Plastic Production Machine Prices

When purchasing a plastic production machine, prices usually vary depending on factors such as quality, capacity, technology, and brand reputation. First, it is very important to determine the production capacity you need for your machines. Machines with higher production capacities are generally more expensive, but for large-scale manufacturers, these machines can be a more sensible investment in terms of efficiency. Additionally, factors like energy efficiency, maintenance requirements, and machine lifespan also influence the pricing.

Table of Contents

When evaluating prices, it is necessary to look at the prices of different types of machines as well. Thermoforming machines differ in price due to their use in different production processes. The types of materials the machines can process and the efficiency level in production processes are also among the factors affecting price. Moreover, machines based on advanced technology generally come with higher price tags due to their newer and more developed features.

Lastly, after-sales support services, warranty periods, and user training should also be considered. Pricing is not limited to the machine itself; additional services necessary for your business to maintain continuous high-quality production also play an important role. Maintaining good communication with suppliers can help you consider these factors to reduce long-term operating costs.

What Is the Plastic Production Process?

The plastic production process consists of a series of stages used to shape and process various plastic materials. First, plastic granules or sheets used as raw materials are melted at the appropriate temperature. Then, this molten material is shaped into the desired form using different production methods. This process is typically carried out with devices such as plastic injection machines and thermoforming machines. Injection molding and thermoforming are the most common methods used in plastic production.

Injection molding is based on injecting the plastic material into molds to obtain the desired shape. This method is particularly popular among manufacturers of plastic packaging machines and plastic food containers. On the other hand, Thermoform machines heat plastic sheets to make them flexible and then shape them into molds using vacuum or pressure. This process is generally used in the production of plastic packaging machines, especially for products like food packaging.

Finally, the plastic production machine process is completed with a quality control stage. The produced plastic products are tested for compliance with certain standards, and if any defects are detected, the product is reprocessed. At this stage, the precision and speed capacity of the machines are of great importance. High-quality and efficient machines minimize error rates during production and offer the possibility of faster and more productive manufacturing.

What Does a Plastic Injection Machine Do?

A plastic injection machine is a device that injects liquid plastic material into a mold under high pressure to shape it into the desired form. These machines have a wide range of applications in plastic production and are frequently preferred in the manufacturing of plastic packaging machines. Plastic injection machines are ideal for large-scale production, as they can produce at high speeds and create products with complex geometries.

These machines are particularly important tools for plastic food container manufacturers and buyers of plastic cup production machines. Especially in the food sector, where sterile and durable packaging products need to be produced quickly, injection machines operate with high precision, saving time and costs. Additionally, various materials such as PET, PP, and PS plastics can be processed with plastic injection machines, making them suitable for different industrial products.

The design of injection machines includes advanced features that increase operational efficiency. Thanks to automation and digital control systems, operators can manage the machine more efficiently. These features minimize errors on the production line and help improve quality in the plastic packaging machines sector. Modern versions of injection machines are equipped with energy-efficient technologies, offering environmentally friendly solutions.

What Is a Plastic Production Machine?

A plastic production machine is an industrial device used to process plastic raw materials and produce various plastic products. These machines involve stages of heating, shaping, and cooling the plastic material. Plastic production machines can generally be of various types such as thermoforming machines or plastic sheet production machines. Each type is designed according to specific production processes and the products to be manufactured.

A plastic production machine is typically designed to provide fast and efficient production. Machines like plastic cup production machines are widely used in the food sector. These machines are capable of high-volume production and can produce high-quality products at low costs. The sizes and production capacities of machines can be customized according to the production needs of businesses.

Finally, maintenance and service are very important for plastic production machines. Regular maintenance is essential for efficient machine operation. Especially devices like thermoforming machines play a critical role in production lines and need to operate flawlessly. Additionally, after-sales support and user training services are crucial, as these services ensure that businesses can use the machine efficiently.

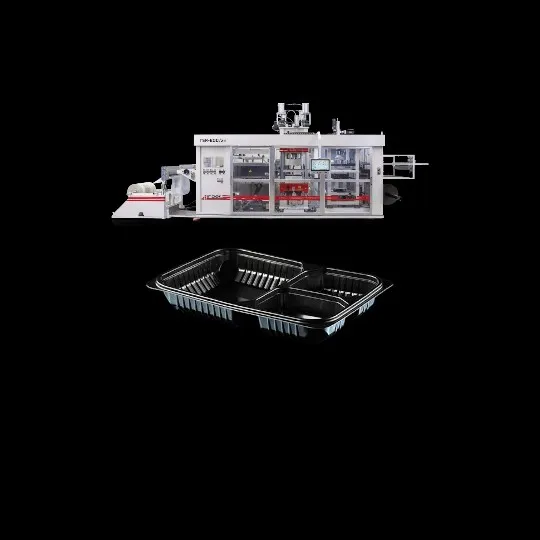

Plastic Thermoforming Machines Prices and Suppliers

Plastic thermoforming machine prices vary according to the technology used and production capacity. These machines, when combined with machines like plastic sheet production machines, enable large-scale production in big manufacturing areas. Thermoforming machines shape products with high precision, increasing product quality. Although prices vary according to capacity and features, these machines are generally a valuable investment for businesses producing high-quality packaging at lower costs.

Suppliers of thermoforming machines usually consist of manufacturers with many years of experience. When choosing a thermoforming machine manufacturer, it is important to consider whether the machine suits its intended use. Machines that cater to different sectors such as food packaging, medical packaging, or industrial packaging may vary in price. Therefore, contacting plastic packaging machine manufacturers to select the device most appropriate for your business needs is crucial.

When purchasing a plastic thermoforming machine, the energy efficiency and long-lasting design of the machines should also be considered. Additionally, maintenance and repair processes directly affect the operational costs of your business. For this reason, establishing long-term partnerships with plastic packaging machine manufacturers is an important step for sustainable production and high return on investment.

Advantages of Plastic Molding Machines for Plastic Food Container Manufacturers

One of the most important requirements for plastic food container manufacturers is to produce durable packaging that stores food products hygienically. Using plastic molding machines makes it possible to produce these packages with high quality and durability. Molding machines, especially combined with high-speed devices like plastic thermoforming machines, facilitate the production of large quantities of food containers with consistent features.

A plastic molding machine offers flexibility to food container manufacturers. By using molds of different sizes and shapes, custom designs can be created. This feature is a significant advantage for customers demanding customized food packaging. Plastic molding machines accelerate production processes, helping businesses save time and costs.

What to Consider When Buying a Plastic Cup Production Machine

When purchasing a plastic cup production machine, one of the most important factors is the speed and efficiency of the machine. These machines typically operate with fast production and high capacity, which is a great advantage especially in the food and beverage industries. In addition to production speed, the quality and durability of the products produced by the plastic cup production machine are also important criteria.

Another aspect to consider is the compatibility of the machine with different material types. Machines compatible with materials such as PET, PP, and PS offer wide production options and accelerate the production process. Additionally, energy-efficient features of the machines help reduce production costs for businesses.

Finally, after-sales support services should be prioritized when purchasing a plastic cup production machine. Maintenance and repair services are critical for maintaining high performance in the long term. As a company, INPAK offers machines that best meet customer demands in the sector, increasing companies’ efficiency.

INPAK Plastic Production Machine Solutions

INPAK is one of the leading manufacturers in the plastic production machine sector. We offer plastic production machine solutions that serve various industries with high quality and efficiency. As INPAK, we manufacture thermoforming machines that provide customizable solutions according to our customers’ production needs. From plastic packaging machine production to specific production solutions like plastic cup production machines, INPAK’s machines are suitable for all types of production processes.

Our plastic production machines incorporate the latest technologies to ensure efficiency and energy savings. Especially as a thermoforming machine manufacturer, we produce some of the fastest and highest quality plastic packaging machines in the industry. INPAK offers great advantages in terms of energy efficiency, increasing energy savings up to 30%, which helps businesses reduce costs over the long term. Our machines are equipped with user-friendly automation systems and industrial PCs, allowing operators to easily manage production processes.

Furthermore, INPAK offers flexible design options and high production capacity with its plastic thermoforming machines. We customize each machine according to the special production requirements of our customers. Serving diverse sectors such as food packaging, medical product packaging, and industrial packaging, we provide the most suitable solutions. We also strengthen our leadership in the industry with after-sales support and training services. At INPAK, customer satisfaction is our priority, and we provide solutions for all production needs, ensuring a high return on investment for businesses.