Large Vacuum Forming Machines for Industrial Applications by INPAK

INPAK leads the way in industrial thermoforming machine production, offering advanced large vacuum forming machines that are engineered for high-volume, heavy-duty applications. Whether you’re in automotive, logistics, medical, or consumer packaging sectors, INPAK’s vacuum forming machine large systems provide scalable solutions that combine speed, precision, and durability. Our thermoforming machine manufacturing expertise ensures that even the most complex shapes and materials are processed with consistency and efficiency.

Table of Contents

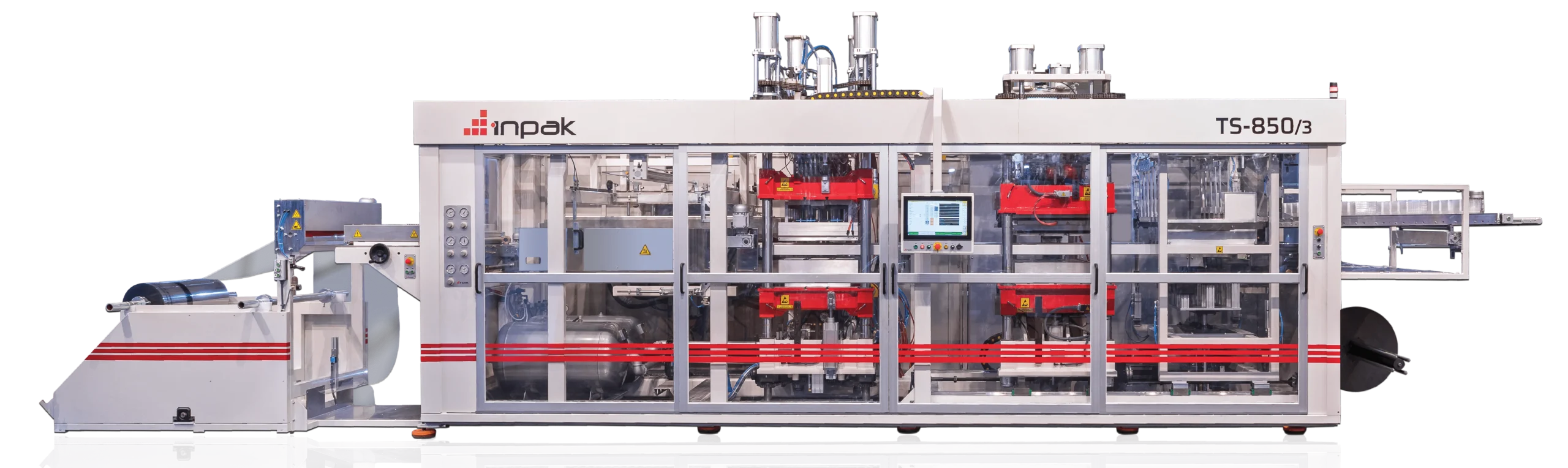

Our plastic vacuum forming machine line is specifically developed for producing robust components that require deeper draw, thicker gauge materials, and superior strength. These thermoforming packaging machine manufacturing solutions allow manufacturers to produce high-quality industrial trays, housings, panels, and containers in large volumes. Thermoforming machine are designed with reinforced frames, servo-driven movements, and automated heating control systems to maximize accuracy and uptime.

With over two decades of experience as a thermoforming machine manufacturer, INPAK delivers cutting-edge solutions for businesses looking to upgrade their production capabilities. Our thermoforming machine suppliers network spans multiple industries, ensuring access to tailored technologies for demanding production lines. From plastic forming machine innovations to automatic thermoforming machine production, we are your trusted partner in modernizing industrial packaging and shaping the future of plastic packaging machine systems.

Large Vacuum Forming Machines for Industrial Applications by INPAK

What is a Vacuum Forming Machine?

A vacuum forming machine is a type of plastic forming machine that shapes plastic sheets into specific configurations by applying heat and vacuum pressure. As the plastic softens, it is stretched over a mold and suctioned tightly to form intricate, durable shapes. This process is essential in the production of packaging components, industrial trays, panels, and more.

Large-scale vacuum forming machines are especially valuable for their ability to handle substantial plastic sheets and create larger parts with precision. These plastic vacuum forming machines are used in various sectors, including automotive, construction, and heavy-duty packaging. They are designed to meet the rigorous demands of industrial-scale production, offering efficiency and accuracy.

At INPAK, we specialize in the development of vacuum forming machine large systems, tailored for industries requiring robust, oversized components. As a leading thermoforming machine manufacturer, INPAK ensures each vacuum former machine is built to deliver reliability, speed, and operational consistency.

What is the Vacuum Forming Process for Plastic Manufacturing?

The vacuum forming process begins by clamping a plastic sheet into the machine, where it is heated until pliable. Once softened, the sheet is formed over a mold, and vacuum pressure pulls the material tightly against the mold’s contours. The result is a precise, uniform shape with minimal waste and excellent repeatability, making the vacuum forming machine a cornerstone of plastic forming machine operations.

This technique is commonly applied in plastic packaging machine manufacturing, where both design flexibility and hygiene are critical. The thermoforming packaging machine manufacturing sector leverages vacuum forming for items like food trays, blister packs, and clamshell containers. Due to its low tooling cost and fast cycle times, vacuum forming is also ideal for prototyping and small to medium production runs.

INPAK’s advanced automatic thermoforming machine production solutions incorporate state-of-the-art vacuum forming features. These systems support multiple materials and deliver high-speed cycles for optimal output in both food packaging machine and heavy industry applications.

Large Vacuum Forming Machines for Industrial Applications by INPAK

What are the Differences Between Vacuum Forming, Thermoforming, and Pressure Forming?

Thermoforming machines heat plastic sheets to a pliable state and then form them over a mold using different methods. Vacuum forming machines utilize suction to shape the heated plastic, making them ideal for shallow or simple geometries. Pressure forming, in contrast, adds air pressure to the back side of the plastic, producing more detailed and sharper results compared to vacuum forming.

While all three processes fall under the thermoforming machine umbrella, they serve different product needs. Vacuum forming machine large systems are preferred in industrial applications where lightweight and structural plastic parts are needed. Pressure forming is selected when cosmetic detail or tight tolerances are required, often seen in consumer electronics or high-end packaging.

INPAK is among the leading thermoforming machine suppliers and thermoforming machine manufacturing companies, offering custom systems for each forming method. Whether you require industrial thermoforming machine production or scalable thermoforming machine supply, INPAK delivers solutions tailored to your product goals.

How Does Vacuum Forming Machine Work?

A vacuum forming machine works through a sequence of controlled mechanical and thermal steps. The plastic sheet is first loaded and clamped into the frame, then heated using ceramic or halogen heaters until it becomes flexible. Once softened, the sheet is quickly lowered over a mold, and vacuum pressure is applied to suck the plastic tightly against it. The material cools in place and is then trimmed and ejected, completing the cycle.

Large vacuum forming machines come equipped with programmable logic controls and servo-driven components to ensure accuracy in part dimensions. These machines are essential in sectors requiring high-volume, high-durability products like transport trays, engine bay liners, and construction panels. The precision and repeatability of these systems make them a vital component of thermoforming machine production strategies.

As a trusted thermoforming machine producer, INPAK integrates intuitive controls and efficient energy systems into all its plastic vacuum forming machine models. Our machines stand out in the market for their innovation, longevity, and compatibility with various thermoplastics.

Large Vacuum Forming Machines for Industrial Applications by INPAK

Materials for Vacuum Forming

A wide range of plastic materials can be used in vacuum forming machines, including PET, CPET, PP, PS, PVC, and PLA. These materials offer different properties such as rigidity, transparency, impact resistance, and food safety compliance. Thermoforming machines are specifically designed to accommodate the thermal behaviors of these plastics, ensuring consistent quality during the forming process.

Large vacuum forming machines must be compatible with thicker gauges and more demanding materials, especially for industrial and structural applications. Whether manufacturing appliance panels or automotive interiors, these machines are calibrated to maintain material integrity during forming and cooling. This versatility allows companies to address diverse market needs with a single system.

INPAK, a leader in thermoforming machine manufacturing, ensures that all its systems are engineered for material adaptability. As a top thermoforming machine supplier, we provide expert guidance on material selection and machine configuration for every thermoforming machine manufacturing project.

Industrial-Scale Thermoforming Machine Production for Heavy Parts

In industrial applications, size and durability matter. Large vacuum forming machines from INPAK are built to produce oversized parts with complex shapes and high strength requirements. These thermoforming machines are vital in the creation of parts for logistics, construction, and agricultural industries.

Our industrial thermoforming machine production capabilities allow us to build heavy-duty machines with reinforced frames, automated feeding systems, and precision control units. This results in consistent product dimensions and minimal downtime, even in 24/7 production environments. The machines support large mold sizes and deep draw capabilities essential for industrial packaging.

As a recognized thermoforming machine manufacturer, INPAK works closely with manufacturers worldwide to deliver custom thermoforming machine production systems. With our advanced design and engineering support, businesses can scale operations without compromising on quality or reliability.

Rigorous Performance Testing for Large Thermoforming Machines

All large vacuum forming machines developed by INPAK undergo extensive testing to guarantee optimal performance. This includes stress testing, material flow analysis, thermal response calibration, and vacuum pressure accuracy. Ensuring that every vacuum former machine operates flawlessly under industrial conditions is our top priority.

Our testing protocol covers all critical aspects of thermoforming machine manufacturing, including electrical stability, forming cycle precision, and structural robustness. By replicating real-world production conditions, we eliminate variables that could impact performance after installation. This commitment to quality makes INPAK one of the most trusted thermoforming machine manufacturing companies in the industry.

Through our global thermoforming machine supply network, INPAK ensures timely delivery and continued technical support. Our team assists with commissioning, training, and after-sales maintenance, making our thermoforming machines a long-term asset for any manufacturing setup.

Large Vacuum Forming Machines for Industrial Applications by INPAK

INPAK: Powering Industrial Vacuum Forming Innovations

INPAK is redefining innovation in the plastic forming machine sector with its line of large vacuum forming machines and thermoforming machines. We focus on scalable designs that meet the growing needs of both emerging and established industries. Our systems are compatible with automation solutions, helping businesses reduce labor dependency while increasing productivity.

As a top-tier thermoforming machine producer and thermoforming machine supplier, INPAK stands out for its engineering excellence, responsive support, and long-term partnership approach. We have built a reputation for delivering solutions that are not only efficient but also future-ready. Whether you need a thermoforming machine for food packaging or robust systems for structural parts, INPAK has you covered.

Let INPAK be your partner in automatic thermoforming machine production and large-scale plastic forming. Our experience in thermoforming machine manufacturing empowers your business to meet the market’s toughest demands while maintaining cost-efficiency and quality.