Advanced Thermoformed Packaging Trays for the Packaging Industry

The packaging industry has witnessed significant advancements with the integration of thermoformed packaging trays. These trays have become an indispensable element in modern packaging solutions due to their versatility and ability to meet the demanding needs of various sectors, including food, medical, and consumer goods. Their tailored designs and robust performance ensure products are protected during transport and storage while enhancing the overall presentation. Innovations in thermoforming machines have enabled manufacturers to produce trays with higher precision, consistent quality, and at greater speeds, reinforcing their role as essential components in packaging lines.

Table of Contents

Incorporating thermoformed trays for food packaging offers hygienic and durable containment, crucial for maintaining product freshness and safety. These trays are engineered using advanced materials and manufacturing processes to withstand different environmental conditions, such as moisture, temperature variations, and mechanical impacts. The lightweight nature of these trays also contributes to reducing transportation costs and environmental footprints, making them a preferred choice among environmentally conscious brands. Moreover, customization options in shape, size, and design allow businesses to develop unique packaging that appeals to consumer preferences and complies with regulatory standards.

As the demand for efficient packaging solutions grows, manufacturers rely heavily on plastic packaging machines capable of producing complex tray designs with precision and speed. This has fueled innovations in thermoforming machine manufacturing and the emergence of suppliers dedicated to delivering state-of-the-art equipment. By harnessing advanced automation and software integration, these machines support flexible production runs, minimizing waste and operational costs. The continual evolution of these technologies ensures that the packaging industry can meet future challenges while maintaining high-quality standards and sustainability goals.

Advanced Thermoformed Packaging Trays for the Packaging Industry

What Are Thermoformed Packaging Trays?

Thermoformed packaging trays are molded plastic containers created through a process where a heated plastic sheet is formed over a mold, then cooled and trimmed to the desired shape. This manufacturing method produces lightweight, durable, and precise trays that protect products while providing an attractive display. Unlike traditional packaging, thermoformed trays can be tailored to specific product dimensions and requirements, allowing for optimal fit and function. Their seamless construction enhances hygiene and durability, making them ideal for food and sensitive product packaging.

The production of these trays involves heating a plastic sheet until pliable, followed by forming it over a mold using vacuum, pressure, or mechanical means to capture detailed shapes and contours. After forming, the trays undergo trimming and finishing processes to remove excess material and create final products ready for packaging applications. This process is highly efficient and adaptable, supporting both high-volume production and customized runs. The technology behind the thermoforming machine production plays a crucial role in defining the quality, precision, and performance of the trays produced.

Thermoformed trays are widely appreciated in industries that require reliable packaging solutions capable of preserving product integrity. Their versatility spans packaging fresh produce, meats, pharmaceuticals, electronics, and more. The ability to integrate different features such as compartments, lids, and locking mechanisms adds functional value. Consequently, these trays not only serve a protective purpose but also contribute significantly to branding and consumer experience, influencing purchasing decisions through their visual appeal and usability.

Common Applications of Thermoformed Packaging Trays

The use of thermoformed trays for packaging extends across numerous sectors, reflecting their adaptability and functional benefits. In the food industry, these trays are commonly used to package fresh and processed foods such as fruits, vegetables, meats, bakery items, and ready-to-eat meals. Their ability to maintain freshness and provide barrier protection against contaminants is essential for ensuring food safety and extending shelf life. Additionally, thermoformed trays often comply with regulatory requirements related to food contact materials, offering peace of mind to both manufacturers and consumers.

Beyond food, the medical and pharmaceutical industries rely on thermoformed trays to package medical devices, surgical instruments, and consumables in sterile conditions. The trays can be customized to hold specific tools securely, reducing the risk of contamination and damage during transport and storage. Their design flexibility allows for easy access during medical procedures, enhancing workflow efficiency and safety. This sector values the precision and quality consistency that advanced thermoforming machines deliver in producing such critical packaging.

Consumer goods, including electronics, cosmetics, and industrial components, also benefit from thermoformed packaging trays. These trays provide protection against mechanical shocks and environmental factors, preserving product integrity until use. The ability to create visually appealing and branded packaging supports marketing efforts and helps products stand out on retail shelves. As industries seek to reduce environmental impacts, trays manufactured using recyclable or biodegradable materials are gaining traction, further broadening the application scope of thermoformed packaging.

How Thermoforming Machines Works in Tray Production

Thermoforming machines operate by heating plastic sheets to a pliable state and then shaping them over molds to create detailed packaging trays. The process begins with feeding the sheet into the machine, where heaters raise the temperature uniformly. This step requires precise temperature control to ensure the plastic reaches the optimal forming point without degradation. Once heated, the sheet is positioned over or into a mold cavity, and vacuum or pressure is applied to conform the sheet to the mold’s contours.

The forming phase is critical, as it defines the tray’s shape, thickness, and structural properties. Machines equipped with advanced servo drives and vacuum forming machine technology ensure that the material distribution is even, minimizing defects such as thinning or wrinkles. Following molding, the trays are cooled rapidly to maintain their shape and structural integrity. Once set, trimming systems remove excess material, producing finished trays that meet stringent dimensional and quality standards.

Modern thermoforming machine suppliers integrate automation and control systems to enhance production efficiency and consistency. Features like programmable logic controllers (PLC), human-machine interfaces (HMI), and remote access capabilities allow operators to monitor and adjust processes in real-time. This results in reduced downtime, improved quality control, and greater flexibility in producing trays of varying sizes and designs. As technology evolves, thermoforming machines continue to advance in precision and speed, supporting the packaging industry’s growing demands.

Advanced Thermoformed Packaging Trays for the Packaging Industry

Key Advantages of Using Thermoformed Trays in Packaging

One of the primary benefits of thermoformed packaging trays is their ability to deliver customized solutions that fit products perfectly. This tailored approach reduces material waste and improves product protection, decreasing the risk of damage during handling and transportation. Their lightweight construction also contributes to overall packaging efficiency by reducing shipping costs and carbon footprint. Compared to traditional rigid containers, thermoformed trays provide superior design freedom, allowing for innovative shapes and compartments tailored to specific product requirements.

Durability and hygiene are also significant advantages. Thermoformed trays are designed to resist impacts, moisture, and chemical exposure, making them ideal for food and medical applications where contamination control is crucial. Their seamless design eliminates crevices where bacteria could accumulate, and their compatibility with sterilization methods enhances safety. Additionally, these trays are often recyclable or produced from biodegradable materials, aligning with increasing environmental regulations and consumer preferences for sustainable packaging.

Finally, the production speed and cost-effectiveness offered by modern plastic packaging machines make thermoformed trays attractive to manufacturers. High-speed production cycles supported by advanced thermoforming machine manufacturing reduce labor costs and improve throughput. The energy efficiency of newer machines also lowers operational expenses. This combination of performance, quality, and sustainability has positioned thermoformed trays as a leading choice in packaging solutions across diverse industries.

Materials Used in Thermoformed Tray Manufacturing

A variety of materials are used in the manufacture of thermoformed trays for food packaging and other applications, each selected for its specific properties such as clarity, strength, barrier protection, and environmental impact. Common plastics include PET (polyethylene terephthalate), CPET (crystallized PET), PP (polypropylene), PVC (polyvinyl chloride), PS (polystyrene), OPS (oriented polystyrene), and PLA (polylactic acid). These materials offer different balances of durability, flexibility, and recyclability, enabling manufacturers to tailor tray properties to the end-use requirements.

PET and CPET are popular choices in food packaging due to their excellent clarity, strength, and heat resistance. They provide good barrier properties against moisture and oxygen, which help extend product shelf life. PP offers high chemical resistance and is often used where microwavability is required. PVC is favored for its clarity and impact resistance but has seen reduced use due to environmental concerns. PS and OPS provide rigid and cost-effective options for various packaging forms, while PLA offers a biodegradable alternative derived from renewable resources, appealing to sustainability-focused brands.

The selection of materials also depends on compatibility with thermoforming machines and processing conditions. Certain plastics require specific temperature profiles and forming techniques to achieve optimal results. Advances in machine design, such as adjustable heating systems and servo-driven transport chains, allow for the efficient processing of a wider range of materials. This flexibility enhances manufacturers’ ability to meet diverse market demands while maintaining product quality and regulatory compliance.

Types of Thermoforming Machines for Tray Production

The market offers various types of thermoforming machines designed specifically for tray production, each catering to different production volumes, material types, and complexity of tray designs. Basic machines operate using vacuum forming, where the plastic sheet is drawn onto the mold using suction. More advanced machines combine vacuum with pressure forming, enhancing detail and surface finish, especially for intricate tray designs. The choice of machine impacts the quality, cycle time, and versatility of tray production.

High-performance models incorporate servo-driven transport systems, allowing precise control of sheet movement and stretching to optimize material distribution. Some machines feature multi-station designs for integrated processes such as heating, forming, trimming, and stacking in a single cycle, increasing throughput and automation. Others offer modular configurations, enabling manufacturers to adapt the machine to evolving production needs or incorporate additional equipment such as pre-heaters and conveyor systems.

Leading thermoforming machine manufacturers like INPAK emphasize integrating cutting-edge technology, including advanced human-machine interfaces, remote monitoring, and automatic lubrication systems. These features enhance operator efficiency and machine reliability while reducing maintenance requirements. By selecting the appropriate machine type, businesses can achieve a balance between investment cost, production capacity, and product quality, ensuring competitive advantages in the packaging sector.

Advanced Thermoformed Packaging Trays for the Packaging Industry

INPAK: Professional Thermoforming Machine Solutions

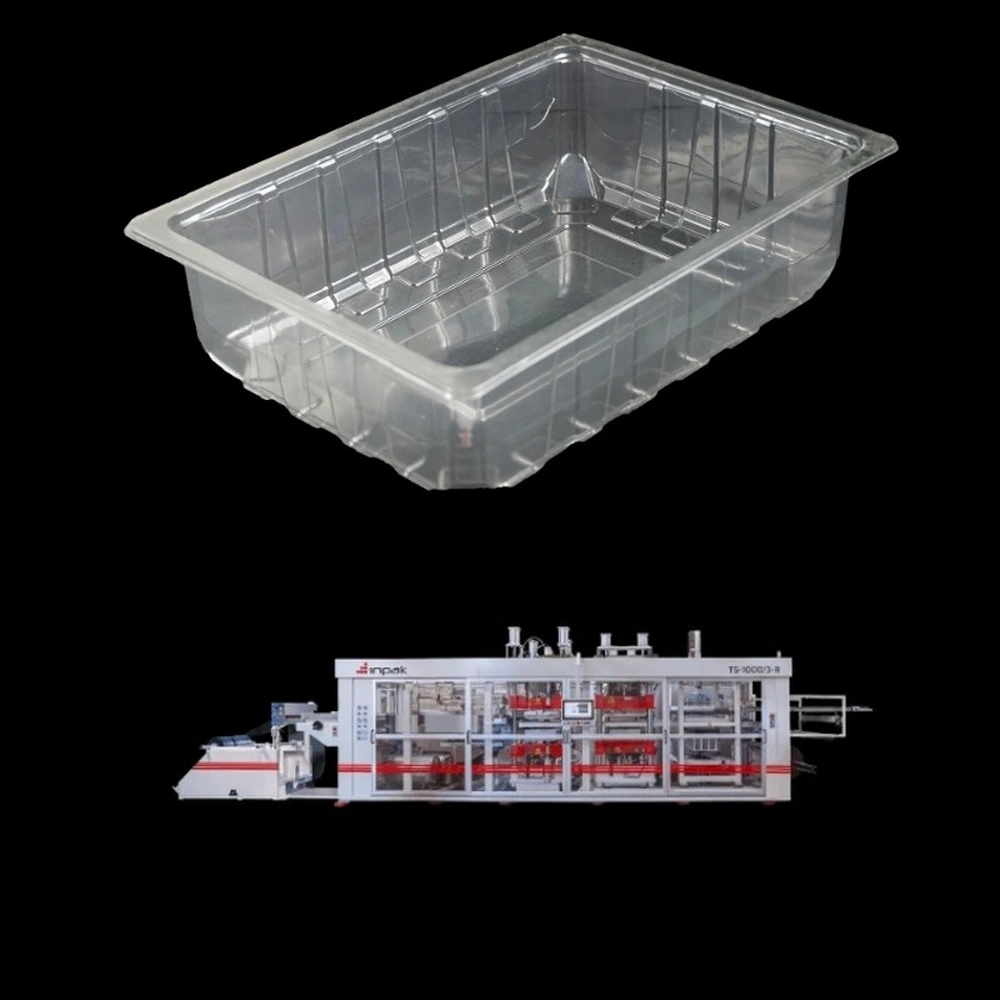

INPAK stands out as a premier thermoforming machine supplier, offering a comprehensive portfolio of advanced machines tailored to the needs of the packaging industry. Their product range includes models like TSR-800, TS-800, TS-850, and TS-1000, alongside complementary equipment such as pre-heaters and elevator conveyor systems. These machines are engineered with a focus on precision, efficiency, and durability, addressing the demands of food, medical, and industrial packaging sectors.

One of INPAK’s key strengths lies in their integration of sophisticated features such as an ergonomic human-machine interface powered by proprietary software, enabling intuitive operation and real-time process control. Remote access capabilities allow for immediate fault finding and machine adjustments, minimizing downtime. Their machines also include variable heater configurations with ceramic heating elements, automatic lubrication systems, servo-driven transport chains, and servo plug assists that optimize material distribution and ensure homogenous product quality.

INPAK’s commitment to innovation extends to the long-life mechanical systems used in their machines, featuring special needle bearings and gapless toggle joints that reduce wear and maintenance. The inclusion of stacking systems supporting multiple stacking sequences further enhances production flexibility. By choosing INPAK, businesses gain access to reliable, state-of-the-art thermoforming machines that improve productivity, reduce operational costs, and elevate packaging quality in an increasingly competitive market.