Advanced Plastic Thermoforming Equipment for Modern Packaging Needs

In today’s rapidly evolving packaging industry, businesses are increasingly turning to plastic thermoforming equipment to meet diverse production needs. Plastic thermoforming machines have revolutionized the way manufacturers create packaging, offering precision, efficiency, and versatility. These advanced machines allow companies to produce high-quality plastic packaging machines for food, medical, and industrial applications, catering to modern standards of hygiene, durability, and design. With innovations in automation and material handling, modern thermoforming machines have become a central component of competitive production lines.

Table of Contents

The demand for plastic thermoforming equipment has surged due to its adaptability in handling multiple materials such as PET, PP, PS, PVC, CPET, OPS, and PLA. This material versatility ensures that businesses can maintain sustainability goals while delivering reliable packaging solutions. Plastic sheet thermoforming processes provide manufacturers with the flexibility to design custom shapes, sizes, and thicknesses according to client specifications. As a result, companies can achieve both aesthetic appeal and functional efficiency in their packaging.

For industries aiming for high-speed production, investing in high-speed thermoforming production solutions is now essential. The integration of vacuum technology and servo-driven transport systems in Thermoforming machines ensures precise molding and minimal waste. Companies can optimize production cycles while reducing operational costs, making plastic thermoforming equipment not only an investment in quality but also in long-term profitability.

What is Plastic Thermoforming and How Does It Work?

Plastic thermoforming machines operate by heating plastic sheets until they become pliable and then shaping them using molds. This process can involve vacuum forming machines or pressure-assisted techniques, depending on the required level of detail and material properties. The versatility of plastic thermoforming equipment allows manufacturers to create containers, trays, lids, and other packaging components with consistent precision. By controlling temperature, pressure, and material distribution, businesses can achieve high-quality results suitable for food packaging machines and other applications.

The thermoforming machine manufacturing process begins with selecting a suitable plastic sheet, which is then clamped and heated evenly. Once the sheet reaches the required temperature, it is formed over a mold using vacuum, air pressure, or mechanical force. After cooling, the formed part is trimmed and packaged. Advanced thermoforming machines include features like automatic thermoforming machines and adjustable heater configurations, ensuring reliable production across multiple batches.

One of the key advantages of plastic thermoforming equipment is its adaptability. Manufacturers can modify molds, materials, and machine settings to produce different products without extensive downtime. This flexibility is essential for companies offering custom thermoforming solutions, allowing them to meet the unique requirements of clients in industries ranging from food packaging to industrial plastic forming machine factories. Modern thermoforming equipment streamlines production, reduces material waste, and enables businesses to scale operations efficiently.

Key Features of High-Quality Thermoforming Machines

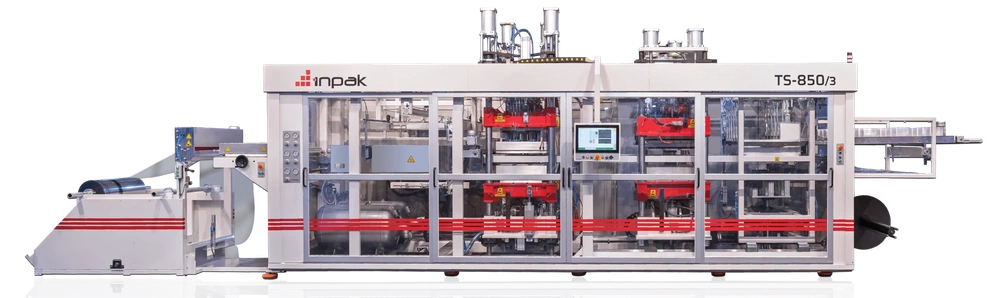

High-quality plastic thermoforming machines are defined by their precision, speed, and durability. These machines often feature ergonomic human-machine interfaces and advanced control software, providing operators with ease of use and real-time monitoring of production processes. Remote access capabilities allow technicians to troubleshoot issues and optimize performance without physical intervention. As a result, businesses benefit from minimal downtime and enhanced productivity.

Another important feature of premium thermoforming equipment is its material compatibility. Machines that support PET, PP, PVC, PS, OPS, CPET, and PLA ensure manufacturers can address a wide range of production needs while maintaining environmentally friendly practices. Plastic sheet thermoforming technologies integrated into these machines allow precise control over material distribution, resulting in uniform, high-quality products suitable for plastic packaging machines and food packaging machines.

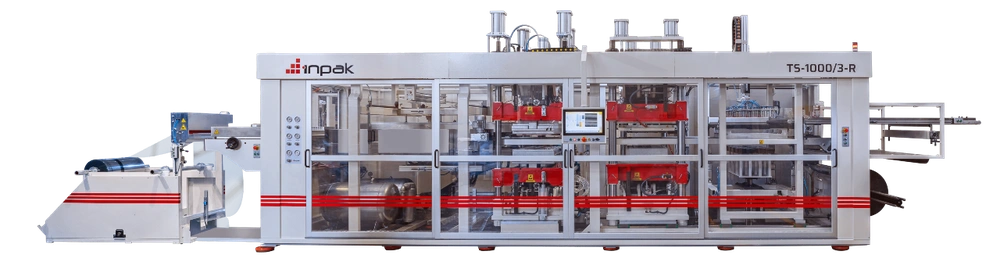

The integration of vacuum and pressure systems in thermoforming machines ensures high accuracy and consistency. Features such as servo-driven transport, 3rd motion servo plugs, and long-life bearing systems contribute to reliable performance under continuous operation. Whether a business requires a heavy-duty thermoforming press or a more compact unit for small-scale production, advanced plastic thermoforming equipment guarantees efficiency, durability, and precise output.

Types of Thermoforming Equipment for Different Packaging Solutions

There is a wide variety of thermoforming equipment tailored to specific packaging requirements. Vacuum forming machines are ideal for lightweight and detailed components, offering cost-effective production for plastic packaging machines. Meanwhile, pressure-assisted or mechanical forming machines are suitable for more rigid or complex products, ensuring uniformity and strength in packaging solutions.

Some manufacturers invest in automatic thermoforming machines for high-volume production. These machines streamline the process from heating to forming and trimming, reducing labor costs and maximizing throughput. For businesses seeking specialized packaging solutions, custom thermoforming solutions provide flexibility in mold design, material selection, and production speed. This versatility allows companies to create unique packaging that enhances brand recognition and consumer appeal.

Industrial-scale thermoforming machine manufacturers also offer high-speed thermoforming production units capable of handling multiple molds simultaneously. These machines are used in sectors such as food, medical, and consumer goods, where speed and precision are critical. From compact thermoforming machines for small enterprises to large-scale industrial thermoforming machinery, the choice of equipment depends on production requirements, material types, and output volume.

Benefits of Using Advanced Thermoforming Technology

Investing in plastic thermoforming equipment offers significant advantages for manufacturers. One major benefit is efficiency. Modern thermoforming machines reduce production time while maintaining consistent quality. Automated systems and precise controls help eliminate errors, minimize waste, and lower operational costs, making thermoforming machine production highly cost-effective.

Another benefit is flexibility. Plastic sheet thermoforming allows manufacturers to adapt to changing market demands and produce diverse packaging designs without extensive equipment changes. Whether producing food packaging machines or specialized industrial containers, thermoforming machines accommodate varying shapes, sizes, and materials. This adaptability ensures businesses can meet client specifications while remaining competitive.

Durability and longevity are additional advantages of high-quality thermoforming equipment. Machines with long-life systems and robust mechanical components withstand continuous operation, reducing the need for frequent maintenance. By choosing advanced plastic thermoforming machines, manufacturers enhance production reliability, ensure product consistency, and optimize return on investment over time.

Industries That Rely on Plastic Thermoforming Machines

Plastic thermoforming machines are integral to numerous industries, particularly those requiring high-quality, customizable packaging. The food industry relies on food packaging machines to create trays, containers, and protective packaging that ensures freshness and hygiene. Plastic thermoforming equipment supports compliance with safety standards while delivering visually appealing packaging designs.

The medical and pharmaceutical sectors also depend on thermoforming machines for producing sterile packaging, trays, and containers. Precision and reliability are crucial in these industries, and advanced thermoforming machine suppliers provide machines capable of maintaining strict quality control. Similarly, industrial manufacturers utilize industrial thermoforming machinery to produce durable parts, protective components, and specialized packaging for logistics and distribution.

Consumer goods companies benefit from plastic thermoforming machines for custom packaging solutions. From electronics to household products, plastic forming machine factories use these machines to create packaging that enhances product protection and presentation. Custom thermoforming solutions allow brands to differentiate themselves in competitive markets while maintaining high production efficiency.

How to Choose the Right Thermoforming Equipment for Your Business

Selecting the ideal plastic thermoforming equipment requires consideration of multiple factors. First, businesses must evaluate production capacity and speed requirements. High-volume operations benefit from high-speed thermoforming production machines, while smaller enterprises may opt for standard thermoforming machines suitable for flexible production runs.

Material compatibility is another critical consideration. Manufacturers should ensure the chosen equipment supports PET, PP, PVC, PS, OPS, and PLA sheets. Plastic sheet thermoforming capability is essential for creating uniform, high-quality products while accommodating client specifications. Additionally, businesses must consider whether they need vacuum forming machines or pressure-assisted thermoforming machines depending on product complexity and design.

Finally, features such as automation, mold flexibility, and maintenance requirements influence the choice of thermoforming machine manufacturers. Investing in automatic thermoforming machines with remote access, sensitive positioning systems, and long-life components ensures long-term efficiency. Partnering with reputable thermoforming machine suppliers guarantees reliable production, technical support, and access to custom thermoforming solutions for evolving market needs.

Future Trends in Thermoforming Machinery and Packaging

The future of plastic thermoforming machines is shaped by automation, sustainability, and innovative material handling. Advanced thermoforming equipment will increasingly incorporate AI-assisted production monitoring, predictive maintenance, and energy-efficient components to reduce operational costs and environmental impact. Plastic packaging machines will become smarter, capable of adjusting parameters in real-time to maintain quality across diverse materials.

Sustainability trends are driving the adoption of eco-friendly materials in thermoforming machine production. Recyclable plastics and biodegradable sheets are being integrated into plastic sheet thermoforming processes, enabling manufacturers to meet regulatory requirements and consumer expectations. Companies investing in custom thermoforming solutions can offer environmentally responsible packaging without sacrificing quality or performance.

Future developments in industrial thermoforming machinery will focus on speed, precision, and versatility. High-speed, heavy-duty thermoforming press units will cater to growing market demands for large-scale production. Enhanced thermoforming mold design and automation capabilities will streamline processes, reduce labor dependency, and increase overall production efficiency. Manufacturers adopting these trends will remain competitive in global markets.

Why Choose INPAK for Premium Thermoforming Solutions?

INPAK stands out among thermoforming machine manufacturers for delivering cutting-edge plastic thermoforming equipment tailored to modern packaging needs. Our machines combine efficiency, precision, and reliability, providing manufacturers with advanced solutions for plastic packaging machines, food packaging machines, and industrial thermoforming machinery. Each unit is engineered to enhance productivity while reducing operational costs.

Our portfolio of plastic thermoforming machines includes high-speed production lines, vacuum forming machines, and automatic thermoforming machines, all designed to accommodate a variety of materials. With expertise in thermoforming machine manufacturing and mold design, INPAK delivers custom thermoforming solutions that cater to unique business requirements. Partnering with INPAK ensures access to durable, innovative, and versatile thermoforming equipment.

Choosing INPAK also means benefiting from comprehensive support, including maintenance, training, and remote troubleshooting. As a leading thermoforming machine supplier, we help businesses optimize their production lines and adopt the latest technological advancements. Our commitment to quality, sustainability, and innovation positions INPAK as the preferred provider for plastic forming machine factories, high-speed production needs, and tailored thermoforming machine for packaging solutions.