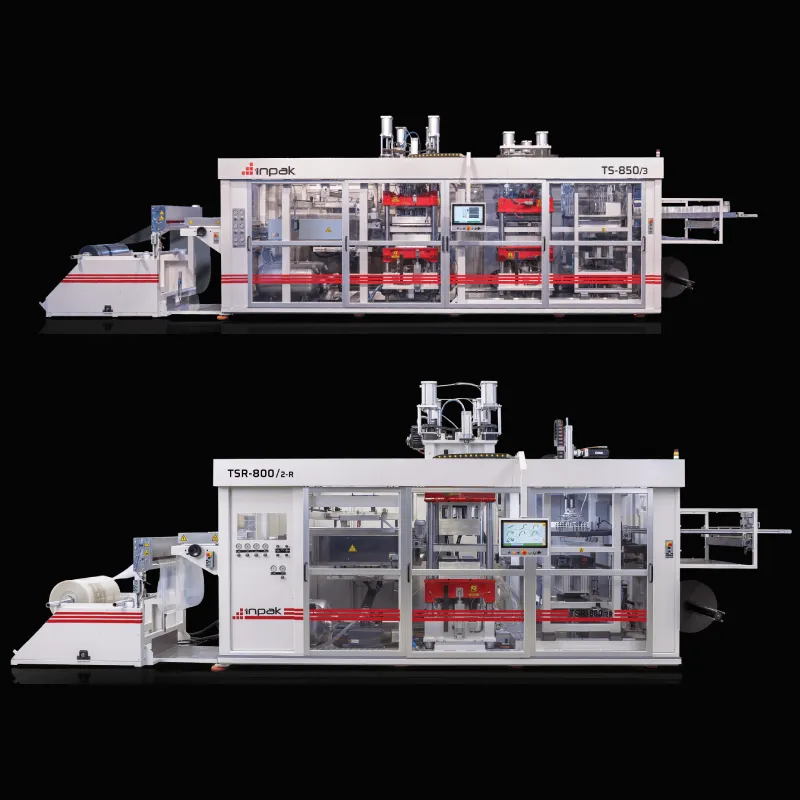

Industrial Plastic Food Packaging Solutions Powered by Advanced INPAK Thermoforming Machines

Industrial food packaging has evolved tremendously over the past decade, with manufacturers seeking efficient, reliable, and versatile solutions to meet global demands. Industrial plastic food packaging solutions are increasingly critical for maintaining product quality, hygiene, and sustainability standards. Advanced thermoforming technologies now allow producers to create high-precision trays, containers, and clamshells that cater to both mass production and customized packaging needs. Businesses around the world rely on these innovations to maintain competitive advantages, improve operational efficiency, and comply with regulatory requirements.

Table of Contents

The integration of automated processes in industrial plastic food packaging solutions ensures consistency and speed across production lines. Thermoforming technology minimizes human error and optimizes material usage, which not only reduces production costs but also supports environmentally friendly initiatives. With modern Thermoforming machines, food manufacturers can achieve high-volume production while maintaining stringent quality controls, ensuring that products remain safe and visually appealing for end consumers.

INPAK’s focus on innovation has positioned it among the leading Thermoforming machine manufacturers globally. By providing cutting-edge equipment for industrial plastic food packaging solutions, INPAK empowers businesses to scale efficiently without sacrificing precision. Their machines are designed to handle a variety of materials, including PET, PP, CPET, and eco-friendly alternatives, making them adaptable to both traditional and sustainable packaging requirements.

High-Efficiency Thermoforming Machines for Industrial Food Packaging

Efficiency is paramount in today’s competitive food packaging industry. High-efficiency Thermoforming machines streamline the production process by combining speed, accuracy, and minimal downtime. Advanced servo-driven mechanisms and precision-controlled heating systems ensure consistent product quality, reducing waste and lowering operational costs. These systems allow manufacturers to respond swiftly to market fluctuations and meet large-scale demands without compromising on quality.

In addition to operational speed, industrial plastic food packaging solutions benefit from machines designed for ease of maintenance and minimal energy consumption. INPAK machines integrate features like automatic lubrication, remote monitoring, and adaptive heating controls that reduce human intervention and improve workflow efficiency. As a result, food producers can focus on production strategy and quality assurance while relying on plastic packaging machines for reliable output.

The demand for industrial thermoforming equipment is increasing as brands strive to deliver durable, hygienic, and visually appealing packaging. High-efficiency Thermoforming machine production ensures that every tray, clamshell, or container meets strict safety standards. By leveraging cutting-edge technology, manufacturers can achieve precise molding, optimal material distribution, and faster turnaround times, positioning themselves as leaders in the food packaging machines sector.

Customizable Plastic Packaging Solutions for Global Markets

Global food markets demand flexibility and innovation in packaging design. Customizable plastic packaging solutions allow businesses to differentiate their products while maintaining functional integrity. Thermoforming technology provides the adaptability needed to create bespoke packaging designs, from specialized trays for frozen meals to innovative clamshell containers for fresh produce. These solutions align with consumer preferences for convenience, durability, and aesthetic appeal.

By working with experienced Thermoforming machine manufacturers, companies can implement Thermoforming machines that support diverse product specifications. Machines capable of processing multiple materials, adjusting mold configurations, and producing complex shapes enable rapid prototyping and shorter production cycles. Consequently, manufacturers can expand their product portfolios and respond quickly to emerging trends in the global market.

INPAK’s portfolio of plastic food packaging machines empowers businesses to explore new markets while maintaining compliance with food safety regulations. Advanced automation and customizable settings in automatic thermoforming systems facilitate high-speed production without sacrificing quality. By embracing these tailored solutions, food producers enhance their ability to meet international standards, gain consumer trust, and increase brand recognition worldwide.

Automated Thermoforming Technology for Faster Production & Lower Costs

Automation in Thermoforming machine manufacturing has revolutionized the food packaging industry by providing faster production and reduced operational costs. Automated systems minimize manual labor, decrease error rates, and optimize material usage. These benefits contribute to overall profitability while allowing manufacturers to maintain consistent production schedules, even during peak demand periods.

Industrial thermoforming equipment with advanced automation also ensures uniformity across all packaging products. Automated Thermoforming machine suppliers design machines capable of high-speed operation while maintaining precise tolerances for tray depth, wall thickness, and sealing surfaces. This level of precision is essential for businesses producing sensitive food items that require airtight and hygienic packaging solutions.

Reducing costs without compromising quality is a key advantage of industrial plastic food packaging solutions powered by automated thermoforming technology. Energy-efficient systems, precise heating controls, and high-speed production cycles allow companies to scale efficiently. INPAK’s expertise in Thermoforming machine manufacturing ensures that each machine delivers reliable performance, enabling food producers to maximize output and profitability in a competitive market.

Eco-Friendly & FDA-Compliant Food Packaging Innovations

Sustainability and regulatory compliance are critical considerations for modern food packaging. Eco-friendly industrial plastic food packaging solutions address both consumer demand for green alternatives and stringent governmental regulations. Thermoforming machines designed to work with recyclable and biodegradable materials enable manufacturers to produce environmentally responsible packaging without sacrificing quality or durability.

Compliance with FDA and other international food safety standards is essential for packaging manufacturers. Plastic food packaging machines must maintain hygienic processes, avoid contamination risks, and deliver consistent product integrity. Advanced automatic thermoforming systems achieve these goals by integrating precise temperature control, vacuum forming technology, and automated quality monitoring throughout the production cycle.

INPAK leads the industry by offering high-speed thermoforming technology that aligns with eco-friendly practices and regulatory requirements. Their machines support versatile material choices, efficient energy consumption, and minimal waste, making them ideal for producing FDA-compliant industrial plastic food packaging solutions. By combining innovation, speed, and sustainability, INPAK enables manufacturers to meet both consumer expectations and legal obligations.

Durable & Hygienic Plastic Trays, Containers, and Clamshells

Durability and hygiene are non-negotiable for food packaging products. Industrial plastic food packaging solutions like trays, containers, and clamshells must withstand transport, storage, and handling without compromising product safety. Thermoforming machines create strong, uniform packaging that protects food items from damage, contamination, and spoilage, ensuring consumer satisfaction.

The precision offered by modern Thermoforming machines guarantees consistent wall thickness, material distribution, and structural integrity. These machines produce packaging capable of maintaining its form under high pressure and temperature variations, making them ideal for diverse applications such as ready meals, fresh produce, and frozen goods. High-quality plastic packaging machines are indispensable for maintaining these standards.

By leveraging industrial thermoforming equipment, food manufacturers can produce packaging that is both functional and aesthetically appealing. From transparent clamshells that showcase fresh products to sturdy trays designed for microwave use, advanced Thermoforming machine suppliers provide solutions that meet both business and consumer expectations. Durability, hygiene, and visual appeal are seamlessly integrated into modern packaging lines, thanks to high-speed and automated Thermoforming machine production.

Country-Specific Thermoforming Trends & Packaging Demands

Packaging demands vary significantly across global markets, influenced by consumer behavior, regulatory standards, and supply chain requirements. Industrial plastic food packaging solutions must be adaptable to these regional differences, offering flexibility in size, material, and design. Thermoforming technology provides the tools necessary to cater to localized preferences and emerging market trends effectively.

Countries with high demand for ready-to-eat meals, fresh produce, or frozen foods require Thermoforming machines capable of high-volume production while maintaining strict safety standards. Plastic food packaging machines that integrate advanced automation and vacuum forming technologies allow manufacturers to meet these diverse requirements efficiently, supporting growth in both domestic and international markets.

INPAK’s experience as a Thermoforming machine manufacturer ensures that its industrial thermoforming equipment can be customized for country-specific needs. High-speed, automated, and precise automatic thermoforming systems allow businesses to respond quickly to regional trends, meet local compliance standards, and deliver consistent quality packaging to end consumers worldwide.

Why Choose INPAK for Premium Thermoforming Machinery?

Choosing the right equipment is crucial for businesses seeking to excel in the competitive packaging sector. INPAK stands out as a leading Thermoforming machine supplier due to its focus on innovation, efficiency, and customer-oriented solutions. By offering a comprehensive range of industrial plastic food packaging solutions, INPAK enables manufacturers to achieve high-quality output, reduce operational costs, and expand production capabilities.

The company’s machines are built for reliability and versatility, capable of producing diverse packaging forms from trays to clamshells using various materials. Plastic food packaging machines from INPAK integrate advanced software, remote monitoring, and automated systems, ensuring precise production and minimal downtime. This level of technological sophistication makes INPAK a preferred choice among global food packaging businesses.

INPAK also emphasizes sustainability and regulatory compliance in Thermoforming machine production. Their machines support eco-friendly materials, energy efficiency, and FDA-approved processes, aligning with modern industry requirements. By choosing INPAK as a Thermoforming machine manufacturer, companies gain access to high-performance, reliable, and future-proof industrial thermoforming equipment that drives growth, efficiency, and innovation in the global packaging market.