforming packaging can be made from recyclable materials, reducing environmental impact. INPAK’s thermoforming machines support the use of recyclable plastics such as PET, which can be reused after use, making it an attractive option for businesses committed to sustainability. The ability to customize the design and functionality of packaging further enhances its appeal in various industries.

What Can Be Made with a Thermoforming Machine?

Thermoforming machines are incredibly versatile tools capable of producing a wide range of packaging products. In the food industry, these machines are used to create food packaging machines such as trays, clamshell containers, and protective covers for items like fruits, meats, and ready-to-eat meals. The machines are designed to work with a variety of materials such as PET, PVC, PP, and PLA, allowing manufacturers to choose the best material for their products. These thermoforming machines enable the production of highly durable, hygienic, and visually appealing packaging solutions that meet industry standards.

Aside from food packaging, thermoforming machines are also extensively used in the medical industry. They can be used to create plastic thermoforming packaging for medical devices, instruments, and sterile packaging. The precision and consistency offered by these machines ensure that each product is perfectly molded to meet safety and hygiene standards. INPAK’s thermoforming machine solutions are ideal for manufacturers looking to create high-quality medical packaging that maintains the integrity and sterility of the products.

In the consumer goods sector, thermoforming machines can be used to produce packaging for electronics, cosmetics, toys, and other retail products. Custom-made blister packs and clamshells are some of the most common products produced through thermoforming, offering both protection and visibility for the items inside. These plastic packaging machines enable manufacturers to create eye-catching packaging designs that attract consumers while also providing functional protection for the products.

Hygienic and Durable Packaging Machine Solutions for the Food Industry

In the food industry, hygiene and durability are critical factors in packaging. Food packaging machines, specifically thermoforming machines, ensure that products are protected from contamination while maintaining their freshness. These machines offer high-speed, automated production of custom food packaging, such as trays, cups, and clamshells. The use of materials such as PET or CPET in plastic thermoforming packaging ensures that the packaging is both food-safe and capable of withstanding refrigeration or freezing.

The durability of thermoform packaging is essential for food items that need to be transported over long distances or stored for extended periods. By using thermoforming machines from INPAK, food manufacturers can produce packaging that is sturdy enough to handle the rigors of shipping and handling while maintaining the integrity of the product inside. Moreover, these machines enable manufacturers to create sustainable food packaging options that are recyclable, appealing to environmentally-conscious consumers.

One of the significant advantages of thermoforming machines in the food packaging industry is their ability to produce customized packaging solutions. Whether it’s for portion control, product differentiation, or convenience, thermoform packaging offers flexibility that is unmatched by other packaging methods. INPAK’s food packaging machines are engineered to provide manufacturers with the ability to produce packaging that enhances the consumer’s experience while meeting the highest standards of hygiene and durability.

Thermoforming Machine for Thermoform Packaging Manufacturer

For any manufacturer involved in producing thermoform packaging, investing in high-quality thermoforming machines is crucial. These machines are the backbone of the production process, offering precise molding capabilities that ensure consistent product quality. Whether a company is manufacturing plastic packaging machines for food, medical, or industrial products, thermoforming machines allow for the efficient creation of customized packaging solutions that meet customer needs.

As a thermoforming machine manufacturer, INPAK offers cutting-edge machines that are designed to deliver superior performance and long-lasting results. Their machines are engineered to handle a variety of materials, ensuring that manufacturers can meet the diverse packaging requirements of their clients. With the ability to produce different types of packaging, such as trays, containers, and blister packs, these machines offer the versatility needed to stay competitive in the packaging industry.

Choosing the right thermoforming machine is essential for companies looking to enhance their production capabilities. INPAK’s machines are not only efficient but also cost-effective, reducing energy consumption and labor costs. By investing in thermoforming machine solutions from INPAK, manufacturers can optimize their production processes, increase throughput, and improve product quality—all while contributing to sustainability efforts with recyclable materials.

INPAK: Thermoforming Packaging Machine Solutions

INPAK is a trusted leader in providing thermoforming packaging solutions to businesses across various industries. With a range of innovative thermoforming machines, INPAK offers cutting-edge technology that is designed to enhance production processes, improve efficiency, and meet the highest standards of quality. As a top-tier thermoforming machine manufacturer, INPAK is committed to providing businesses with the tools they need to succeed in the competitive packaging market.

The company’s thermoforming machines are ideal for producing plastic thermoforming packaging solutions that meet the unique needs of their clients. From food packaging machines to medical packaging solutions, INPAK’s machines are designed to produce high-quality, durable, and eco-friendly packaging that not only protects products but also enhances their visual appeal. By offering tailored solutions, INPAK helps manufacturers create packaging that aligns with their specific product requirements.

For businesses looking to invest in thermoforming machine solutions, INPAK provides unparalleled expertise and support. With a focus on innovation and sustainability, INPAK continues to lead the industry in providing plastic packaging machines that deliver reliable and efficient results. By choosing INPAK, manufacturers can take advantage of cutting-edge technology to stay ahead of the competition and meet the growing demand for sustainable packaging solutions.