Fully Automatic Thermoform Machines: The Production Technology of the Future

In today’s rapidly advancing world of technology, fully automatic thermoform machines stand out as an innovative solution in plastic packaging production. These machines enhance efficiency by fully automating production processes and minimize human errors. Automated systems significantly reduce the need for operator intervention, delivering faster and more reliable production. Additionally, thanks to integrated software and robotic technologies, these machines can be tailored to meet a variety of production needs. While increasing production speed, they also adopt an environmentally friendly approach by reducing energy consumption and material waste.

Table of Contents

Fully automatic thermoform machines automate the process of heating plastic sheets, placing them into molds, and shaping them. This allows manufacturers to produce even complex designs quickly and with high precision. Communication between machines and data tracking makes it easier to monitor and optimize the production process. This technology offers significant advantages for companies engaged in industrial-scale production. Shorter production times and lower error rates help businesses gain a competitive edge in the market.

In conclusion, thermoform machines not only accelerate production processes but also offer cost savings to businesses. Automation reduces maintenance needs and extends the lifespan of the machines, lowering operational expenses. Additionally, less labor is required, allowing businesses to cut down on personnel costs. This technology is expected to advance further in the future, leading to fully digitalized production processes.

Wide Application of Fully Automatic Thermoform Machines

Fully automatic thermoform machines are widely used across various sectors and offer a broad range of applications. One of the most common industries they serve is food packaging. Plastic packaging ensures the hygienic storage and transportation of food products. These machines are especially preferred by food packaging machine manufacturers. Products such as yogurt cups, ready-meal trays, and fruit and vegetable containers can be produced quickly and with high precision using fully automatic thermoform machines. These machines comply with hygiene standards during production, enhancing food safety and extending shelf life.

The medical sector is another major application area for fully automatic thermoform machines. When producing special packaging for medical products requiring sterilization, high precision and hygiene standards are essential. Packaging for items like syringes, surgical tools, and medical devices is produced by thermoform machine manufacturers. These machines ensure the safe packaging of medical products, creating secure usage conditions for both patients and healthcare professionals.

Beyond that, plastic packaging machines are also commonly used in agriculture, automotive, and electronics industries. In agriculture, they are used to produce seedling trays and plant protection packaging, while in the automotive and electronics sectors, they are used for protective packaging of delicate parts. These machines provide safety and durability during transport and storage. Additionally, they offer customized packaging solutions tailored to the specific needs of each sector.

Advantages of Fully Automatic Thermoform Packaging Machines

Fully automatic thermoform packaging machines offer significant advantages in production processes. First, these machines operate with high efficiency, increasing overall production capacity. For companies engaged in large-scale production, automatic systems reduce labor costs and significantly boost production speed. This allows firms to produce more units while simultaneously lowering operational costs. Increased production speed is especially beneficial during high-demand seasons, enabling faster delivery capabilities.

Another key advantage is energy efficiency. Fully automatic thermoform machines are optimized to minimize energy consumption. Compared to traditional thermoform machines, energy savings of up to 30% can be achieved. This not only supports environmentally friendly production processes but also offers long-term economic benefits to businesses. Furthermore, these machines generate less waste and reduce material wastage. This is a critical advantage for companies striving to meet environmental sustainability goals.

Lastly, fully automatic thermoform machines ensure quality control by producing with high precision. Automated control systems are engaged at every stage of the production process, ensuring consistent product quality. This is particularly crucial in the food and medical sectors, where packaging must comply with strict quality standards. These machines perform cutting and forming operations with extreme precision, delivering excellent results to customers.

Energy Efficiency and Eco-Friendly Production with Thermoform Machines

Thermoform machines are essential tools for achieving environmentally friendly production processes. Equipped with the latest technologies, modern thermoform machines consume less energy and generate less waste compared to older models. These machines are particularly optimized for energy savings through advanced heating systems, providing lower energy usage than conventional thermoform machines. In doing so, businesses reduce their energy costs while contributing to environmental protection.

Reduced energy consumption and material waste support sustainable production practices. Plastic packaging machine manufacturers prefer using recyclable materials in their machines to meet the growing demand for eco-friendly technologies. This helps establish a more sustainable production process. At the same time, production is optimized through automated control systems to reduce waste. This not only lowers business costs but also aids in conserving natural resources.

In conclusion, thermoform machines contribute significantly to eco-friendly production processes. Thermoform machine manufacturers utilize next-generation technologies for energy efficiency and waste management, offering both economic and environmental benefits. The use of these machines is a vital step toward a cleaner and more sustainable production future.

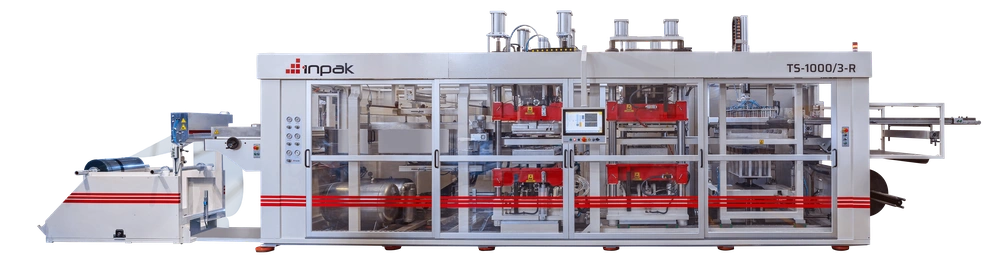

INPAK Thermoform Machines: Efficiency and Flexibility in Industrial Production

INPAK thermoform machines offer high efficiency and flexibility in industrial production. As a thermoform machine manufacturer, we serve numerous industries around the world. Thanks to innovative technologies and automation systems, INPAK thermoform machines provide businesses with major advantages. Equipped with advanced technologies, these machines accelerate the production process while simultaneously improving quality.

INPAK thermoform machines offer customizable solutions for industrial production and can be tailored to the needs of different sectors. These machines are used in industries such as food, medical, automotive, and electronics, each with unique requirements. At the same time, they enable the production of high-quality products with less labor and energy. This ensures a high return on investment over the long term.

We continue to develop solutions that make production faster, more efficient, and more sustainable. Our machines meet the expectations of modern industry with their durability, energy efficiency, and flexible usage capabilities. With INPAK, businesses can confidently take a step into the future of industrial packaging.