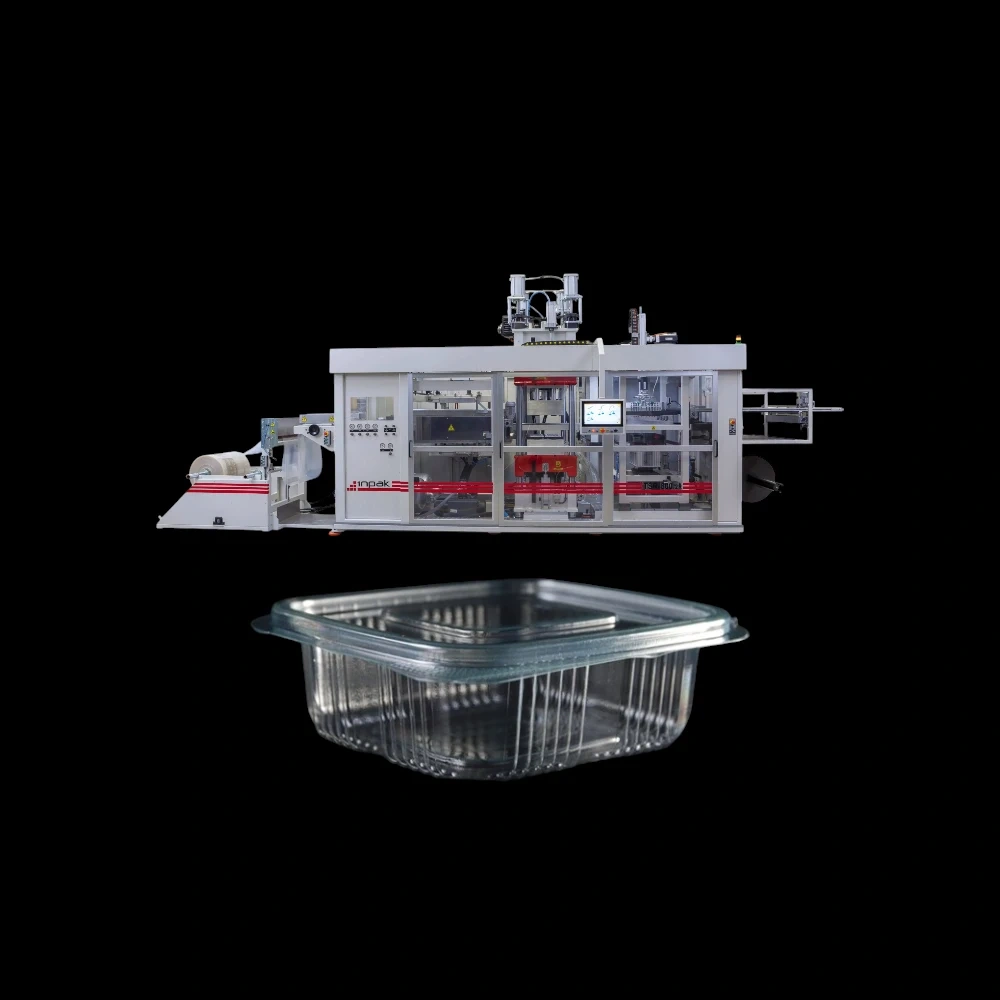

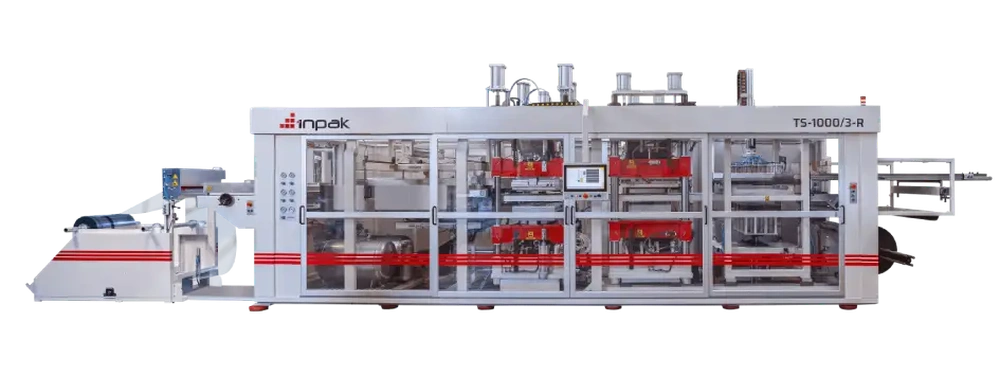

3 Station Plastic Thermoforming Machines for Flexible Production

3 station plastic thermoforming machines are designed to provide maximum flexibility for modern manufacturing environments. Unlike traditional single-station machines, these multi-station systems allow simultaneous forming, trimming, and stacking of plastic products, ensuring continuous production without delays. For industries such as food packaging, medical supplies, and consumer goods, this flexibility is crucial to meet varying product demands efficiently while maintaining high-quality standards.

Table of Contents

Thermoforming machines excel in handling a wide range of materials, including PET, PP, PS, PVC, and PLA, enabling manufacturers to create both lightweight and heavy-gauge products. With custom thermoforming solutions, businesses can adjust molds, sheet thickness, and heating parameters to produce diverse packaging designs without needing multiple separate machines. This makes 3 station thermoforming machines an ideal solution for companies aiming for versatile and high-speed production lines.

In addition, industrial thermoforming equipment like the 3 station plastic thermoforming machine enhances operational efficiency by minimizing manual intervention. Automated sheet feeding, vacuum forming, and precise stacking allow for reduced labor costs and consistent product quality. For companies investing in flexible production thermoforming, these machines offer a reliable, long-term solution that combines speed, precision, and adaptability, enabling them to stay competitive in a dynamic market.

What is a 3-Station Plastic Thermoforming Machine?

A 3 station plastic thermoforming machine is a specialized type of plastic thermoforming machine designed to maximize efficiency and precision in producing molded plastic products. Unlike traditional single-station machines, the 3 station thermoforming machine features three separate working stations, which typically include heating, forming, and trimming. This configuration allows continuous production, reducing downtime and enabling manufacturers to produce a higher volume of quality parts with consistent accuracy.

The key innovation behind the 3 station plastic thermoforming machine lies in its ability to manage multiple processes simultaneously. While one station is actively heating a plastic sheet, the second station forms the heated sheet into its intended shape, and the third station trims or finishes the product. This overlapping workflow ensures that production lines operate at optimal speed, making it suitable for industries that demand large-scale manufacturing, such as food packaging and medical equipment.

Additionally, a 3 station thermoforming machine offers enhanced flexibility for various plastic materials. It supports different sheet types, including PET, PP, PVC, PS, and PLA, while accommodating both thin and heavy-gauge plastics. Manufacturers looking for flexible production thermoforming can benefit from this machine’s ability to switch quickly between product types without extensive downtime, ensuring adaptability to market demands and seasonal variations.

Key Advantages of 3-Station Thermoforming Machines

One of the primary benefits of a 3 station plastic thermoforming machine is its ability to significantly increase production efficiency. By running three stations concurrently, manufacturers can achieve higher throughput without compromising quality. The integration of advanced automation and precision controls in a high-speed thermoforming machine ensures consistent molding results, reducing material waste and operational costs over time.

Another advantage of the 3 station thermoforming machine is its versatility in product applications. These machines can produce a wide range of items, from food containers and trays to industrial components, making them an ideal choice for businesses that require custom thermoforming solutions. The ability to adjust settings for different sheet thicknesses and shapes provides manufacturers with the flexibility to meet diverse customer requirements while maintaining a uniform production standard.

Furthermore, multi-station thermoforming machines often include features such as automated vacuum systems and advanced heating controls. These innovations allow precise control over material distribution and temperature, ensuring that products maintain structural integrity and aesthetic quality. By leveraging these advantages, companies using industrial thermoforming equipment can maintain a competitive edge while expanding production capabilities efficiently.

Applications of Multi-Station Thermoforming in Various Industries

3 station plastic thermoforming machines are widely utilized across numerous industries where plastic products are essential. In the food packaging sector, these machines produce thermoformed trays, containers, and lids that meet strict hygiene and safety standards. The ability to operate at high speed makes them particularly valuable for large-scale operations where continuous output is necessary.

In addition to food packaging, the medical and pharmaceutical industries benefit from multi-station thermoforming technology. Machines like the thermoforming machine for packaging medical devices, surgical instruments, and sterile kits efficiently, ensuring products are uniformly shaped and securely packaged. The precision offered by vacuum thermoforming machines guarantees that delicate items are formed without deformation, maintaining quality and safety compliance.

The industrial sector also leverages 3 station thermoforming machines for manufacturing heavy-gauge parts and enclosures. Companies producing automotive, electronics, or consumer goods utilize these machines for plastic sheet forming machine applications, as they can handle larger sheets and more complex molds. This adaptability makes the 3 station plastic thermoforming machine a versatile investment for businesses seeking to diversify their production portfolio.

How Does a 3-Station Thermoforming Machine Improve Production Efficiency?

Production efficiency is at the core of the 3 station plastic thermoforming machine design. By enabling simultaneous heating, forming, and trimming, these machines eliminate bottlenecks that occur in traditional single-station operations. The result is faster production cycles and consistent output, allowing manufacturers to meet high-volume demands with minimal downtime.

The advanced automation incorporated in high-speed thermoforming machines also contributes to improved efficiency. Integrated controls, servo-driven transport systems, and automated stacking solutions reduce manual intervention, decreasing the risk of errors and ensuring uniform product quality. These systems are particularly advantageous for flexible production thermoforming, as they allow quick changeovers between product types without sacrificing performance.

Energy efficiency is another critical factor. Multi-station thermoforming machines are engineered to optimize heat distribution and reduce wasted energy, lowering operational costs. By combining precise temperature management with effective material utilization, these machines offer manufacturers the dual benefits of speed and cost savings. Companies investing in industrial thermoforming equipment can achieve higher profit margins while maintaining environmentally responsible production practices.

Customizable Thermoforming Solutions for Different Plastic Products

The adaptability of a 3 station plastic thermoforming machine is essential for businesses with diverse product lines. These machines can be customized to accommodate varying sheet sizes, thicknesses, and materials, enabling manufacturers to produce both standard and specialized products. Custom thermoforming solutions ensure that unique packaging or component requirements are met without extensive retooling.

In the food industry, for instance, a thermoforming machine for packaging can be configured to create different tray sizes, compartments, and lid designs. Similarly, manufacturers producing industrial components can adjust the machine to handle heavier plastics or complex geometries. This flexibility is critical for companies seeking automated thermoforming systems that provide both speed and precision across multiple product categories.

Moreover, 3 station thermoforming machines often include optional features such as vacuum forming, automated stacking, and servo-plug assist systems. These enhancements improve material distribution, reduce waste, and guarantee consistent quality. By offering custom thermoforming solutions, these machines allow businesses to expand their product offerings, respond quickly to market trends, and maintain a competitive edge in fast-paced industries.

Comparing Single-Station vs. Multi-Station Thermoforming Machines

Single-station plastic thermoforming machines operate sequentially, with heating, forming, and trimming performed one step at a time. While these machines are suitable for lower-volume production, they often encounter limitations in speed and efficiency. In contrast, the 3 station plastic thermoforming machine enables flexible production thermoforming by performing multiple operations simultaneously, resulting in faster throughput and consistent product quality.

Another difference lies in adaptability. Single-station machines may require longer changeover times when switching product types, while multi-station thermoforming machines can accommodate various sheets, molds, and product configurations more efficiently. This advantage makes the 3 station thermoforming machine ideal for businesses that require custom thermoforming solutions or produce multiple product lines in a single facility.

Cost considerations also favor multi-station thermoforming machines over single-station alternatives in the long term. Although initial investment may be higher, the reduction in labor, energy, and material waste often offsets the upfront cost. Companies using industrial thermoforming equipment benefit from improved production cycles, higher output, and a more versatile manufacturing platform, making 3 station plastic thermoforming machines a strategic investment for growth-oriented operations.

INPAK – 3 Station Plastic Thermoforming Machines for Flexible Production

Why Choose INPAK for High-Quality Thermoforming Machines?

INPAK is a leading thermoforming machine manufacturer renowned for delivering advanced INPAK thermoforming machines that cater to diverse industrial needs. Our 3 station plastic thermoforming machines combine precision engineering, high-speed automation, and durable construction, ensuring reliable performance across multiple applications. With INPAK, manufacturers gain access to custom thermoforming solutions that enhance production efficiency and product quality.

Our machines are equipped with features such as vacuum forming capabilities, adjustable heater configurations, and servo-driven transport systems. These innovations enable thermoforming for food packaging, industrial components, and heavy-gauge applications, providing unmatched versatility. By investing in high-speed thermoforming machines from INPAK, businesses can achieve superior throughput, minimize waste, and maintain a competitive advantage in their respective markets.

Furthermore, INPAK prioritizes flexible production thermoforming solutions tailored to each client’s needs. Whether producing consumer goods, medical devices, or packaging solutions, our automated thermoforming systems offer scalable performance, energy efficiency, and precise control. Choosing INPAK ensures access to world-class industrial thermoforming equipment designed to maximize output, maintain product integrity, and support long-term operational success.