Innovative Food Packaging Solutions with Thermoforming Technology

Innovative Food Packaging Solutions with Thermoforming Technology are transforming the way businesses approach food packaging. By integrating advanced thermoforming machines for food packaging, manufacturers can create durable, precise, and aesthetically appealing containers for a wide range of food products. This thermoforming technology in food industry allows for higher production efficiency while maintaining hygiene and safety standards. Whether producing plastic thermoforming packaging for retail, industrial, or consumer applications, food packaging machines equipped with modern features provide significant advantages over traditional methods.

Table of Contents

The evolution of thermoforming machine production has made it possible for companies to adopt automated processes that reduce labor costs, minimize material waste, and improve overall productivity. Thermoforming machines are now essential components of modern food packaging machines, enabling businesses to produce high-quality, uniform packaging at scale. From custom food packaging solutions to vacuum-formed containers, these machines ensure reliability, safety, and consistency across all types of food packaging.

Furthermore, thermoforming machine manufacturers focus on versatility, allowing businesses to adapt to changing market needs. With the ability to handle multiple materials such as PET, PP, PLA, and more, Thermoforming machines enable the production of eco-friendly thermoformed packaging while maintaining structural integrity and visual appeal. This combination of efficiency, sustainability, and customization makes thermoforming technology in food industry a cornerstone of modern food packaging machines.

What is Thermoforming Technology in Food Packaging?

Thermoforming technology in food industry has emerged as a transformative approach for creating durable, versatile, and visually appealing packaging solutions. This process involves heating a sheet of plastic until it becomes pliable and then molding it into specific shapes using a specialized thermoforming machine for food packaging. The resulting plastic packaging machines produce containers that are lightweight yet sturdy, ensuring the safety and quality of the packaged food products. By leveraging precise molding techniques, companies can achieve uniformity and high production efficiency, making food packaging machines essential in modern manufacturing lines.

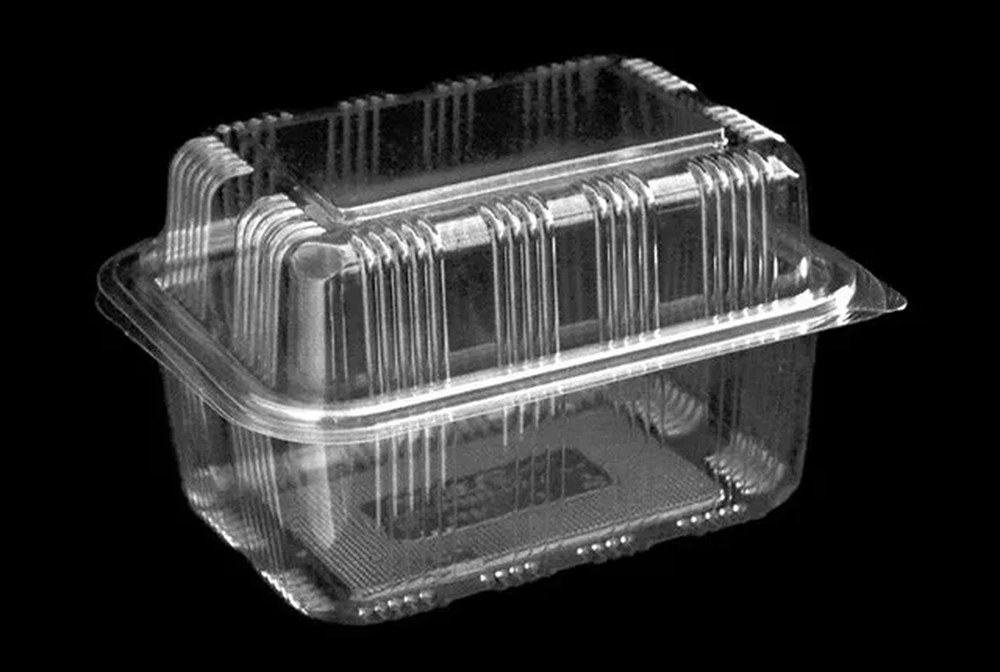

One of the primary advantages of thermoforming technology in food industry is its flexibility in design. Manufacturers can produce a wide variety of containers, trays, and lids suitable for diverse food items, ranging from ready-to-eat meals to delicate pastries. Thermoforming machines allow for intricate designs and custom configurations without compromising production speed. This adaptability makes thermoforming machine production a preferred choice for companies aiming to differentiate their food packaging on store shelves.

Furthermore, thermoforming technology in food industry supports the integration of plastic thermoforming packaging with other packaging innovations, such as vacuum sealing and multi-compartment designs. This ensures that perishable items retain freshness while providing convenience to consumers. By employing food-grade thermoforming plastic, manufacturers can comply with stringent safety and hygiene standards, reinforcing the trustworthiness of their food packaging machines.

Key Benefits of Thermoformed Food Packaging

Thermoformed food packaging offers numerous benefits for both manufacturers and consumers. One of the most notable advantages is its ability to produce high-quality, consistent packaging at scale. Unlike traditional packaging methods, thermoforming machines provide precise control over dimensions and thickness, resulting in uniform containers. This not only enhances product presentation but also reduces material waste, contributing to cost efficiency. Companies investing in thermoforming machine manufacturers can achieve long-term operational savings while maintaining superior product standards.

Another key benefit of thermoformed food packaging is its versatility across different food types. Whether packaging bakery items, frozen foods, or fresh produce, thermoforming machines can accommodate various shapes, sizes, and materials. Plastic packaging machines used in these processes enable rapid adaptation to new product lines without extensive retooling. This flexibility makes custom food packaging solutions highly feasible, allowing brands to create distinctive packaging that aligns with their identity and marketing strategies.

Sustainability is also a major consideration in modern thermoforming machine manufacturing. Many manufacturers now focus on using recyclable or biodegradable food-grade thermoforming plastic to minimize environmental impact. By integrating eco-friendly practices, thermoforming machines not only reduce waste but also support corporate social responsibility initiatives. This positions companies as leaders in providing eco-friendly thermoformed packaging while meeting increasing consumer demand for sustainable food packaging.

Types of Thermoforming Machines for Food Packaging

The food industry relies on a range of thermoforming machines to meet diverse packaging demands. Standard models include single-station machines, rotary machines, and multi-station systems, each offering distinct advantages in production speed and complexity. Thermoforming machine for food packaging varies from compact units suitable for small-scale operations to industrial-grade plastic packaging machines designed for high-volume production. By selecting the right machine, businesses can optimize throughput without compromising quality or durability.

Advanced thermoforming machine production often incorporates automation and intelligent control systems. Features like servo-driven transport, sensitive positioning, and vacuum forming enhance precision, allowing manufacturers to create vacuum forming food containers with consistent thickness and shape. These innovations ensure that food packaging machines operate efficiently while reducing labor costs, making them an attractive investment for companies seeking both scalability and reliability in their thermoforming machines.

Customizable options also exist within thermoforming machine manufacturing, enabling companies to address unique packaging challenges. Machines may support various plastic thermoforming packaging materials, including PET, PP, PS, and PLA. By choosing the appropriate configuration, manufacturers can achieve specific barrier properties, rigidity, and aesthetic finishes in their thermoform packaging manufacturers outputs. This versatility makes thermoforming machines essential tools in producing both standard and innovative food packaging solutions.

Sustainable Thermoforming Solutions for Eco-Friendly Packaging

Sustainability has become a critical driver in the evolution of food packaging machines. Eco-friendly thermoformed packaging relies on recyclable, biodegradable, or compostable food-grade thermoforming plastic to reduce environmental impact. Companies using thermoforming machines can implement circular economy principles by designing packaging that minimizes waste and encourages recycling, making sustainability a core component of their production strategy.

In addition to materials, thermoforming machine manufacturers are focusing on energy-efficient designs. Modern thermoforming machine production integrates advanced heating systems and optimized mechanical components to reduce electricity consumption while maintaining production speed. These energy-efficient plastic packaging machines not only cut operational costs but also support environmentally responsible manufacturing practices, reflecting the growing importance of green initiatives in food packaging.

Consumer perception is another key factor driving sustainable thermoforming solutions. Brands that offer custom food packaging solutions with a reduced environmental footprint gain competitive advantage. By highlighting the use of eco-friendly thermoformed packaging, companies can attract environmentally conscious customers while demonstrating corporate responsibility. This trend emphasizes the need for advanced thermoforming machines that balance high performance with sustainability in the food packaging industry.

Custom Thermoformed Packaging for Different Food Industries

Custom food packaging solutions play a vital role in enhancing brand identity and product differentiation. With thermoforming machines, manufacturers can design tailored packaging that fits specific product dimensions, shapes, and functional requirements. From bakery trays to multi-compartment meal containers, thermoforming machine for food packaging enables creative designs that improve both aesthetics and usability. This flexibility allows thermoform packaging manufacturers to meet diverse industry needs efficiently.

The dairy, bakery, frozen food, and ready-to-eat meal sectors all benefit from plastic thermoforming packaging produced by specialized food packaging machines. Thermoforming machines allow for airtight sealing, leak-proof designs, and durable containers that maintain food quality throughout storage and transportation. By leveraging thermoforming machine manufacturing technologies, companies can produce packaging that caters to the specific requirements of each sector, enhancing consumer satisfaction and trust.

Customization also extends to branding and marketing considerations. Labels, embossed logos, and unique container shapes can be incorporated directly during thermoforming machine production, creating distinctive food packaging that resonates with consumers. Thermoforming machines thus serve as essential tools for businesses aiming to differentiate their products while delivering high-quality, functional, and visually appealing food packaging solutions.

How to Choose the Right Thermoforming Machine for Your Needs

Selecting the appropriate thermoforming machine for food packaging requires careful consideration of production capacity, material compatibility, and product specifications. Businesses must evaluate their food packaging machines requirements in terms of volume, container shapes, and desired cycle times. By analyzing operational goals, manufacturers can choose thermoforming machines that maximize efficiency and minimize waste while ensuring consistent food packaging quality.

Material selection is another critical factor in thermoforming machine manufacturing. Different plastics, such as PET, PP, PS, and PLA, require specific machine configurations to achieve optimal plastic thermoforming packaging properties. Advanced thermoforming machine production systems can adjust heating, vacuum, and stretching parameters automatically, allowing for precision in creating food-grade thermoforming plastic containers suitable for various applications.

Companies should also consider maintenance, energy efficiency, and automation features when evaluating thermoforming machine manufacturers. Modern food packaging machines often include remote monitoring, intelligent software controls, and integrated lubrication systems to ensure long-term reliability. By choosing high-quality thermoforming machines, businesses can achieve a balance between production efficiency, product quality, and operational sustainability.

Global Trends in Thermoformed Food Packaging

The food packaging industry is witnessing a global shift toward sustainability, automation, and innovation. Thermoforming technology in food industry continues to evolve, driven by consumer demand for eco-friendly, visually appealing, and functional packaging. Thermoforming machines are increasingly designed to handle recyclable and biodegradable food-grade thermoforming plastic, allowing manufacturers to meet regulatory requirements while reducing environmental impact.

Automation and smart technology are also transforming thermoforming machine production. Advanced plastic packaging machines now incorporate sensors, AI-driven quality control, and real-time monitoring to optimize efficiency and consistency. These innovations make food packaging machines more adaptable to changing market demands, enabling businesses to stay competitive in the fast-paced global thermoforming machines market.

Another trend is the emphasis on custom food packaging solutions for niche markets. Companies are increasingly seeking thermoform packaging manufacturers capable of producing specialized containers, multi-compartment trays, and unique designs that cater to consumer preferences. Thermoforming machine for food packaging provides the flexibility, precision, and scalability needed to address these demands, reinforcing its central role in the modern food packaging ecosystem.

INPAK: Your Trusted Partner in Advanced Thermoforming Solutions

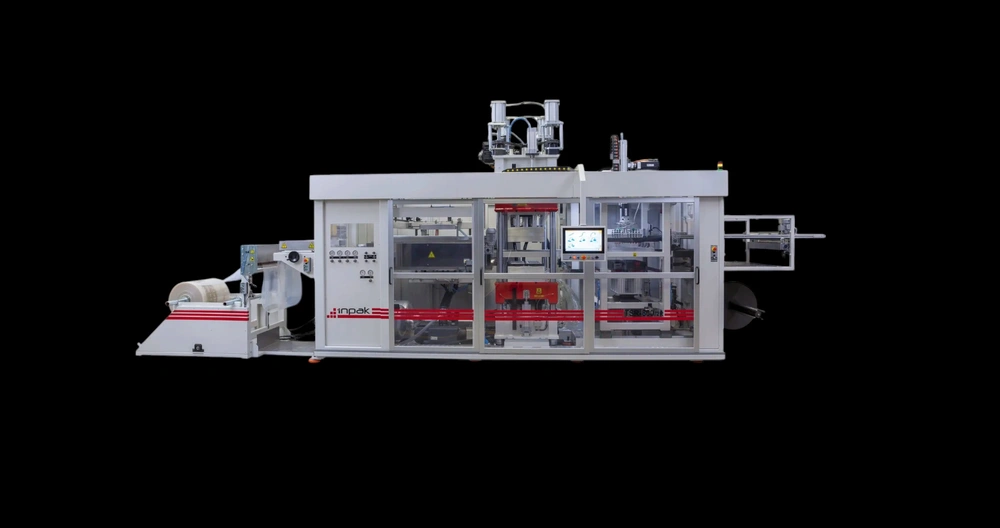

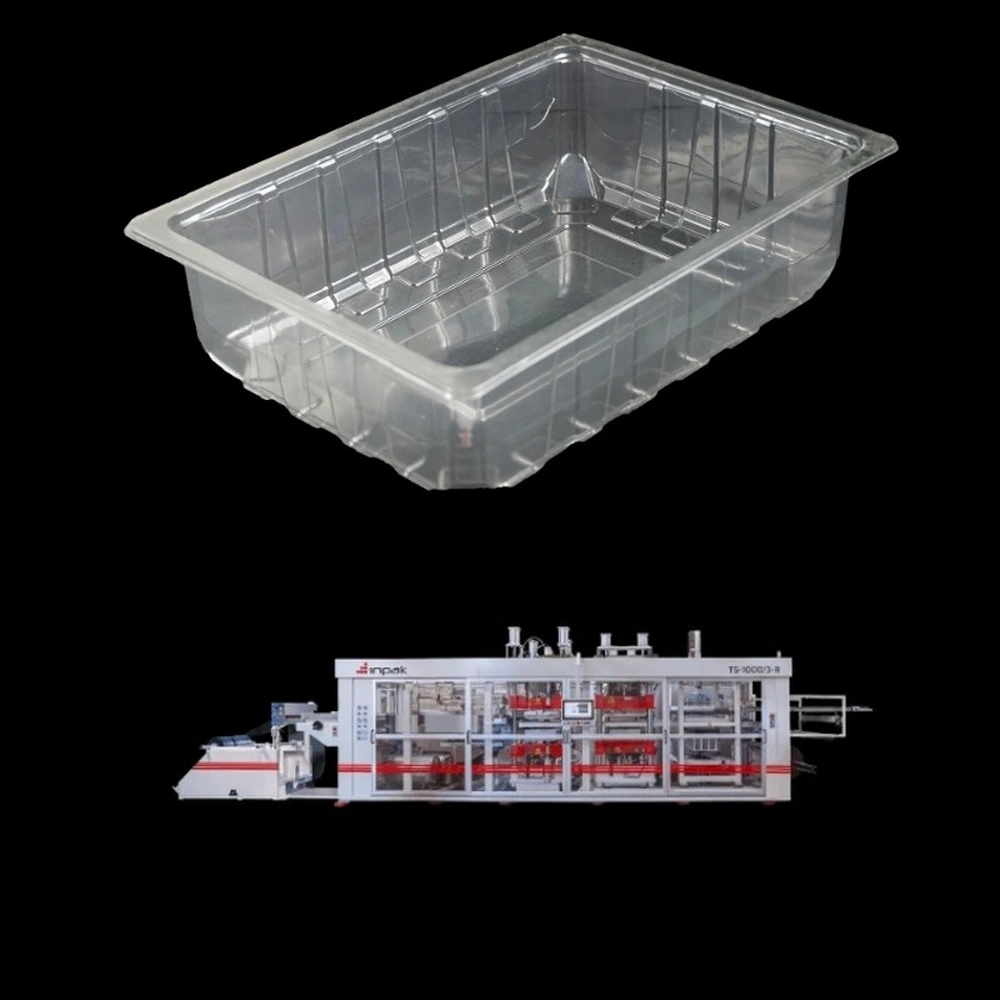

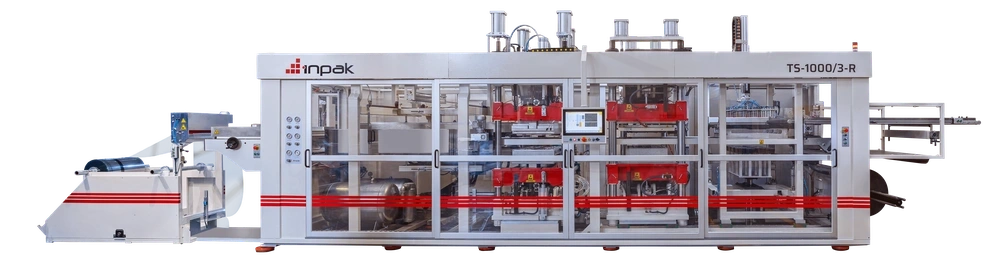

INPAK stands out among thermoforming machine manufacturers for its commitment to innovation, efficiency, and sustainability. By offering a range of thermoforming machines, including vacuum forming and automated systems, INPAK enables companies to optimize their food packaging machines operations while achieving consistent, high-quality results. Their thermoforming machine production emphasizes precision, durability, and adaptability to meet the diverse needs of the food packaging industry.

INPAK’s plastic thermoforming packaging solutions are designed with advanced technology, including servo-driven transport, sensitive positioning, and automatic lubrication systems. These features ensure that thermoforming machines deliver reliable performance and minimize downtime. By leveraging INPAK’s expertise, businesses can produce eco-friendly thermoformed packaging that aligns with modern sustainability standards and meets consumer expectations.

As a trusted thermoforming machine supplier, INPAK provides comprehensive support, from initial machine selection to installation and maintenance. Companies seeking custom food packaging solutions can benefit from INPAK’s tailored approach, ensuring that every food packaging machine delivers optimal results. By partnering with INPAK, manufacturers can elevate their production capabilities, adopt cutting-edge thermoforming technology in food industry, and maintain a competitive edge in the evolving food packaging market.