The Role of Machines in the Plastic Packaging Industry

The plastic packaging industry plays a crucial role in the transportation, protection, and storage of food, medical, agricultural, and industrial products. The sustainability and efficiency of this sector significantly increase depending on the technologies used. Vacuum technology stands out as a method that offers significant advantages to plastic packaging manufacturers. Vacuum forming not only enhances the durability of packaging but also helps preserve the freshness of products for longer periods. Additionally, it allows the plastic material to be shaped more thinly, which reduces material usage and thus helps lower costs.

Table of Contents

Thermoform machines are used in the process of heating plastic sheets, shaping them, and then pulling them into molds using vacuum. This process operates with high speed and precision, ensuring excellent results. In particular, manufacturers of plastic packaging machines use vacuum technology to provide more flexible and customizable solutions to their customers across various sectors. The packaging produced typically minimizes problems such as breakage, deformation, and deterioration, ensuring product safety during transportation.

Another major advantage of vacuum technology is its ability to speed up production processes, allowing companies to manufacture more products. Plastic packaging producers can increase their efficiency in packaging production and work with less waste by using vacuum thermoforming machines. This offers both economic and environmental benefits for companies in the sector. Moreover, the high precision achieved during the shaping of products in plastic packaging production makes the packaging more aesthetic and functional.

The Role of Machines in the Plastic Packaging Industry

Advantages of Vacuum Thermoform Machines for Plastic Packaging Manufacturers

Thermoform machines are among the most efficient production tools in the industry due to the numerous advantages they offer to plastic packaging manufacturers. Firstly, thanks to vacuum technology, plastic packaging machines operate with lower energy consumption while achieving high efficiency. Compared to traditional methods, production can be carried out faster and with energy savings. This reduces production costs and increases the competitiveness of businesses. Especially for large-scale manufacturers, the high-speed operation of vacuum thermoforming machines significantly increases production capacity.

Another advantage is that vacuum technology enables plastic packaging manufacturers to consume less material. This technology pulls each part of the sheet into the desired shape, allowing maximum results with minimal plastic material. This significantly reduces material costs while also supporting environmental sustainability. Thermoform machines make it possible to produce more items using less plastic material, creating an environmentally friendly production process.

Another important advantage of vacuum thermoform machines is their customizable production processes. During the manufacturing of thermoform machines, different molds and designs can be used according to user needs. This makes it possible to create solutions tailored to every sector. Particularly for food packaging machine manufacturers, vacuum thermoforming machines enable the production of hygienic, aesthetic, and durable packaging. These machines assist in producing strong and leak-proof packaging ideal for the transport and storage of food products.

Contributions of Vacuum Technology in Food Packaging Production

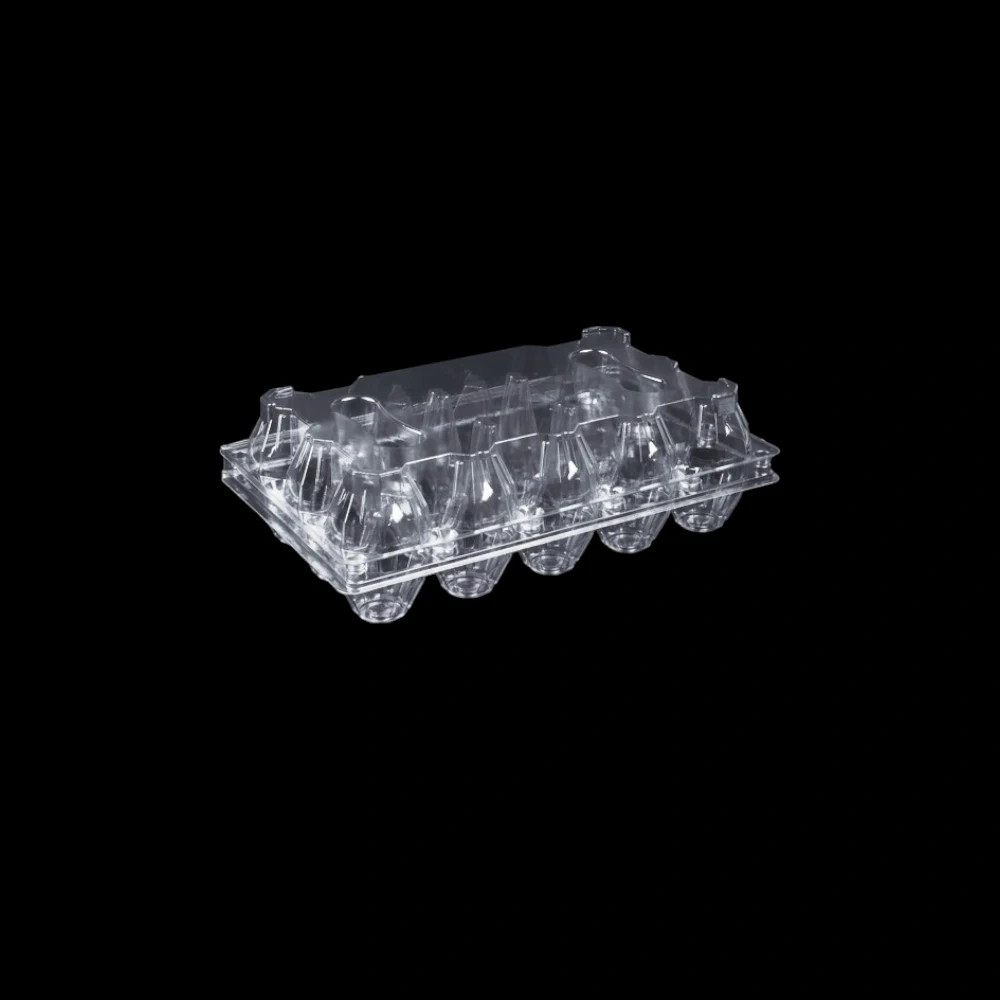

Food packaging plays a vital role in keeping products fresh and preventing spoilage during transportation. Vacuum technology provides a major advantage to food packaging manufacturers in meeting these requirements. Thanks to vacuum thermoforming machines, food packaging gains the durability and sealability necessary for especially fresh products. While protecting products from external factors and preserving their freshness for extended periods, the aesthetic appearance of the packaging is also improved. This is a significant advantage for food packaging machine manufacturers aiming to compete in the market.

Vacuum thermoforming machines not only ensure the physical protection of food packaging but also enhance product appearance. With plastic packaging machines, the transparency and aesthetic presentation of food items can be improved. Moreover, since vacuum technology allows the use of thinner plastic materials, this helps reduce costs and ensures more sustainable production processes. This feature is especially important for companies involved in large-scale food production.

Another key contribution is compliance with hygiene standards. Thermoform machine manufacturers produce food packaging in a sterile and safe manner using vacuum technology. This protects food products from microbiological risks and allows safe delivery to the end consumer. During plastic packaging production, vacuum thermoforming machines can be designed to meet such hygienic requirements and maintain high-quality standards throughout the production process.

The Role of Machines in the Plastic Packaging Industry

The Role of Vacuum Thermoform Machines in Sustainable Packaging

Sustainability has become one of the most important agenda items in today’s plastic packaging industry. Vacuum thermoform machines play a vital role in reducing environmental impact and producing sustainable packaging solutions. Vacuum technology allows more packaging to be produced with less plastic material. This reduces the amount of waste and supports environmental sustainability. Additionally, vacuum thermoforming machines contribute to making production processes more eco-friendly by providing energy efficiency.

Companies that manufacture thermoform machines are taking a significant step toward producing more sustainable packaging by utilizing the advantages of vacuum technology. Especially plastic packaging machine manufacturers are offering environmentally conscious products by using recyclable materials and consuming fewer resources. This provides businesses with long-term economic and environmental benefits. Furthermore, the growing importance of sustainable packaging has a significant impact on product marketing.

Vacuum thermoforming machines also allow for the more efficient use of recyclable materials. These machines enable plastic packaging manufacturers to produce more with less material. This is a major advantage from both economic and environmental perspectives. Thanks to vacuum technology, plastic packaging can be more easily reprocessed and recycled, which minimizes the environmental damage caused by plastic waste.

Thermoform Machines Enhancing Efficiency in the Plastic Packaging Industry

Thermoform machines play a critical role in increasing efficiency for plastic packaging manufacturers. Vacuum thermoform machines significantly boost production speed, allowing businesses to produce more goods. These machines can reach high production speeds, such as 75 cycles per minute, to meet the demands of large-scale manufacturers. Moreover, since their designs require less labor, they also help save on labor costs. This feature helps plastic packaging machine manufacturers increase their competitive edge in the industry.

Another efficiency-enhancing feature of thermoform machines is their ability to support customized production processes. During plastic packaging production, various sizes and shapes of packaging can be manufactured using vacuum machines. This flexibility is a major advantage for companies aiming to offer solutions tailored to customer needs. Additionally, making production processes faster and more flexible allows businesses to produce more at lower costs.

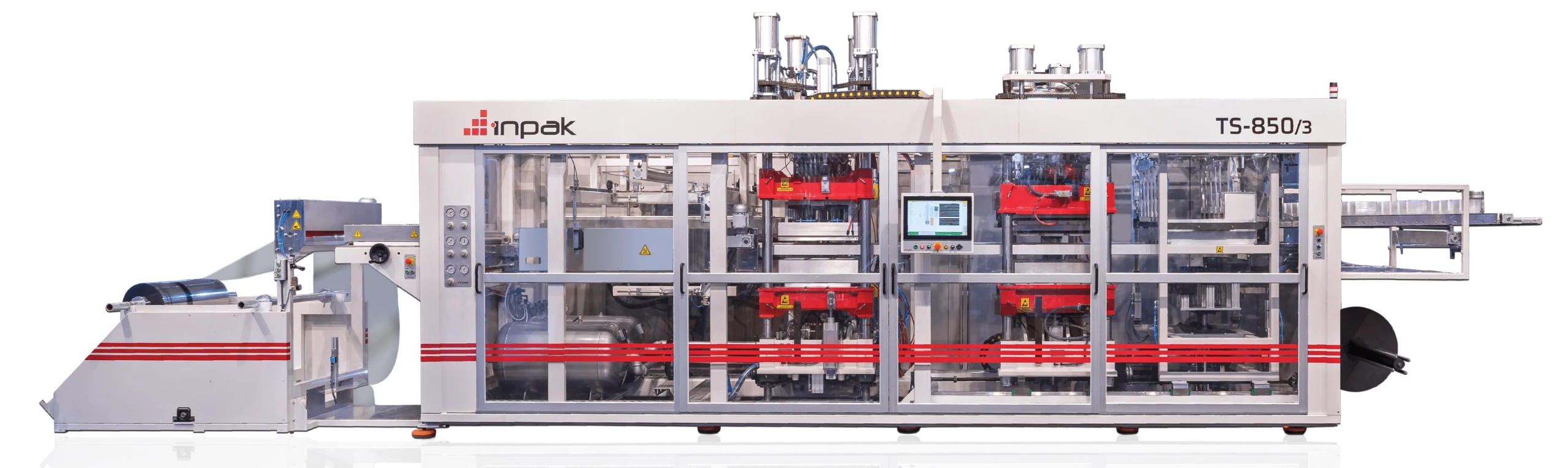

INPAK’s thermoform machines offer the most efficient and technologically advanced solutions in the industry. These machines enhance production process efficiency by ensuring energy savings and provide long-term return on investment. As a thermoform machine manufacturer, we at INPAK offer high-speed production, low cost, and eco-friendly solutions to companies in the industry.

The Role of Machines in the Plastic Packaging Industry

INPAK Thermoform Machine Solutions

As a leading thermoform machine manufacturer for the plastic packaging industry, we offer the latest technologies in the field and provide customized solutions to meet all kinds of packaging needs. At INPAK, we deliver high efficiency, durability, and flexibility, giving plastic packaging manufacturers a strong competitive advantage. Businesses operating in the food, medical, industrial, and agricultural sectors can optimize their production processes, increase production speed, and reduce costs using our machines.

INPAK thermoform machines are fully customizable according to customer requirements and can operate with molds of various sizes. This offers greater flexibility and versatility for plastic packaging manufacturers. Vacuum thermoform machines enable the precise shaping of plastic sheets and ensure that each product is manufactured at high quality and under hygienic conditions. Thanks to the advanced technology used in the manufacturing of our thermoform machines, INPAK offer ideal solutions for businesses that conduct large-scale production.

At INPAK, we promote energy efficiency while minimizing environmental impact. Our machines provide up to 30% energy savings compared to traditional methods and reduce waste levels during production processes. The advantages offered by our plastic packaging machines help businesses meet their sustainability goals and achieve high returns on investment in the long term. With the automation systems and user-friendly interfaces we provide, operators can work more efficiently and manage production processes more easily.