Packaging Thermoforming Technology Redefined by INPAK

Packaging thermoforming has emerged as one of the most innovative processes in the plastic packaging machine industry. At INPAK, we lead this transformation by offering high-performance thermoforming machines tailored for modern production demands. Our deep industry experience allows us to deliver solutions that are both efficient and adaptable to a wide range of applications, from food to industrial sectors.

Table of Contents

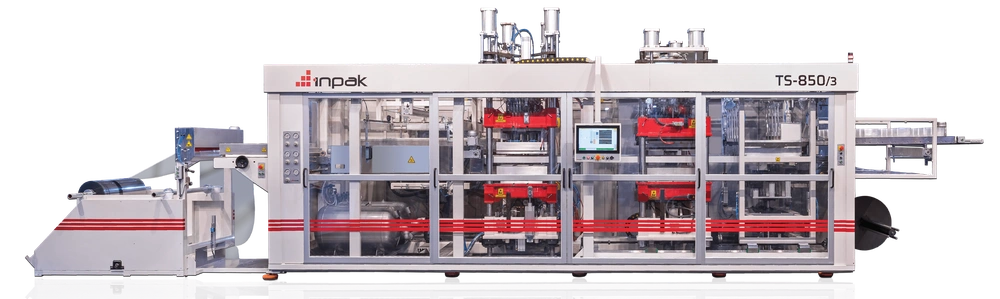

What sets INPAK apart is our dedication to precision and quality. Each thermoforming packaging machine we manufacture is built using next-generation control systems and robust hardware to ensure consistent product integrity. Whether you’re seeking a thermoforming machine for food packaging or looking to streamline your existing packaging line, INPAK delivers superior results.

Our machines have redefined the thermoformed packaging process by ensuring seamless integration, fast cycle times, and reduced waste. INPAK is not only a thermoforming machine manufacturer but a trusted partner in revolutionizing the future of thermoforming packaging with sustainable, intelligent, and cost-effective solutions.

Packaging Thermoforming Technology Redefined by INPAK

What is Thermoforming Packaging?

Thermoforming packaging is a process that involves heating a plastic sheet to a pliable forming temperature, shaping it into a specific mold, and trimming it to create a usable product. This method is extensively used for producing thermoformed plastic packaging in various industries, especially in food and medical sectors. Thermoform packaging suppliers rely on this technique due to its efficiency, cost-effectiveness, and adaptability.

At INPAK, we utilize cutting-edge technologies in our thermoforming machines to ensure the highest quality in thermoforming food packaging. Our systems are engineered to work with a range of materials and molds, allowing businesses to create custom thermoformed packaging that meets their exact requirements. With precise control and consistent results, our plastic forming machines deliver superior performance every time.

As a leader in thermoforming machine supply, INPAK ensures that clients have access to the latest developments in the field. We support every phase of thermoforming packaging – from design to production – ensuring a smooth transition from raw material to finished product with minimal environmental impact and optimal output.

What are the Three Types of Thermoforming?

The three main types of thermoforming packaging include vacuum forming, pressure forming, and mechanical forming. Vacuum forming is the most common method, used widely in thermoforming machine manufacturing for creating food trays, clamshells, and other everyday items. INPAK’s advanced thermoforming machines are equipped to handle all three types with exceptional precision.

Pressure forming is used when fine detail and sharp definition are required. INPAK integrates pressure systems in our automatic thermoforming machine production lines to cater to high-performance packaging needs. Our clients trust us as their preferred thermoforming machine supplier for applications requiring intricate designs and tight tolerances in thermoform packaging.

Mechanical forming, although less common, offers advantages in specific applications requiring deep draws. INPAK’s customizable systems can be adapted for this technique, ensuring that thermoforming machine manufacturing companies can rely on us for complete and scalable solutions in industrial thermoforming machine production.

Next-Generation Thermoforming Machine Production Techniques

INPAK uses cutting-edge production methodologies in our thermoforming machine production processes. From precision CNC machining to modular assembly systems, our approach ensures quality and speed at every stage of manufacturing. As a result, our clients benefit from efficient thermoforming packaging machine manufacturing with reduced lead times and consistent performance.

We emphasize lean production and smart factory integration to minimize waste and boost output. Our facilities are designed to support large-scale thermoforming machine manufacturing while maintaining flexibility for custom builds. This approach positions us among the top thermoforming machine manufacturers in the region.

By constantly investing in R&D, we push the limits of what’s possible in plastic forming machines. Whether you’re launching a new line of thermoformed food packaging or upgrading an old unit, INPAK delivers innovative solutions that redefine industry standards in thermoforming packaging.

Packaging Thermoforming Technology Redefined by INPAK

Streamlined Manufacturing for Faster Thermoforming Machine Delivery

INPAK stands out with its streamlined production model that ensures faster delivery of thermoforming machines to clients around the world. From concept to completion, we handle every aspect of thermoforming machine manufacturing with speed and precision. This ensures our customers can launch or scale operations with minimal downtime.

Our vertically integrated operations reduce dependency on third-party suppliers, allowing us to control quality and timelines more effectively. For clients seeking urgent solutions, we provide flexible thermoforming machine supply options to meet even the tightest production schedules.

Through continuous improvement and automation, we reduce complexity and accelerate assembly timelines. Clients choose INPAK not just for our speed, but for our unmatched reliability in delivering thermoforming packaging machines that perform under the most demanding production conditions.

Smart Thermoforming Machines with IoT Integration

As industries shift toward smart manufacturing, INPAK leads the way by integrating IoT capabilities into our thermoforming machines. These intelligent systems offer remote diagnostics, predictive maintenance, and real-time performance analytics. This makes us a future-ready thermoforming machine producer and preferred choice for advanced packaging thermoforming solutions.

IoT integration transforms standard machines into smart assets. Clients can monitor production KPIs, troubleshoot issues, and adjust parameters without halting operations. This not only increases productivity but also improves decision-making based on accurate data.

By combining smart sensors and cloud connectivity, our thermoforming machines become an integral part of connected production ecosystems. Companies looking to embrace Industry 4.0 standards choose INPAK as their partner in automatic thermoforming machine production and digital transformation.

Sustainable Materials in Thermoforming Machine Production

Sustainability is at the heart of INPAK’s values. Our thermoforming packaging machines are designed to work efficiently with eco-friendly materials such as PLA, rPET, and biodegradable polymers. This allows our clients to reduce their environmental footprint while still achieving excellent results in thermoformed plastic packaging.

As a responsible thermoforming machine manufacturer, we also prioritize sustainable manufacturing practices. Our production methods minimize energy use, reduce material waste, and ensure that every plastic packaging machine we produce meets or exceeds global environmental standards.

INPAK supports brands transitioning to green packaging by offering guidance and technical expertise in sustainable thermoforming packaging. Our machines are compatible with recycled and compostable materials, helping clients meet regulatory requirements and sustainability goals without compromising efficiency.

Packaging Thermoforming Technology Redefined by INPAK

Advanced Heating and Forming Technologies in Thermoforming

INPAK integrates advanced heating systems into every thermoforming machine, ensuring rapid and uniform temperature distribution. This enhances material flexibility and precision forming, which are critical for high-quality thermoforming food packaging. Whether you’re forming deep-draw trays or intricate medical containers, our machines deliver consistent quality.

Our thermoforming machines are equipped with high-speed servo-driven components, smart temperature control, and modular forming stations. This ensures they meet the demands of both low- and high-volume production. We offer complete solutions for industrial thermoforming machine production, backed by decades of technical expertise.

With INPAK’s innovation in heating and forming, clients benefit from reduced cycle times, less scrap material, and superior product finish. These technological advantages make us one of the most reliable thermoforming machine manufacturing companies for global packaging solutions.

Packaging Thermoforming Technology Redefined by INPAK

INPAK: Revolutionizing Thermoforming Packaging Solutions

INPAK is more than a thermoforming machine supplier – we are innovators in the thermoforming packaging industry. Our mission is to equip manufacturers with advanced, sustainable, and customizable thermoforming machines that redefine production capabilities across multiple sectors.

From food-grade trays to specialized medical and industrial components, INPAK machines deliver unmatched reliability and performance. As a global thermoforming machine manufacturer, we proudly serve clients looking for complete, turnkey systems tailored to their specific requirements.

If you are looking to upgrade your thermoforming packaging machine, source a trusted thermoforming machine producer, or enter the market with cutting-edge technology, INPAK is your go-to partner. Our commitment to quality, innovation, and service ensures your success in the evolving world of packaging thermoforming.